Piston ring inner circle chambering machine

A piston ring and chamfering machine technology, which is applied in milling machine equipment details, metal processing equipment, milling machine equipment, etc., can solve problems such as high labor intensity, low work efficiency, and backward technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

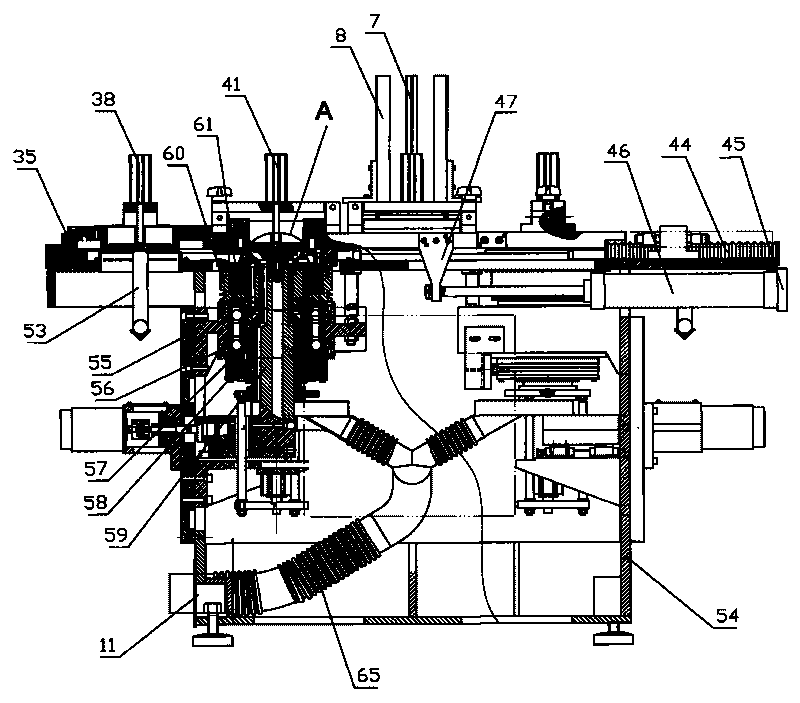

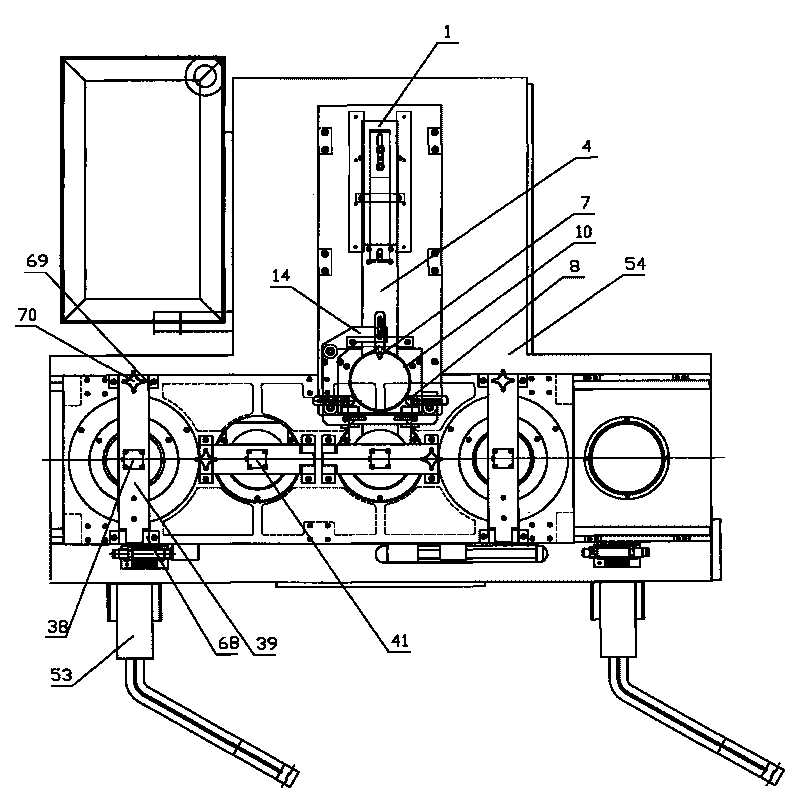

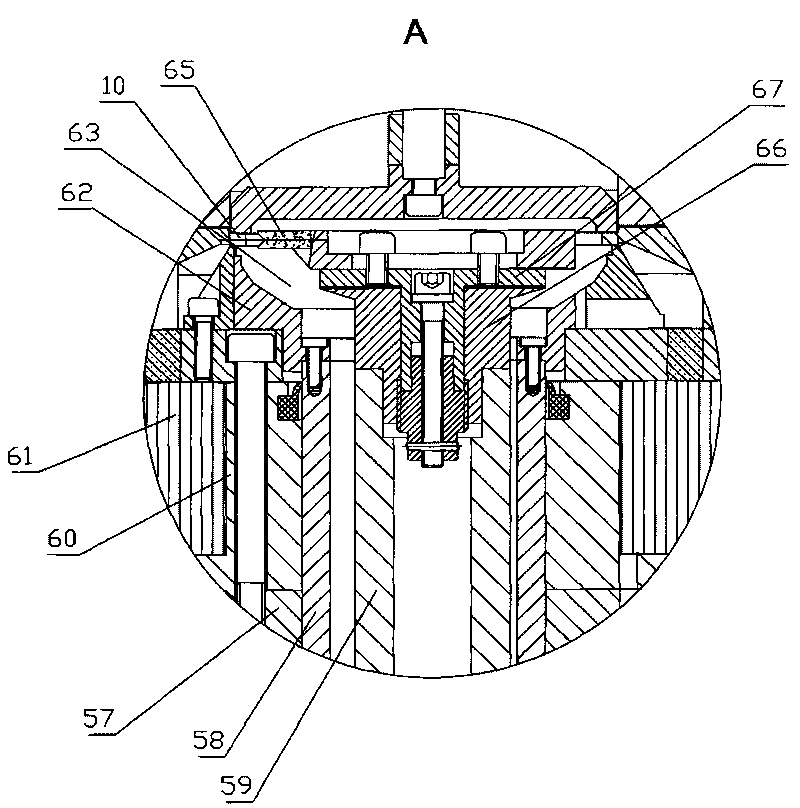

[0022] like figure 1 , 2 , shown in 5, is piston ring inner circle chamfering machine, comprises fuselage 54, and the below of fuselage 54 is symmetrically provided with two ring arrangement mechanisms 53, and each arrangement ring mechanism 53 packs support 17, fixes motor 18 on the support 17, The output shaft of motor 18 connects the ring bar 19, and the other end of the ring bar 19 connects the ring cone 20, and the ring bar 21 is set below the ring bar 19, and the support 17 is fixed on the below of the fuselage 54.

[0023] like figure 1 , 8 , 9, 10, and 11, an automatic feeding mechanism is set above the fuselage 54, the automatic feeding mechanism includes a base plate 3, the rear end of the base plate 3 is provided with a guide groove 9, and the bottom of the base plate 3 is fixed Cylinder 30, cylinder 30 is connected with piston rod support 33, and the upper end of piston rod support 33 is connected the rear end of slide plate 2 by screw 34, and slide plate 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com