A standard device of a cable fault flash tester

A technology for cable faults and standard devices, which is applied to measurement devices, fault locations, and fault detection by pulse reflection method. Problems, stable and reliable performance, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

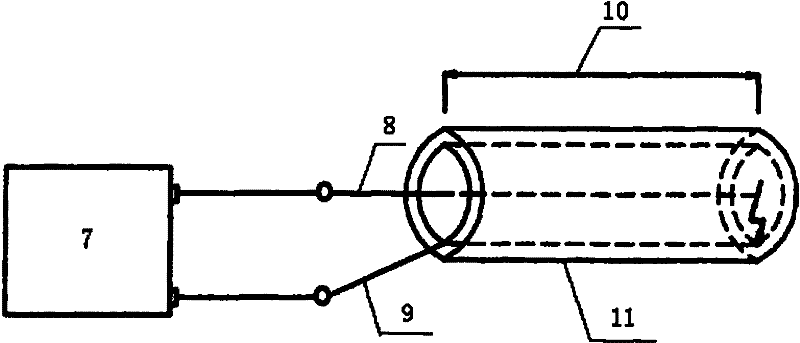

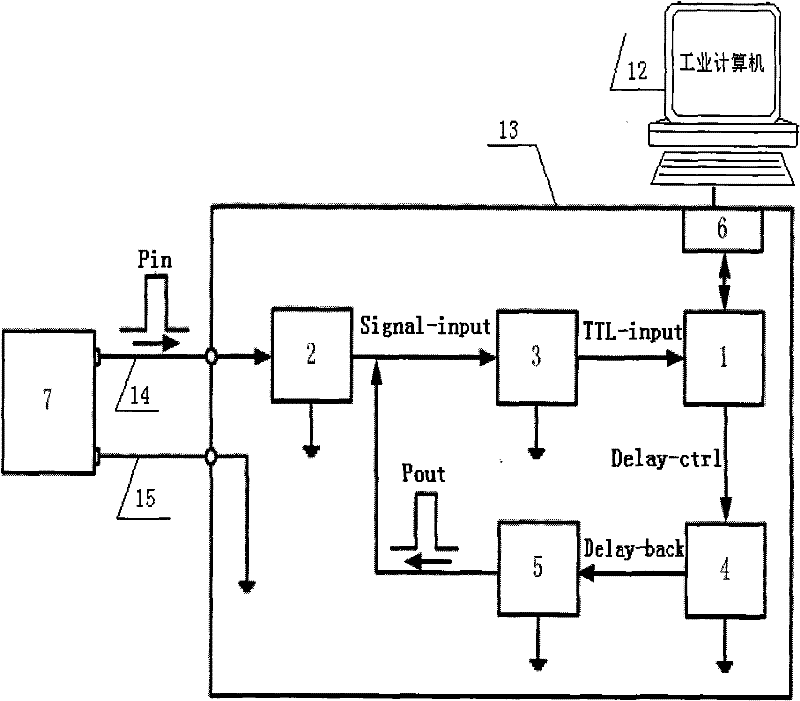

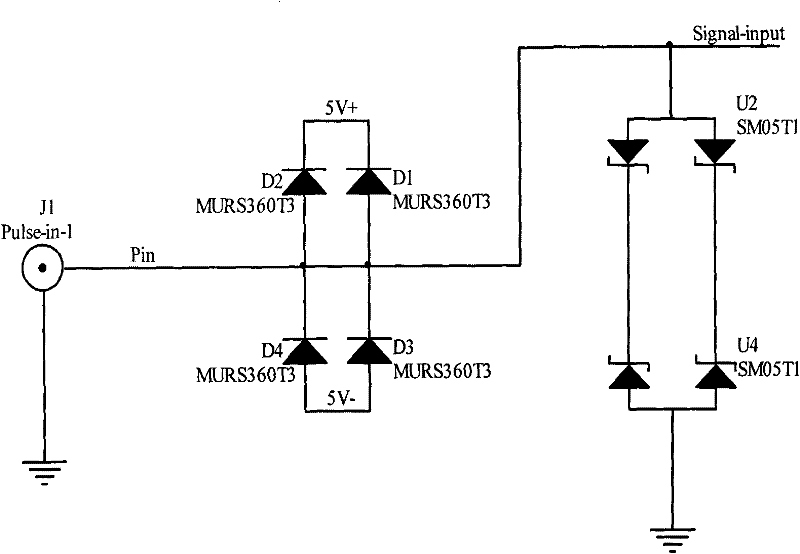

[0025] Marks in the figure: 1-control module, 2-cable core wire multiplexing module, 3-input signal conditioning module, 4-signal delay feedback module, 5-high-speed amplification and drive module, 6-communication interface, 7-by Flash tester for cable fault detection, 8, 14-cable core wire, 9-cable shielding layer, 10-cable fault distance, 11-physical cable, 12-upper computer, 13-lower computer, 15-cable shielding layer, 16- Analog door.

[0026] see figure 1Shown is a schematic diagram of the principle of the calibration method of the traditional cable fault flash detector based on the physical method. In this method, the physical cable 11 is used as a standard instrument, and the length of the physical cable is calibrated with a length measuring instrument in advance. After the calibration, the physical cable is used to calibrate the fault detector of the tested c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com