Wireless sensor network based drilling well site monitoring system

A wireless sensor and monitoring system technology, applied in signal transmission system, borehole/well components, measurement, etc., can solve problems such as complex working environment at the well site, increased project cost, and difficult maintenance of fixed network facilities, so as to improve flexibility and maintenance efficiency, reduced hardware costs, and excellent scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] specific implementation plan

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and a detailed system design scheme and system operation process are proposed, but the protection scope of the present invention is not limited to the following embodiments.

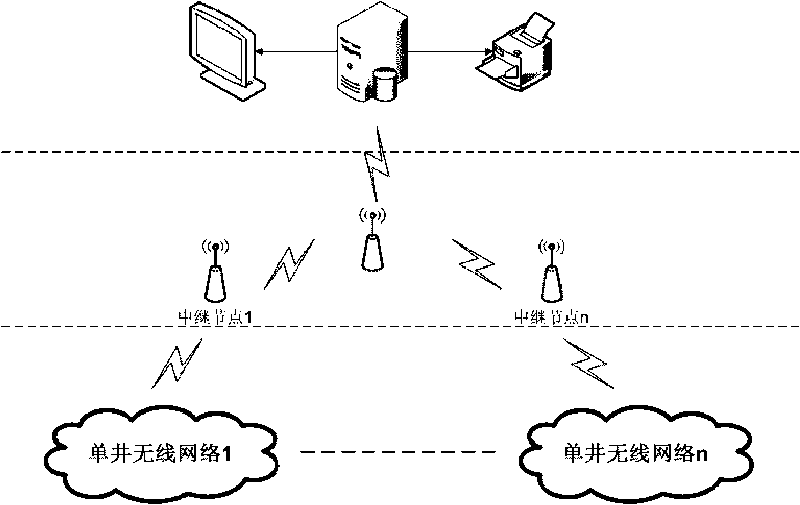

[0036] Such as figure 1 As shown, the system of the present invention consists of three parts, including a single well wireless sensor monitoring network, an interwell wireless relay network, and a central control data analysis system.

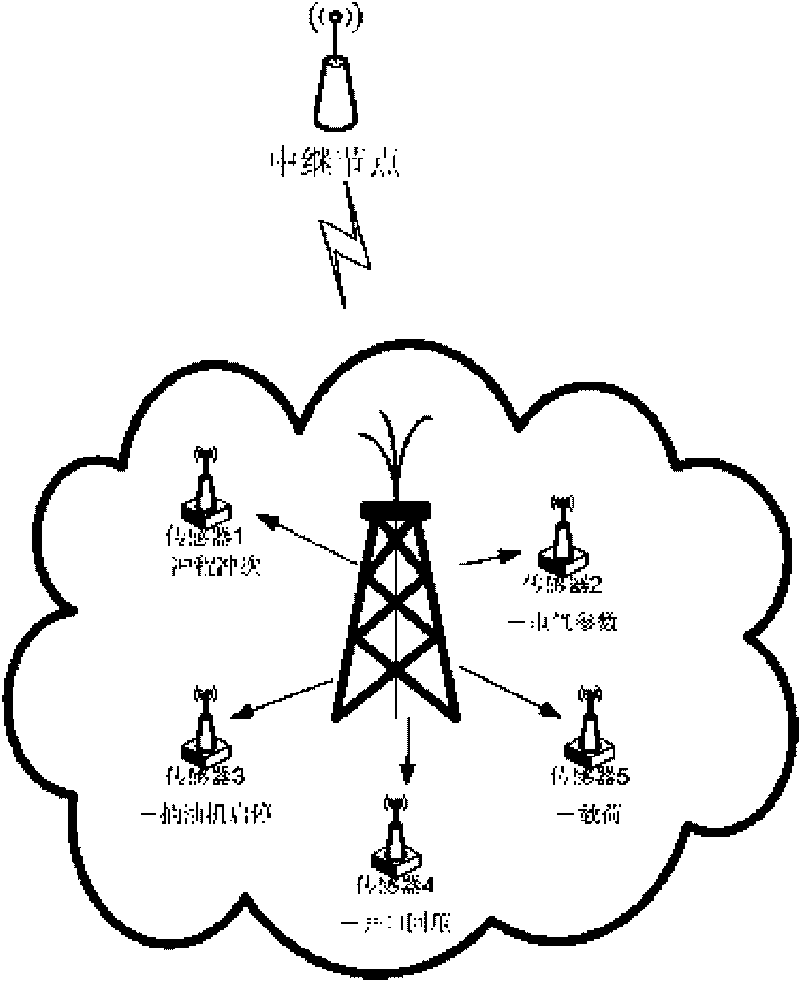

[0037] Such as figure 2 As shown, the single well monitoring network designed in this embodiment includes five sensor nodes, which form a mesh random network structure by themselves through the 2.4GHz industrial control wireless frequency band. The sensor node is installed on the wellhead and pumping u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com