Automobile power-driven automatic expanding footboard

An automatic retractable and pedal technology, which is applied to the layout of pedals or ladders, vehicle parts, transportation and packaging, etc., can solve the problems of rusty chains, large movement resistance, complicated manufacturing process, and high maintenance costs, so as to reduce noise sources, The effect of simplifying the processing process and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

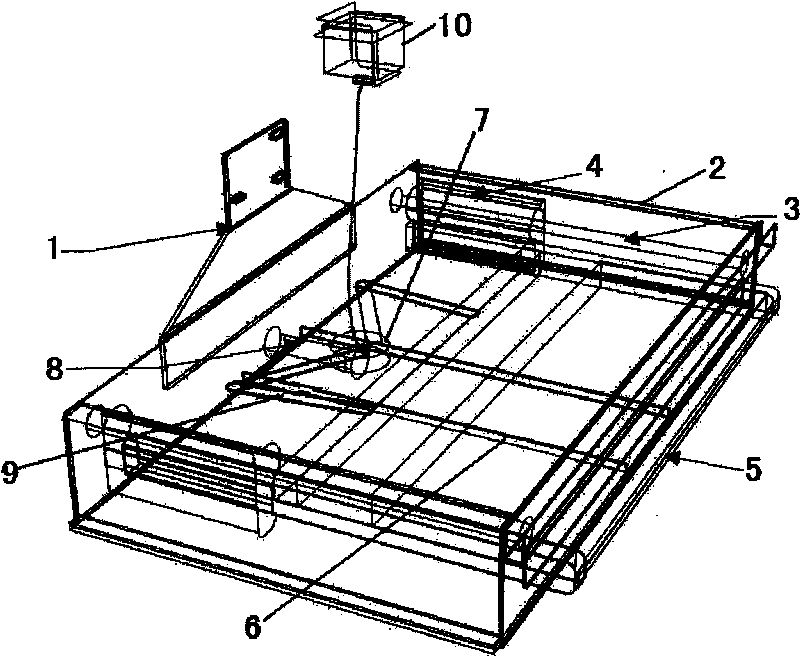

[0008] like figure 1 As shown, the present invention is realized in this way, it comprises support 1, support frame 2, slide bar 3, linear bearing 4, pedal 5, installation beam 6, motor 7, connecting rod 8, scissors type transmission rod 9, anti-collision The controller 10 is characterized in that the bracket 1 is connected to the support frame 2, and the inner walls on both sides of the support frame 2 are respectively connected with a slide bar 3, and the slide bar 3 is covered with a linear bearing 4, and one end of the linear bearing 4 is fixedly connected to the end of the pedal 5, and the support frame 2 The middle part of the bottom end is connected with a mounting beam 6, and a motor 7 is installed on the mounting beam 6, and the motor 7 is supported by a connecting rod 8. The motor 7 is symmetrically connected to a pair of scissor transmission rods 9 through the driven teeth of the gearbox, and the scissor transmission rod 9 is connected The pedal 5 and the motor 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com