car engine intake manifold

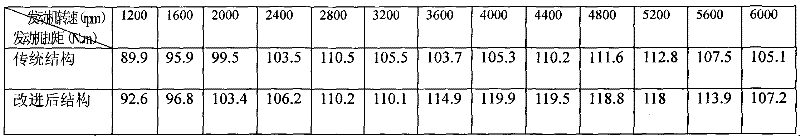

A technology for automobile engines and intake manifolds, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems affecting cylinder charging efficiency, engine vibration and noise, and poor gas flow, so as to improve charging efficiency and reduce Vibration and noise, effect of improving inflation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

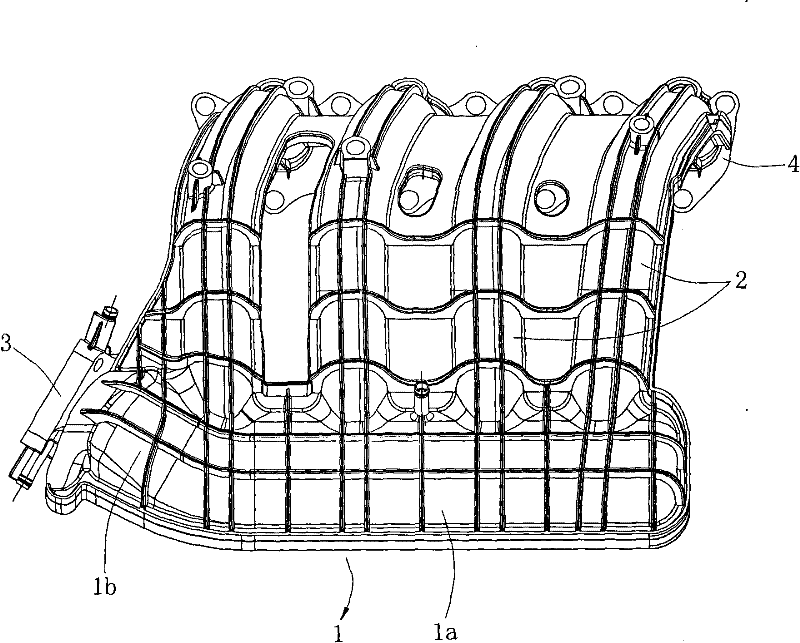

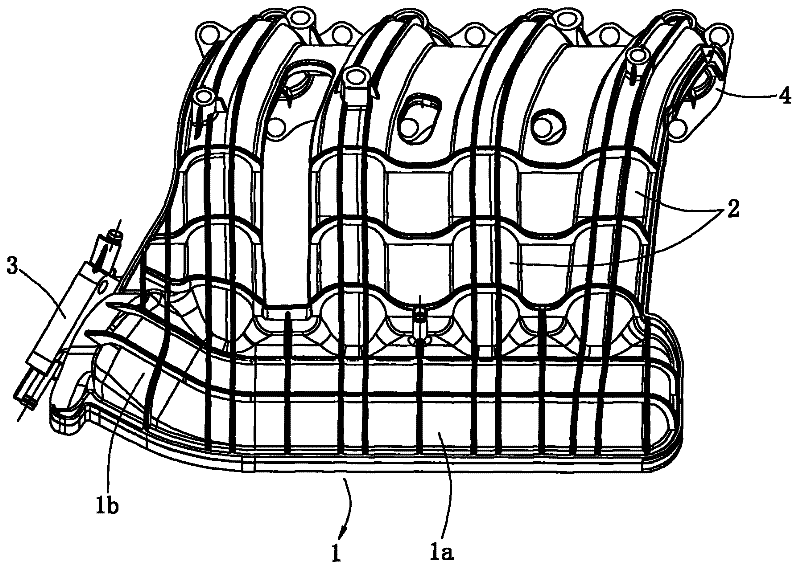

[0014] Such as figure 1 As shown, the present invention consists of a pressure stabilizing chamber 1, an intake elbow 2, a throttle valve mounting flange 3 and a cylinder head mounting flange 4, and each part is made of engineering plastics. The pressure stabilizing chamber 1 is a cylindrical structure with one end open and the other closed, consisting of a straight section 1a and an obliquely upturned intake manifold 1b, the intake manifold 1b is connected to the throttle valve mounting flange 3, and the stabilizing chamber There is an included angle of 145-155° between the axis of the straight section 1a and the axis of the intake manifold 1b, and in this embodiment, the included angle is preferably 150°. There are multiple intake elbows 2 connected side by side between the straight section 1a of the plenum chamber and the cylinder head mounting flange 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com