Burning tape braider

A technology of taping machine and programmer, applied in static memory, instruments, multiple packages, etc., can solve the problems of increasing the risk of poor contact, prolonged operation time, lengthened IC feet, etc., to achieve cost-effective, convenient and practical , the effect of reducing intermediate operation links and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

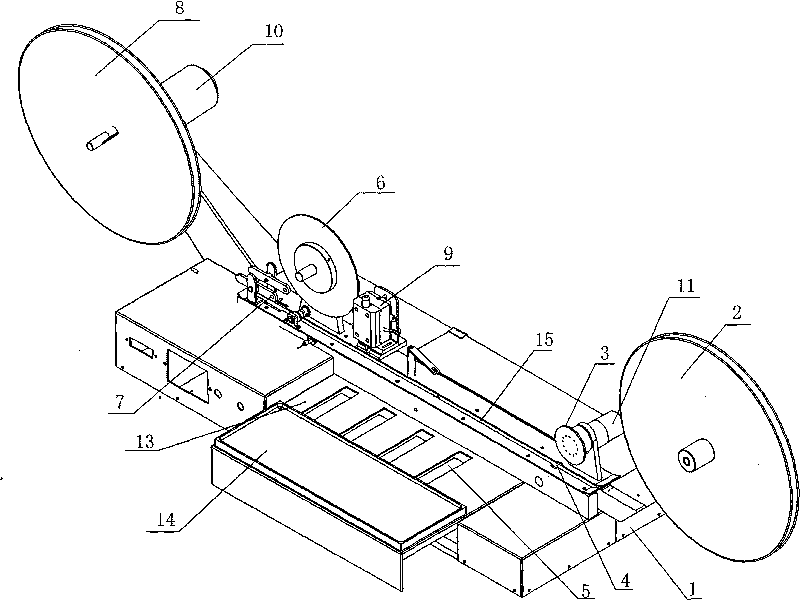

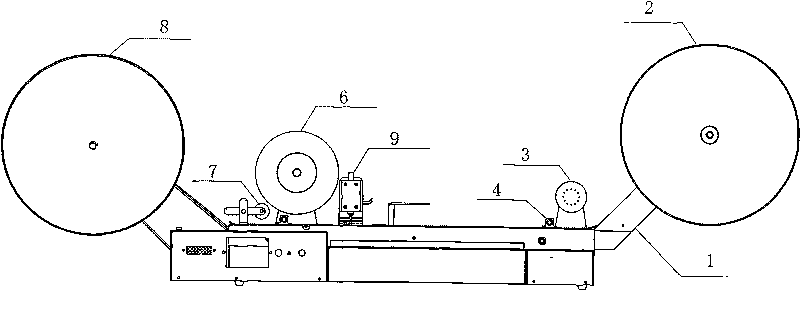

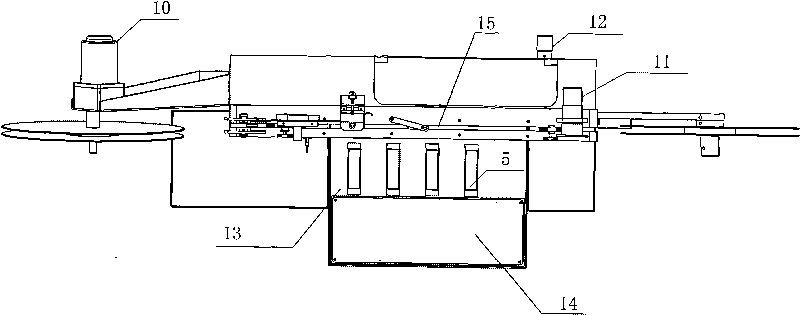

[0016] refer to Figure 1 to Figure 3 , Burn tape machine, comprise support 1, be provided with feed mechanism 2, film closing mechanism 3, carrier tape guide rail 15, film feeding mechanism 6, film pressing mechanism 7 for feeding input in a straight line on described support 1 And the receiving mechanism 8, the side of the support is also provided with a burner 5 for burning IC, and the film receiving mechanism 3 and the receiving mechanism 8 have power sources respectively.

[0017] Further, a film guiding mechanism 4 for guiding is arranged in a straight line between the film winding mechanism 3 and the film feeding mechanism 6 on the support 1 . The film guide mechanism 4 makes the film closing action smoother and enhances the reliability.

[0018] Further, a dotting mechanism 9 is arranged in a straight line between the film winding mechanism 3 and the film feeding mechanism 6 on the support 1 . The dotting mechanism 9 is mainly marked accordingly on the IC.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com