Maintenance platform

A technology for repairing platforms and platforms, which is applied in the direction of buildings, building structure support, electrical components, etc. It can solve the problems that the porcelain pillars are not allowed to wear safety belts, the workers fall from high places, and endanger personal safety, etc., and achieve fast, convenient and safe installation. Effect of improvement, good shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

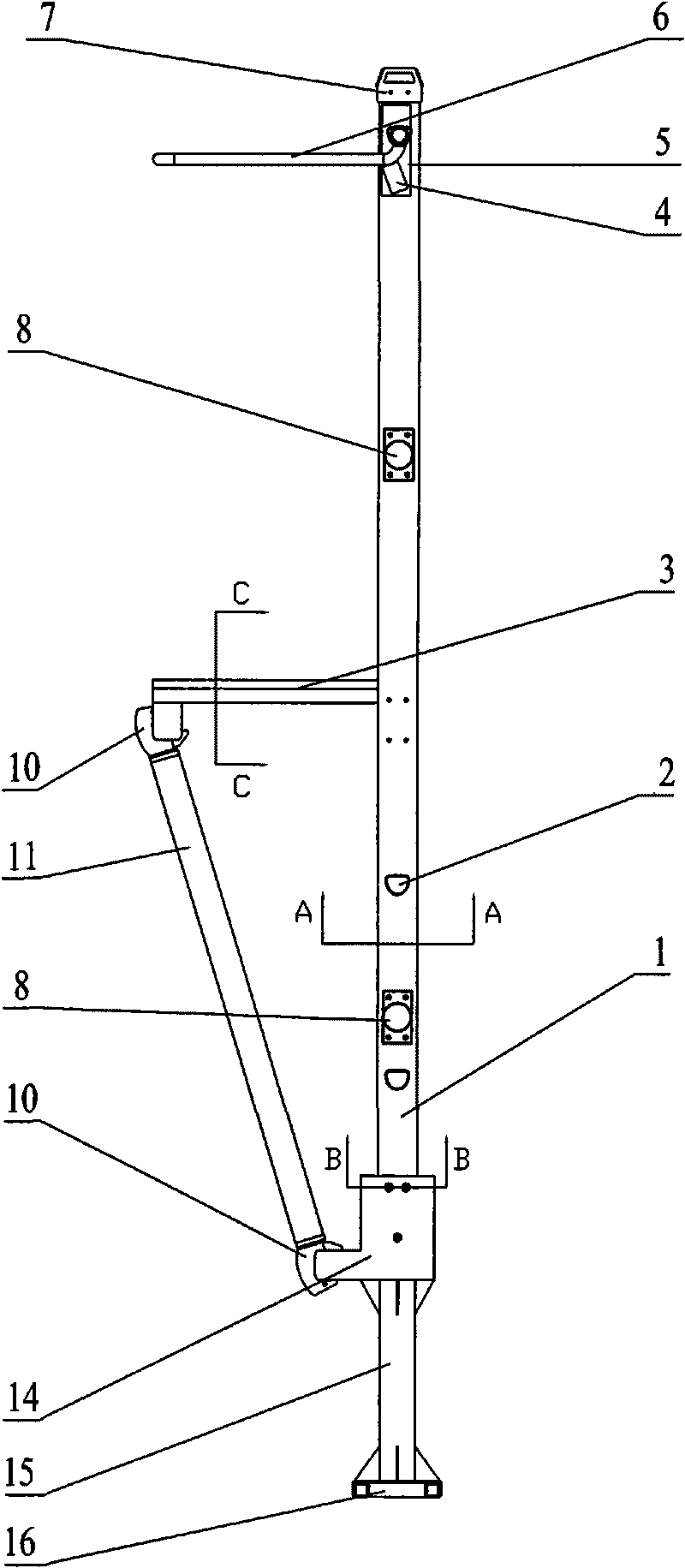

[0023] As shown in the figure, the present invention mainly consists of an insulating straight rod 1, a pedal rod 2, a working platform 3, a fixed square pipe 4, a positioning slot 5, a rotating fence 6, a rubber sleeve 7, a platform support rod seat 8, and a platform support rod. 11. The fixing frame 12 and the locking assembly are composed. Among them, the locking assembly is mainly composed of a locking platen 19, screws 18 and locking bolts 20; the fixing frame 12 is composed of an upper ladder fixing seat 14, a middle round pipe 15 and a lower maintenance platform seat 16, and welding between them Fixed, one-piece structure.

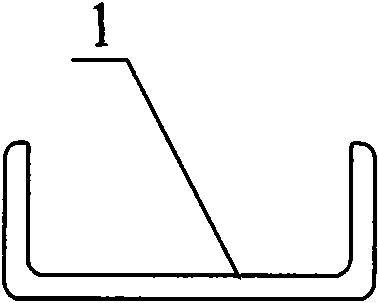

[0024] Such as Figure 1 to Figure 6 As shown, the insulating straight rod 1 has a groove-shaped structure, and there are two in total. The stepping rod 2 is riveted between the two insulating straight rods 1. The upper end is cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com