Gravity-flow type efflux technology of condensate of coal gas primary cooler

A primary cooler and condensate technology, which is applied in the auxiliary process field, can solve problems such as fluctuations in circulating spraying volume, inability to discharge condensate, unfavorable stable operation, etc., and achieve the effects of reduced energy consumption, simple structure, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

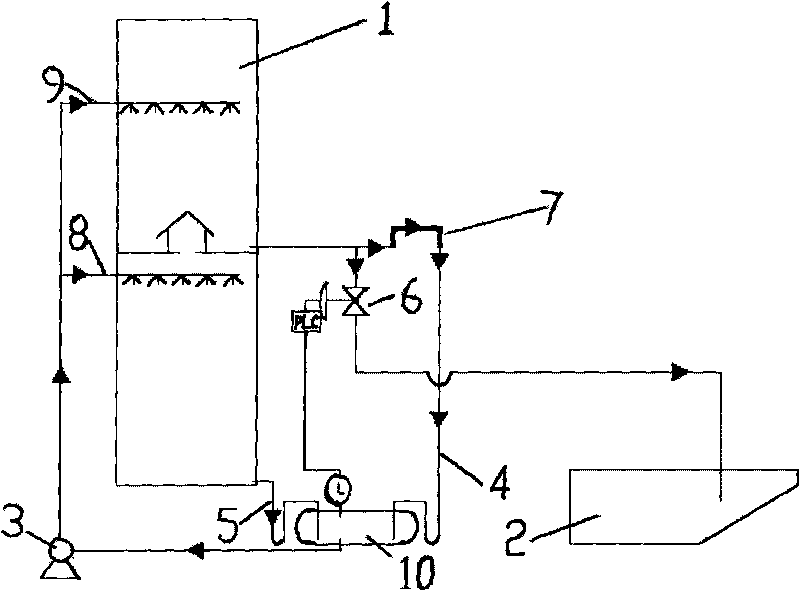

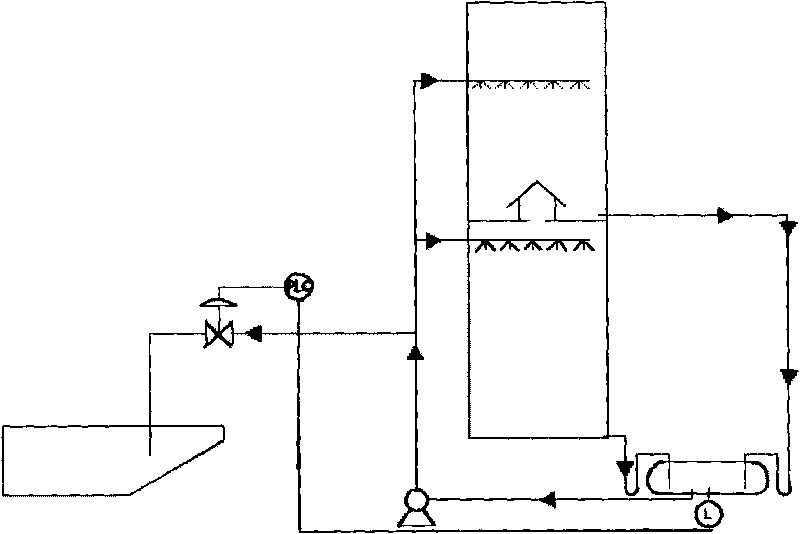

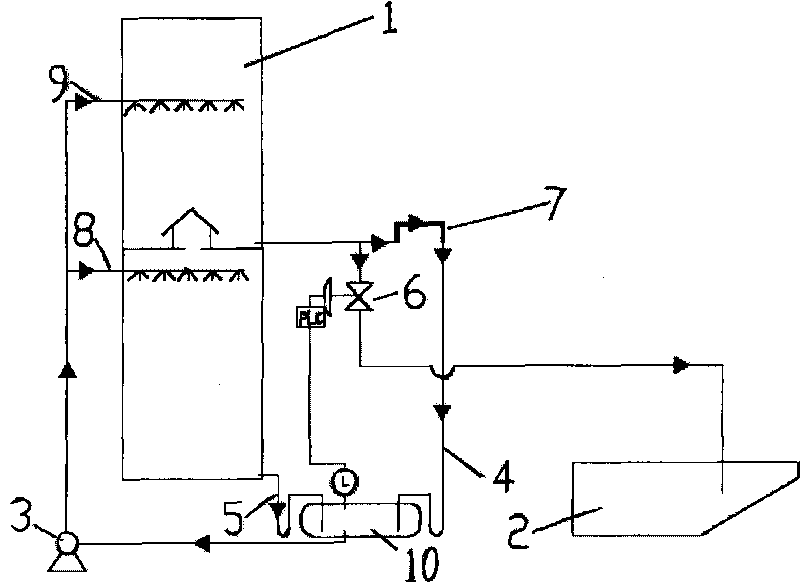

[0014] A self-flowing venting process for the condensate of the primary gas cooler, the process flow is as follows figure 1 As shown, a liquid flow direction selector 7 is provided on the upper oil return pipeline 4, and the two ends of the liquid flow direction selector 7 are respectively connected with the horizontal tube primary cooler 1 and the circulating oil tank 10, and the liquid flow direction selector 7 and the horizontal tube primary cooler The connecting end of the device 1 is connected in parallel with an automatic regulating valve 6 through a pipeline. The two ends of the automatic regulating valve 6 are respectively connected to the horizontal tube primary cooler 1 and the mechanized clarification tank 2; the installation position of the liquid flow selector 7 is higher than that of the upper oil return pipe 4 Horizontal part; the automatic control valve 6 is connected with the PLC program controller, the liquid level gauge and the circulating oil tank 10 by a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com