Temperature-sensing synchronous roasting machine

A frying machine and baking pan technology, which is applied in the field of frying machines, can solve problems such as unstable fuse temperature, affecting service life, fuse blown, etc., and achieve stable and controllable working temperature, guarantee of personal safety, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

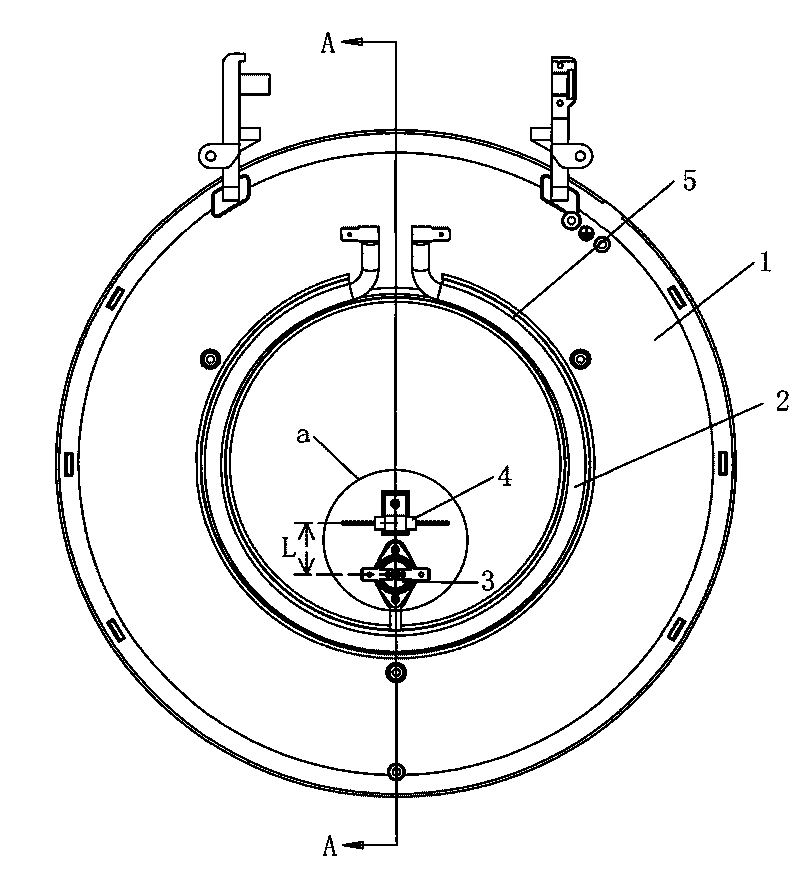

[0025] The structure diagram of the present invention is as figure 1 , 2 , 3, including the electric heating tube 2 for heating the grill pan 1 and the food on the front of the grill pan 1, the thermostat 3 for measuring the temperature of the grill pan 1 and the fuse 4 for electric safety protection, the electric heating tube 2, the temperature control Both the controller 3 and the fuse 4 are installed on the baking pan 1, wherein the distance L between the temperature sensing points of the thermostat 3 and the fuse 4 on the baking pan 1 is not greater than 35 mm.

[0026] In order to increase the temperature-sensing area of the fuse 4 and make its temperature sensing more accurate, the above-mentioned baking pan 1 is provided with a pit 11 , and the fuse 4 is placed in the pit 11 provided on the baking pan 1 .

[0027] The above-mentioned electric heating tube 2 is placed on the back of the baking pan 1 and installed in the groove 5 provided on the back of the baking pan...

Embodiment 2

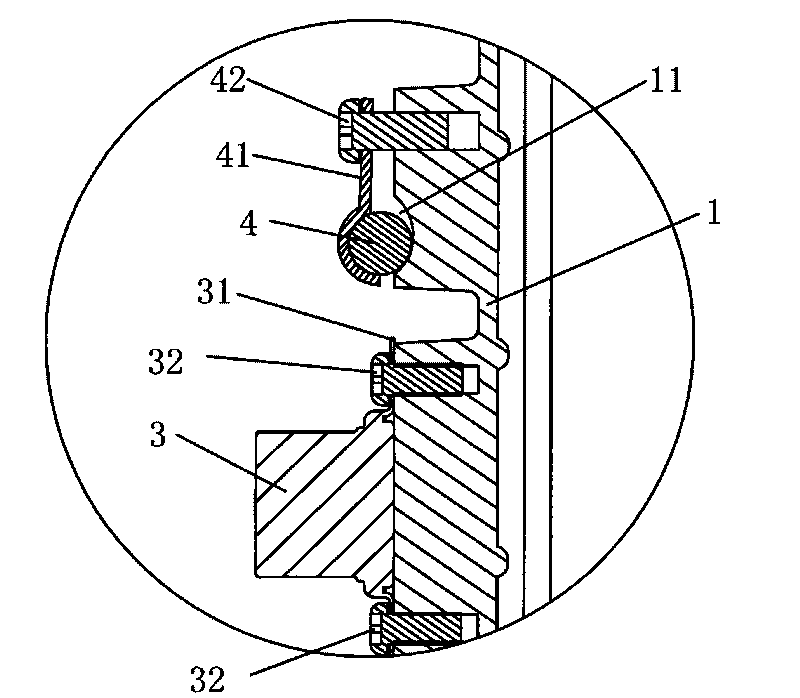

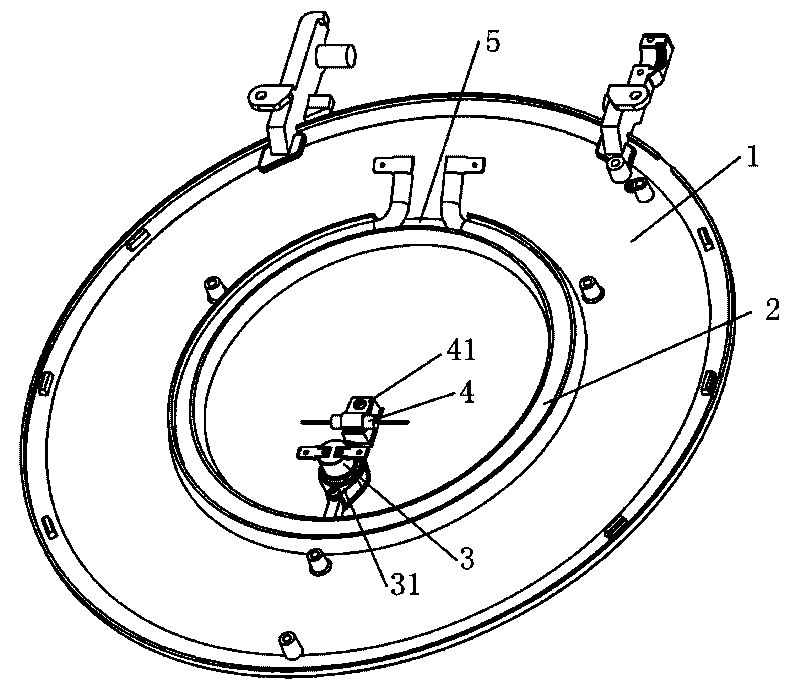

[0033] The structure diagram of the present invention is as Figure 4 , 5 , 6, its structure is the same as that of Embodiment 1, the difference is that the lower end of the above-mentioned thermostat 3 extends outwards with a fixed thermostat bracket 31, and the thermostat 3 passes through the connection of the thermostat bracket 31 The piece 32 is fixed on the baking pan 1 , and the fuse 4 is fixed on the thermostat bracket 31 through the connecting piece 42 passing through the fuse bracket 41 . In this embodiment, the connecting piece 32 passing through the thermostat bracket 31 and the connecting piece 42 passing through the fuse bracket 41 are screws.

[0034] The working principle of the present invention is as follows: the thermostat 3 senses the temperature of the baking tray 1 through the thermostat bracket 31, and the distance L between the temperature sensing point of the thermostat 3 and the temperature sensing point of the fuse 4 on the grilling tray 1 is constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com