Biplanar friction integral two freedom degree joint

An integrated, double-plane technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of low positioning accuracy, bulky robotic arms, inconvenient operation, etc., achieve high positioning accuracy, good joint rigidity, and improve positioning accuracy and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

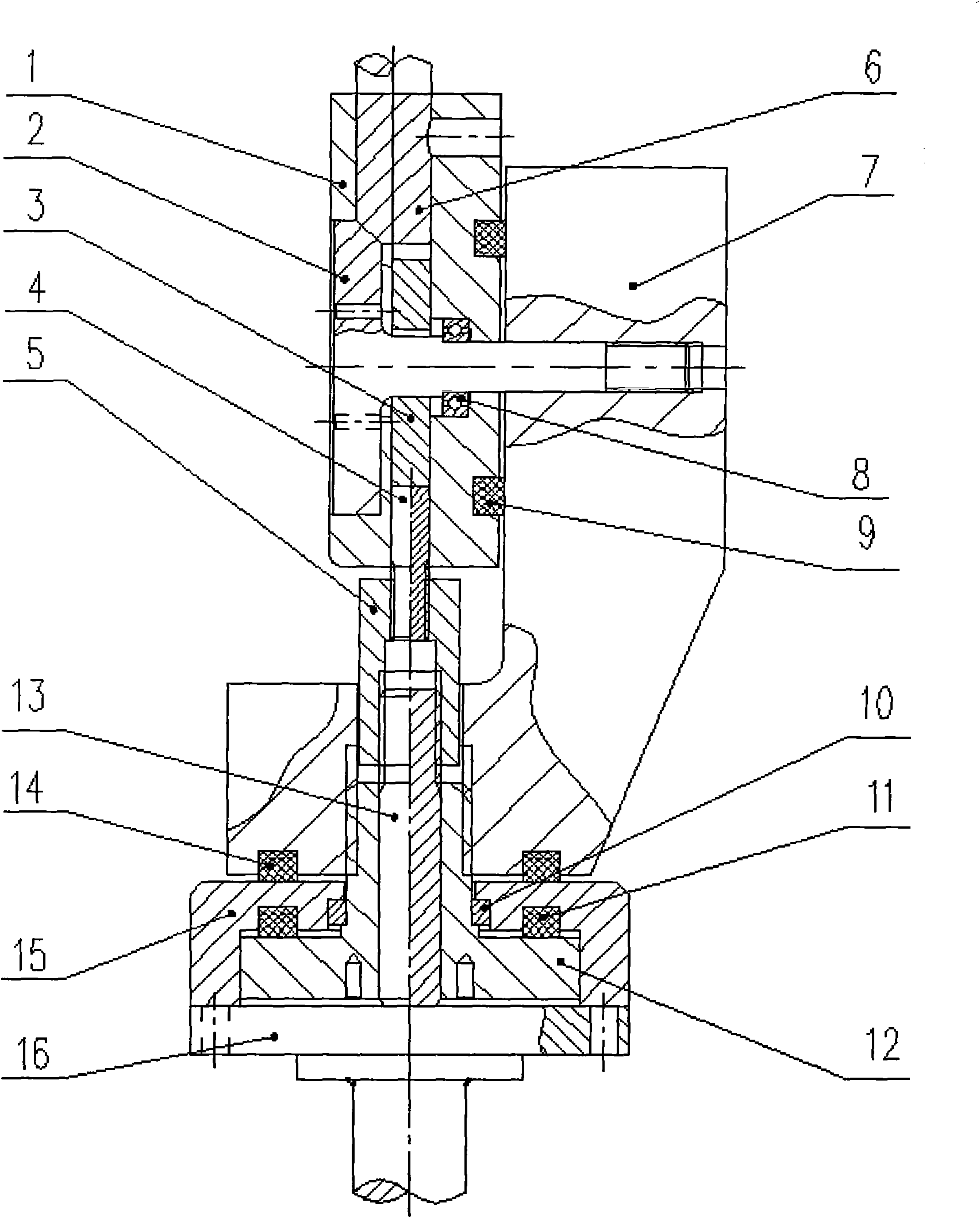

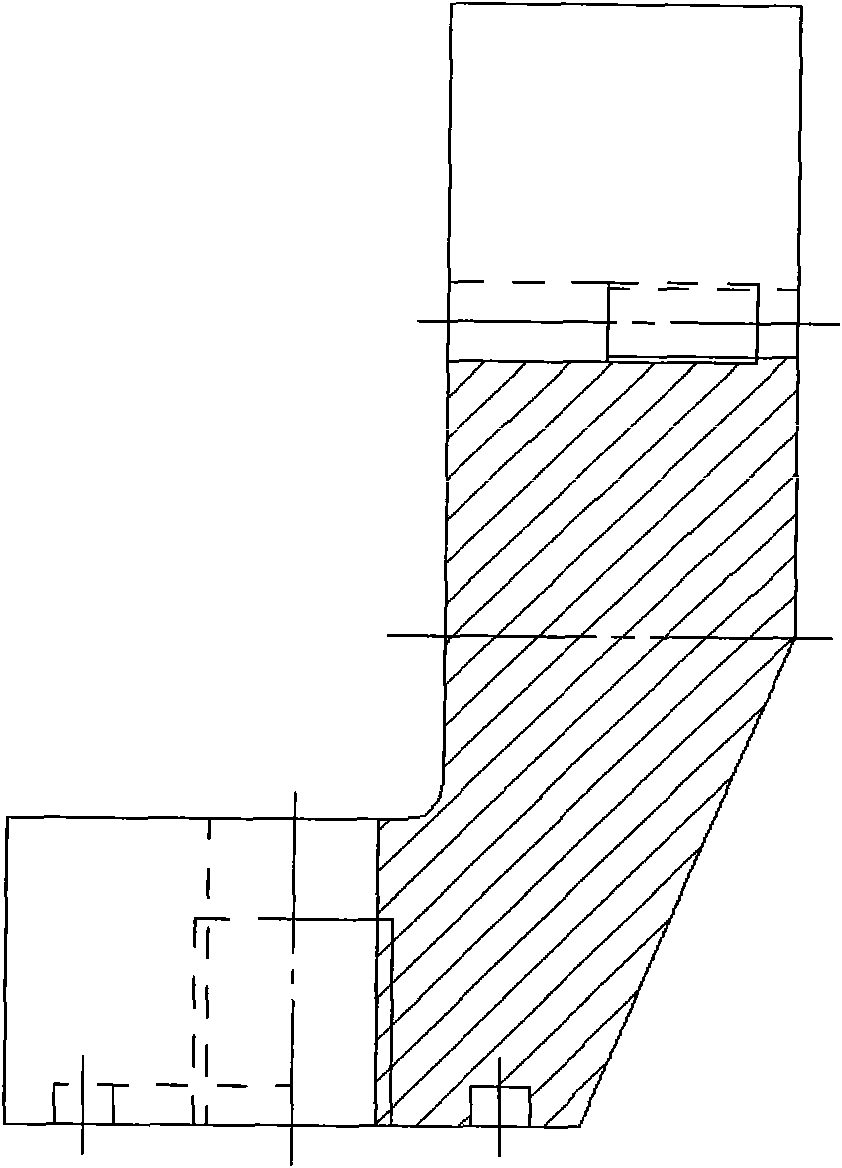

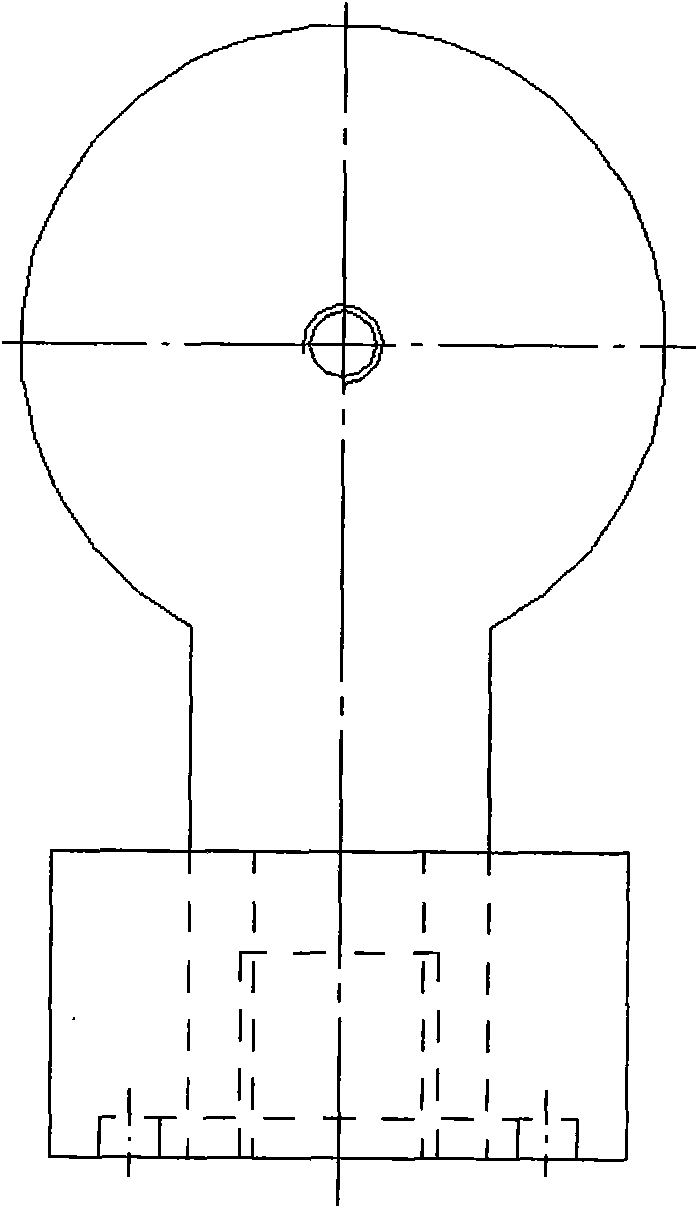

[0023] figure 1 It is a structural schematic diagram of the dual-plane friction integrated 2-DOF joint of the present invention; figure 2 for figure 1 The front view of the joint body in ; image 3 for figure 2 left view of Figure 4 for figure 2 bottom view of Figure 5 for figure 1 The front view of the upper joint T-shaft in ; Image 6 for Figure 5 right view of Figure 7 for figure 1 Front view of the lower joint T-shaft in ; Figure 8 for Figure 7 top view.

[0024] As shown in the figure, the dual-plane friction integrated 2-DOF joint of the present invention includes a joint body 7, a lower joint T-shaped shaft 12 and an upper joint T-shaped shaft 2, wherein the joint body 7 is in an "L" shape, and the upper The upper outer edge of the lower plane of the joint T-shaped shaft 2 is chamfered to form a wedge-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com