Special kettle for electromagnetic oven

A technology for an induction cooker and a kettle body is applied in the field of special glass kettles for induction cookers, which can solve the problems of falling off the lid, water leakage, and water overflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

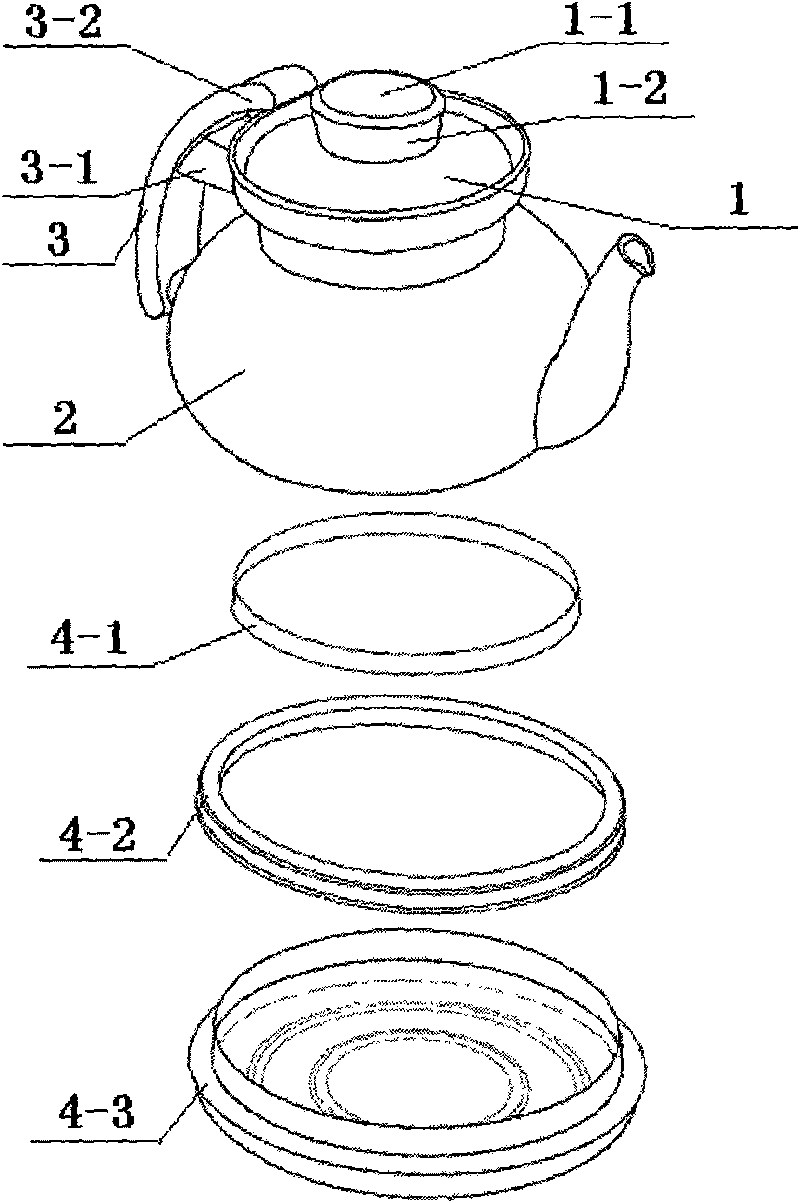

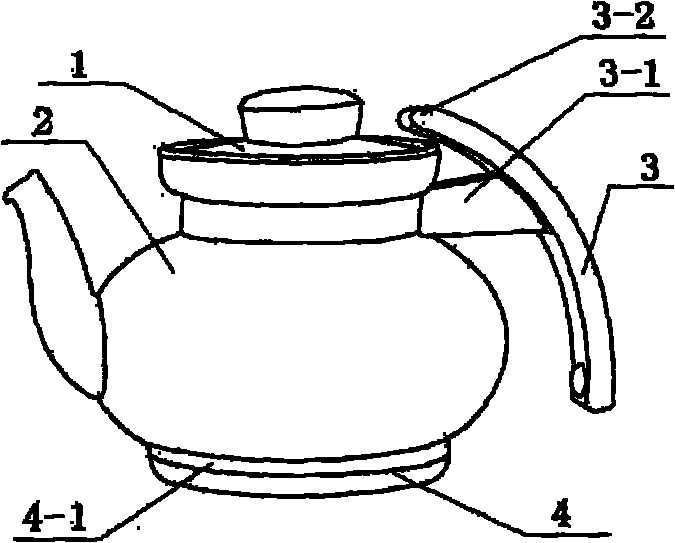

[0005] see Figure 1-2 , the specific embodiment adopts the following technical scheme: it is made up of pot lid 1, pot body 2, handle 3, pot bottom 4, handle 3 is y-shaped, the middle part 3-1 of y-shaped handle 3 and the neck of pot body 2 Connected, the upper part 3-2 of the y-shaped handle 3 protrudes about 1-2 cm in the middle of the pot body and is slightly higher than the edge of the spout; -1, heat-resistant silicone ferrule 4-2, stainless steel bottom plate 4-3, the stainless steel bottom plate 4-3 is connected to the bottom of the kettle body 2 through the heat-resistant silicone ferrule 4-2, and the stainless steel bottom plate 4-3 and the kettle body The outside of the joint is coated with adhesive, and then covered with a heat-resistant silicone ring 4-1. In this specific embodiment, when pouring water, the upper part 3-2 of the y-shaped handle 3 clamps the pot lid 1, and there is no need to press the pot lid 1 with hands, which will not cause the pot lid to fall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com