Depth indicator

A technology of depth indicator and indicator, which is used in elevators, lifting equipment in mines, transportation and packaging, etc., can solve the problems of difficult gearbox processing, inconvenient assembly and maintenance, and complex structure, and achieve outstanding economic benefits. , the effect of reducing manufacturing difficulty and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

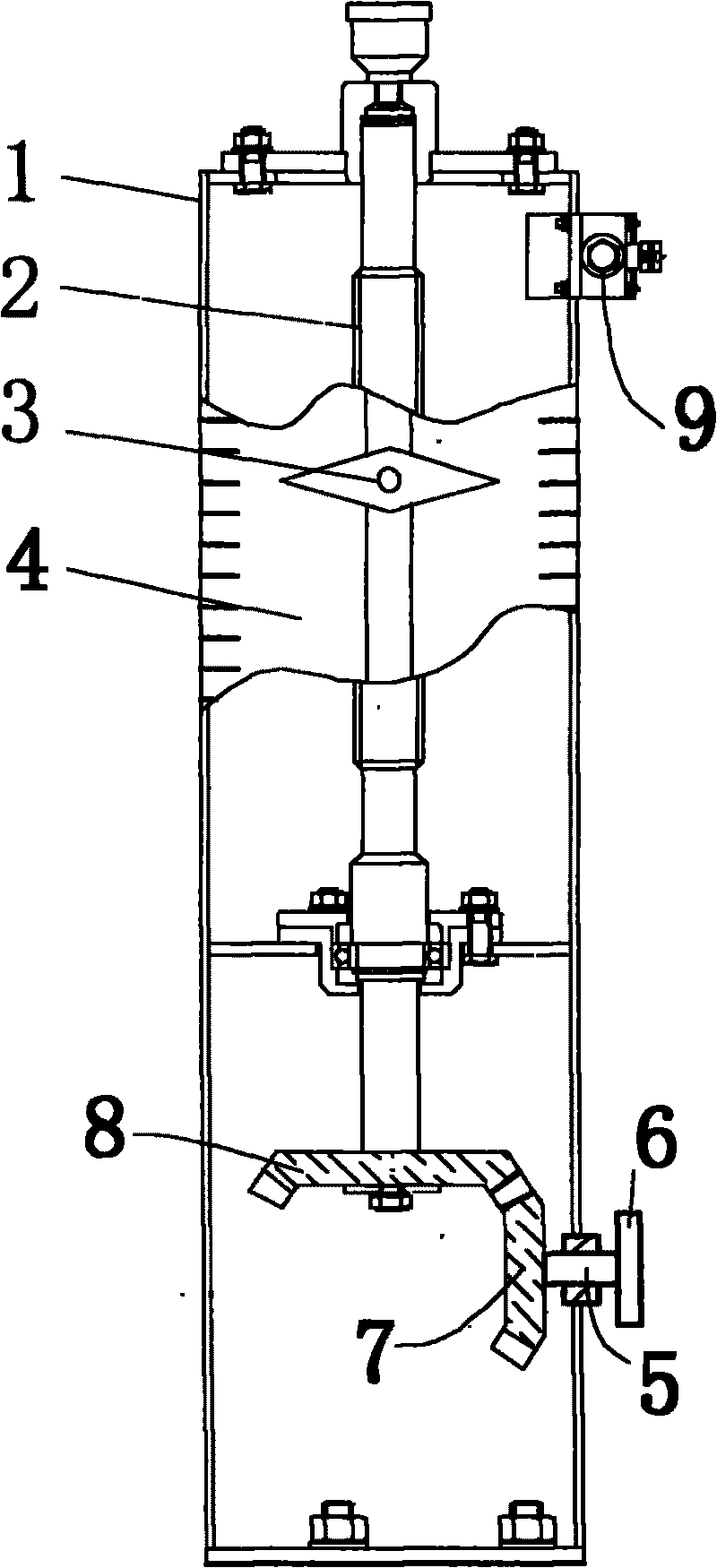

[0020] figure 1 Shown is a depth indicator, comprising a frame 1, and a rotatable screw 2 vertically installed on the frame 1, an indicator 3 is installed on the screw 2, a scale bar 4 is installed on the frame 1, and is movably connected to the machine frame. Transverse axis 5 one end on the frame 1 is installed runner 6, and bevel gear one 7 is installed in the other end, and bevel gear two 8 is installed in screw rod 2 lower ends, and bevel gear one 7 is engaged with bevel gear two 8. A warning device 9 is also installed on the frame 1 .

Embodiment 2

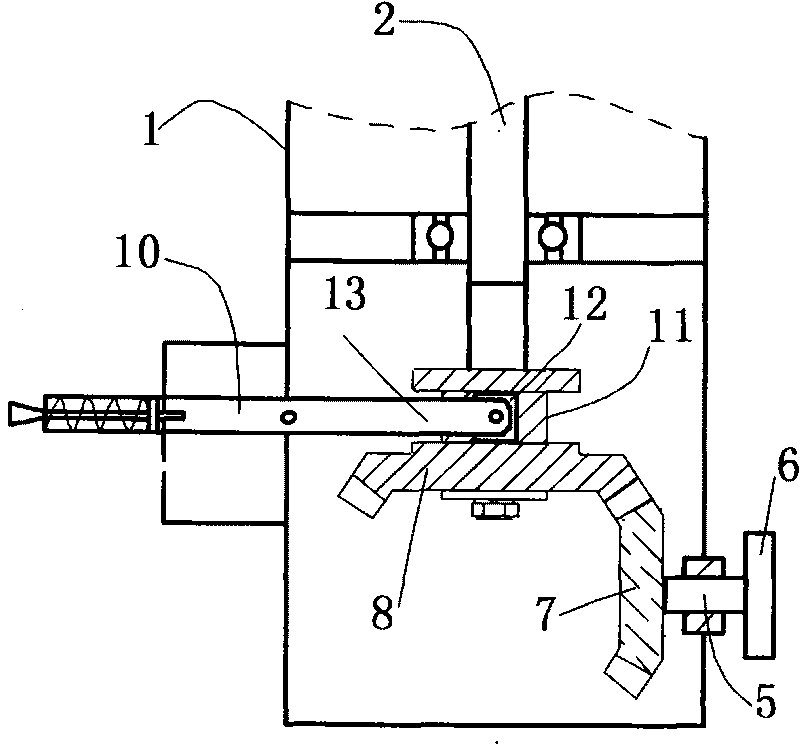

[0022] figure 2 Another depth indicator is shown, the bevel gear 2 8 can move axially along the screw rod 2, and the shift fork device 10 is installed on the frame 1, and the shift fork device 10 includes a driving rod 13 and a roller installed at the end of the driving rod 13 12. Bevel gear 2 8 is provided with dial groove 11, and roller 12 is inserted into dial groove 11. Shaking the driving lever 13 can make bevel gear 2 8 and bevel gear 1 7 separate or engage.

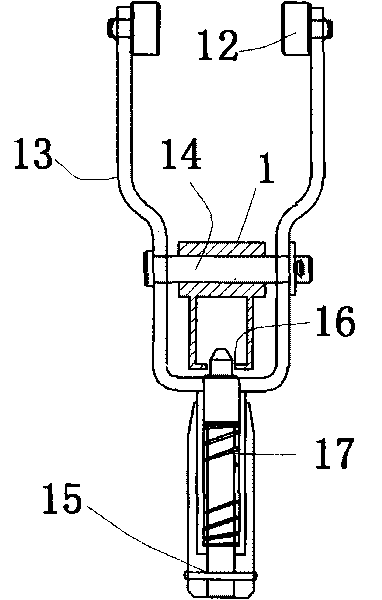

[0023] image 3 show figure 2 An embodiment of the shift fork device in the shown embodiment, the shift fork device includes a shift lever 13 and a roller 12 movably connected to the front end of the shift lever 13. It is flexibly connected and can make the driving lever 13 rotate around the pivot pin 14, the rear end of the driving lever 13 is equipped with a movable movable handle 15, and the front end of the movable handle 15 can be snapped into the positioning hole 16 on the frame 1, and the movable handle ...

Embodiment 3

[0025] Figure 4 Another depth indicator is shown. The shifting fork device 10 includes a dialing ring 21 that is movable in the dialing groove 11. The dialing ring 21 is fixedly connected to a locking device 23 through a connecting rod 22. The locking device 23 can be mounted on the frame 1. Move vertically, and can be fixed on the frame 1 at different positions. When the bevel gear 2 8 meshes with the bevel gear 1 7, the locking device 23 is released and moves vertically upwards, so that the bevel gear 2 8 and the bevel gear 1 7 Separate and lock the locking device 23 again to keep the bevel gear two 8 and the bevel gear one 7 in a separated state; The second bevel gear 8 is meshed with the first bevel gear 7, and the locking device 23 is locked again, so that the second bevel gear 8 and the first bevel gear 7 can be kept in the meshed state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com