Orthorhombic double-U-type intelligent visual detection array probe based on alternating current field measurement (ACFM)

A detection probe and intelligent technology, which is applied in the field of intelligent visual detection devices for metal surface defects, can solve problems such as low detection sensitivity and inability to describe three-dimensional shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below through drawings and mathematical analysis.

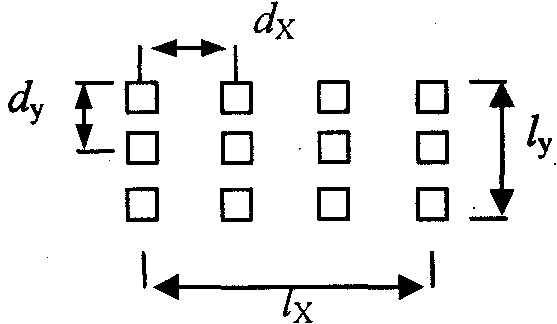

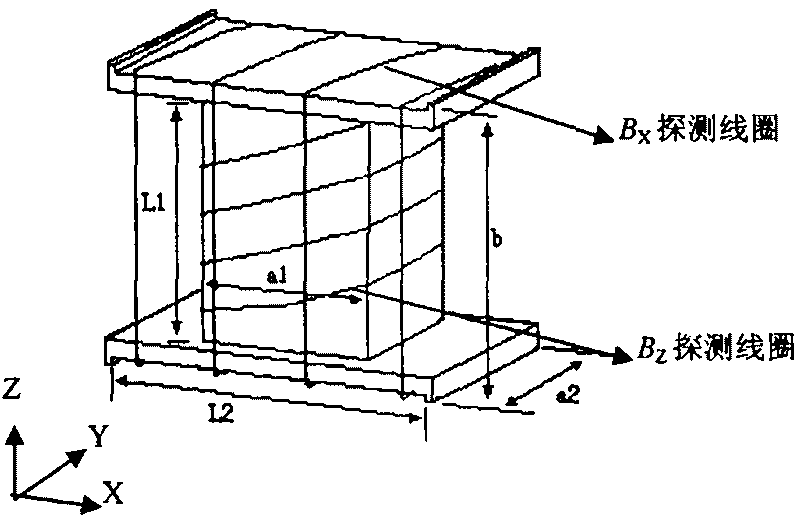

[0012] (1) if figure 1 As shown, sinusoidal excitation signals with the same size and frequency and 90° phase difference are respectively passed through the current-carrying coils of the double U-shaped orthogonal excitation array. According to the law of electromagnetic induction, the induced current generated by the two sets of coils in the workpiece It should also be a sinusoidal signal with the same size, the same frequency as the excitation frequency, and a phase difference of 90°. The induced current generated by the two sets of excitation coils is as follows:

[0013]

[0014]

[0015] In the formula, ω=2πf, f is the coil excitation current frequency, represents the initial phase, I 0 is the amplitude.

[0016] The induced electromagnetic field in the workpiece can be regarded as the superposition of the induced electromagnetic field generated by two sets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com