Triangle trim panel installation structure of automobile door

A car door and installation structure technology, applied in the field of car body, can solve problems such as loose assembly, complex molds, and shaking of triangular decorative panels, and achieve the effect of ensuring appearance quality, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

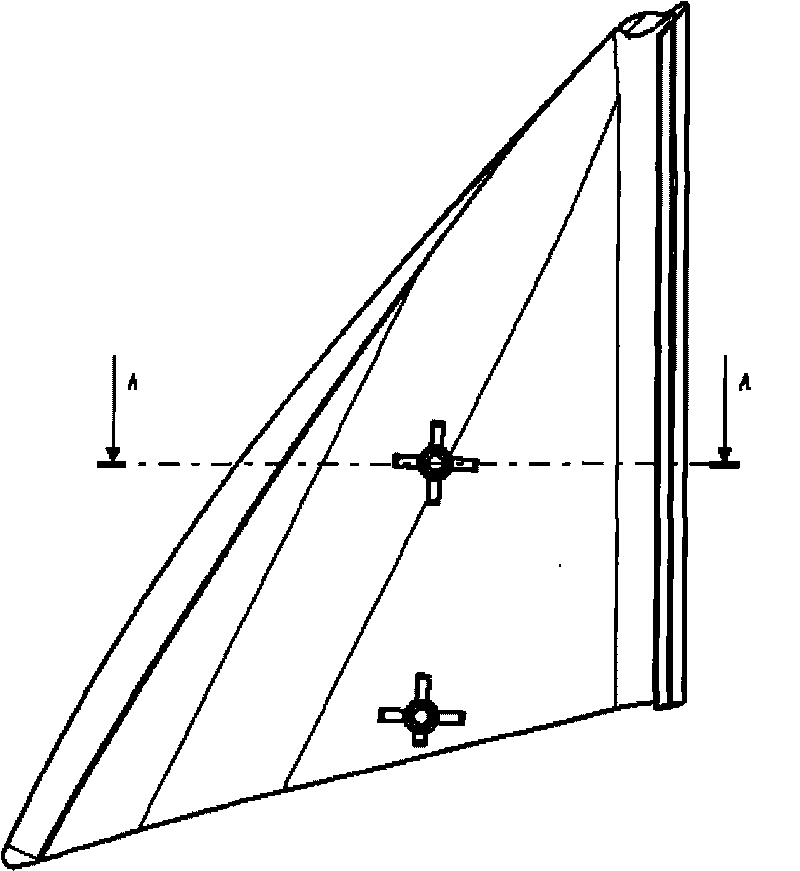

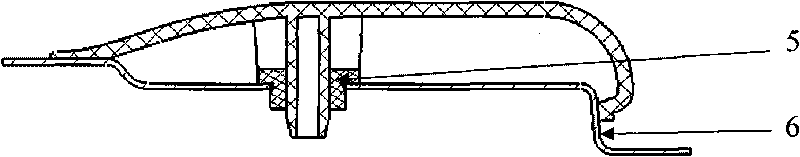

[0015] The installation structure of the triangular decorative panel of the automobile door comprises a door trim panel and a triangular decorative panel. Such as figure 1 and figure 2 As shown, two circular pillars 3 are directly injection molded on the back of the triangular decorative board 1, and there is a table top 2 at the bottom of the pillars 3 to control the step difference between the triangular decorative board and the assembly boundary condition. The end face of the ring 5 fits together to control the assembly distance between the triangular trim panel 1 and the door trim panel 6, and the top of the pillar 3 is tapered to play a guiding role.

[0016] see image 3 , there is a mounting hole on the door inner panel 6 at the position corresponding to the pillar 2 on the back of the triangular decorative panel 1, and a nylon retaining ring 5 is set on the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com