Device of chemical vapor deposition diamond or other substances

A chemical vapor deposition and diamond technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of large gas consumption and high cost, and achieve environmental protection, consumption saving, and good economic benefits and the effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

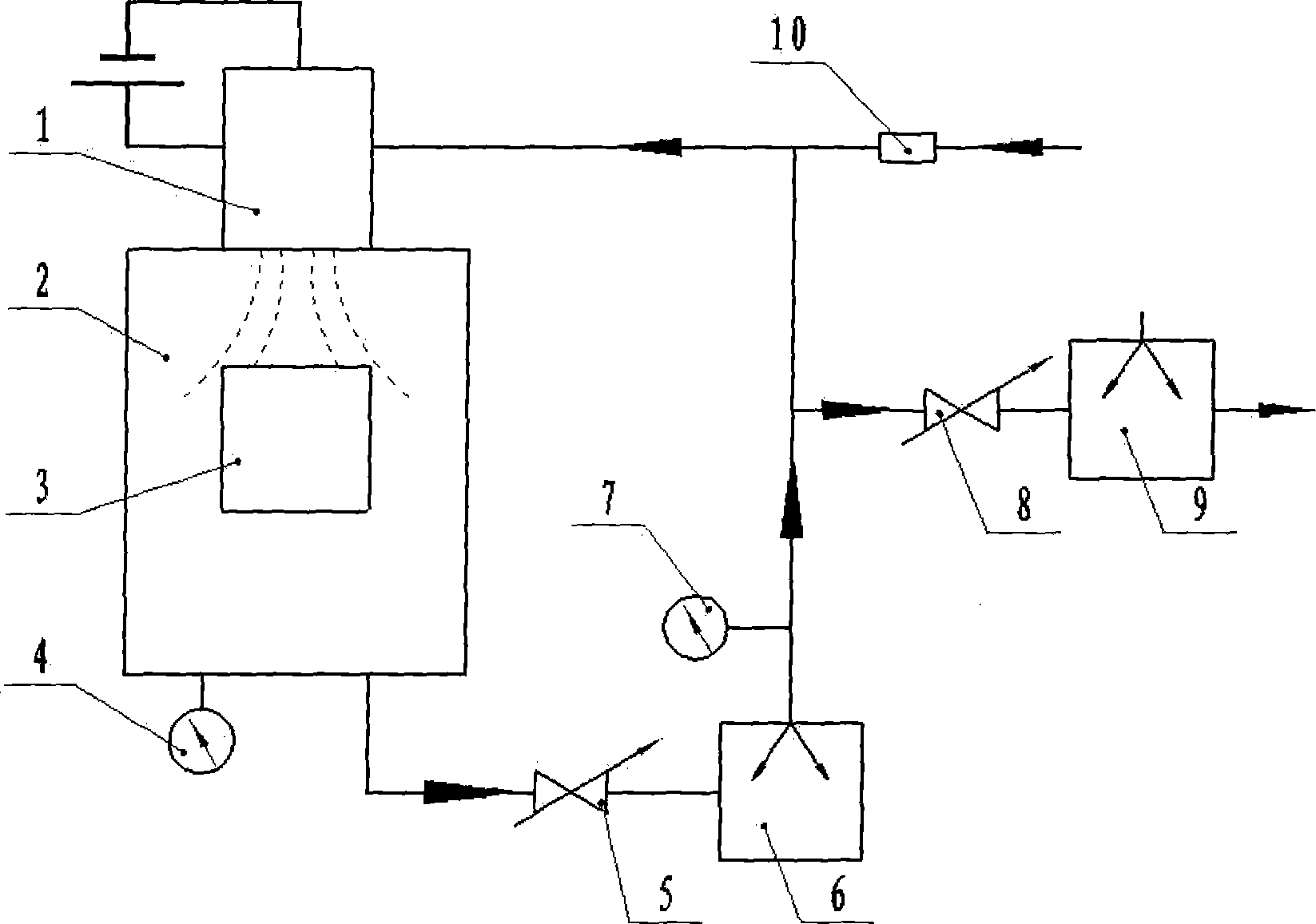

[0012] see figure 1 , the device for chemical vapor deposition of diamond includes a DC arc jet plasma torch 1, a vacuum chamber 2, and a substrate 3, and a gas recycling mechanism is arranged between the vacuum chamber 2 and the DC arc jet plasma torch 1; the vacuum chamber 2 is a closed type structure, and is provided with an outlet connected to the gas recycling mechanism, the gas recycling mechanism is provided with a booster pump 6, and the outlet pipe of the booster pump 6 is connected with the exhaust pipe and the inlet pipe of the DC arc jet plasma torch 1; the gas return The mechanism is provided with a vacuum chamber pressure regulating valve 5, and the exhaust pipe of the booster pump 6 is provided with a booster pump outlet pressure regulating valve 8 and an exhaust pump 9; the vacuum chamber 2 is provided with a vacuum chamber pressure measuring vacuum gauge 4, increasing The outlet pipe of the pressure pump 6 is provided with a vacuum gauge 7 at the outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com