Method for embedding wax tissue chip

A tissue chip and paraffin technology, applied in the field of paraffin tissue chip embedding, can solve the problems of limited aperture, limited shape, and inability to sample at any time, and achieve the effect of promoting promotion and sufficient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

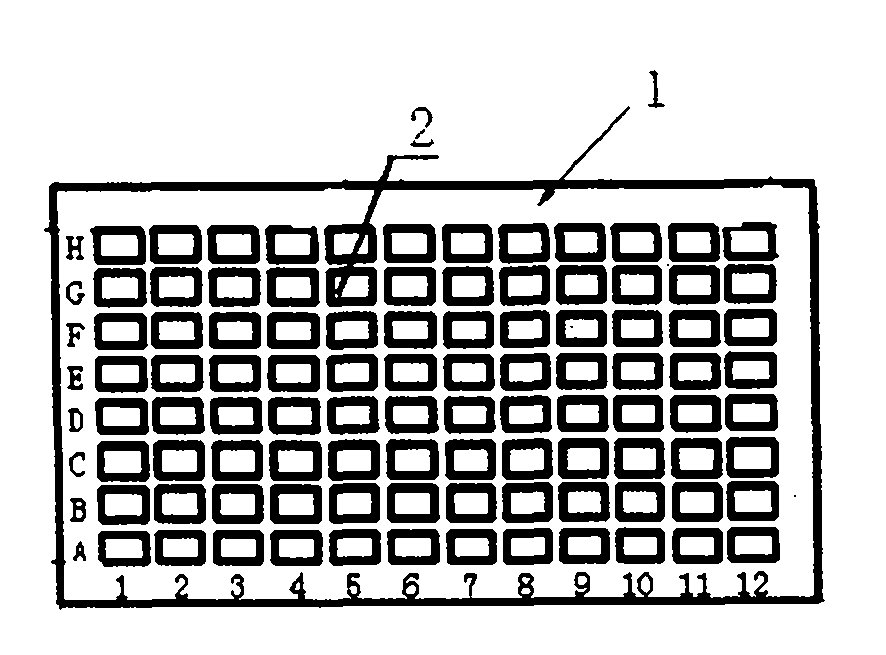

[0026] 1. Preparation of tissue chip memory board:

[0027] Such as figure 1 As shown, it is a schematic diagram of a tissue chip storage board. On a transparent hard plastic board 1 with a thickness of 6 mm to 10 mm, within a range of 50 mm in length and 25 mm in width, engrave length b: 1 mm to 5 mm, width a: 1 mm to 5 mm, and depth d : 2-3mm square or rectangular grooves constitute the first groove array 2, and a range of 5mm-10mm is reserved around the transparent hard plastic plate 1 for marking the number of rows (such as A, B, C, D... ) and number of rows (such as 1, 2, 3, 4...), which is convenient for organizing chip positioning. Or grooves with different lengths and widths are arranged in a separate row for combination. Used to store tissue chips during embedding.

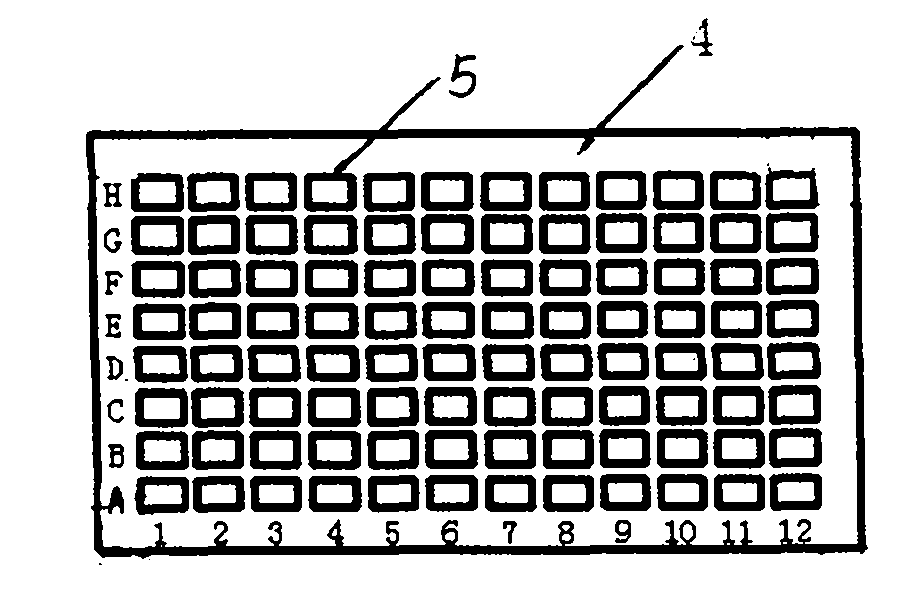

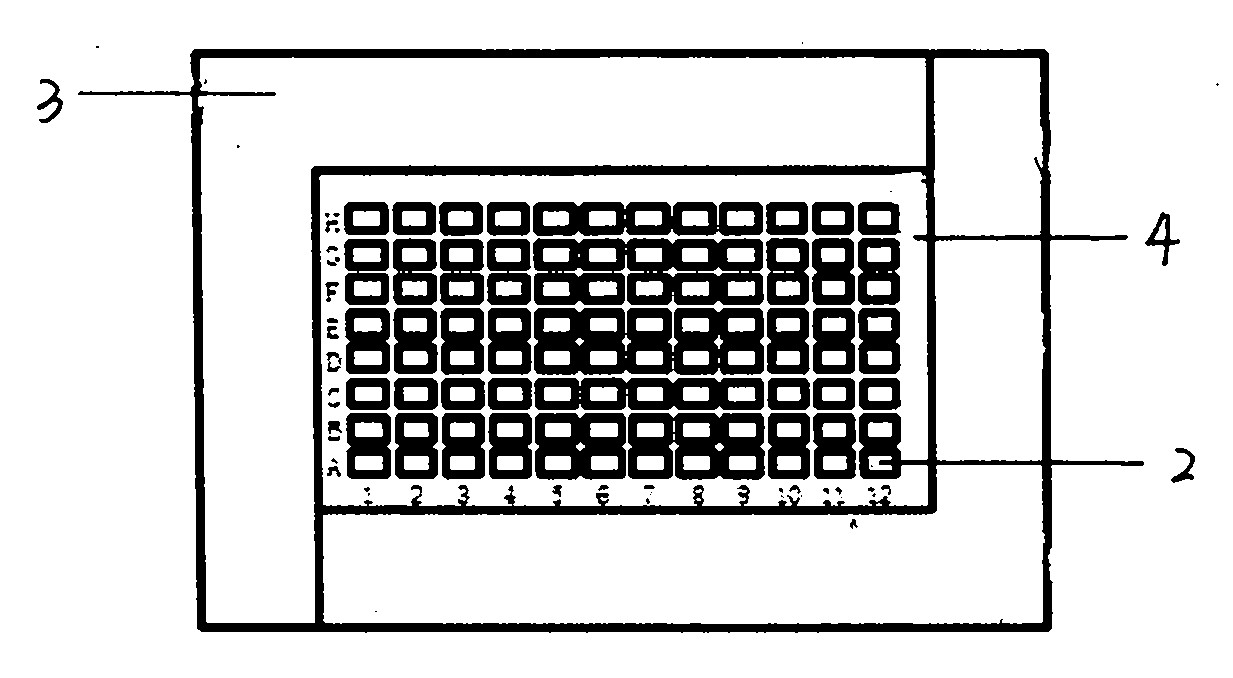

[0028] Preparation of tissue chip embedding plate:

[0029] Such as figure 2 As shown, it is a schematic diagram of a tissue chip embedding plate. The heat-resistant plate 4 can be made of plastic (...

Embodiment 2

[0036] Similar to Example 1, the difference is that in the step of embedding the tissue chip with the tissue chip embedding plate, put the paraffin into the paraffin pot, heat it to 70°C with an electric furnace to melt the paraffin; add the melted paraffin into the wax model along one end of the wax model until it is filled with the wax model, let stand at 25°C for 10 minutes to allow the paraffin to polymerize, and then remove the wax model; separate the tissue chip embedding plate from the paraffin to obtain a wax block containing the tissue chip, and place the tissue chip side of the wax block toward Place it on the ironing table until the bottom surface is flat, and slice along the direction parallel to the flat surface of the tissue chip.

Embodiment 3

[0038] Similar to Example 1, the difference is that in the step of embedding the tissue chip with the tissue chip embedding plate, put the paraffin into the paraffin pot, and heat it to 65°C with an electric furnace to melt the paraffin; add the melted paraffin into the wax model along one end of the wax model until it is filled with the wax model, let stand at 20°C for 20 minutes to allow the paraffin to polymerize, and then remove the wax model; separate the tissue chip embedding plate from the paraffin to obtain a wax block containing the tissue chip, and place the tissue chip side of the wax block toward Place it on the ironing table until the bottom surface is flat, and slice along the direction parallel to the flat surface of the tissue chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com