Segmenting type sugar cane combine harvester

A combine harvester and section-cutting technology, which is applied in the direction of harvesters, cutters, agricultural machinery lifting devices, etc., can solve the problems of reducing production, soil compaction, increasing transportation costs, etc., and achieve the effect of reducing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

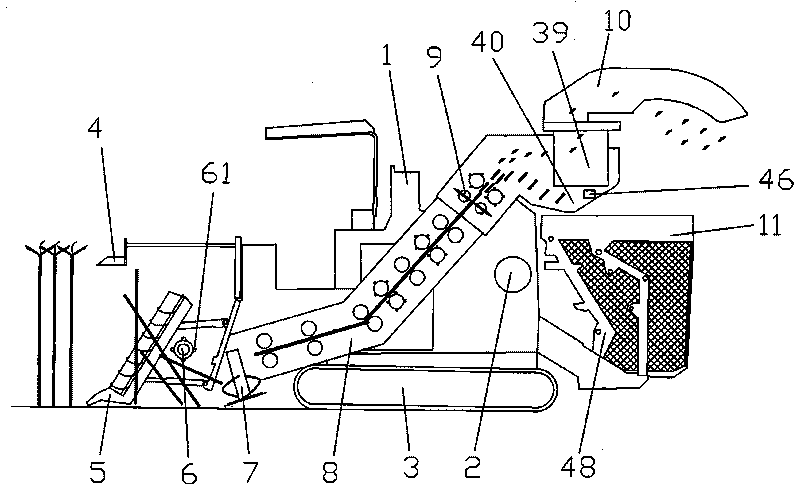

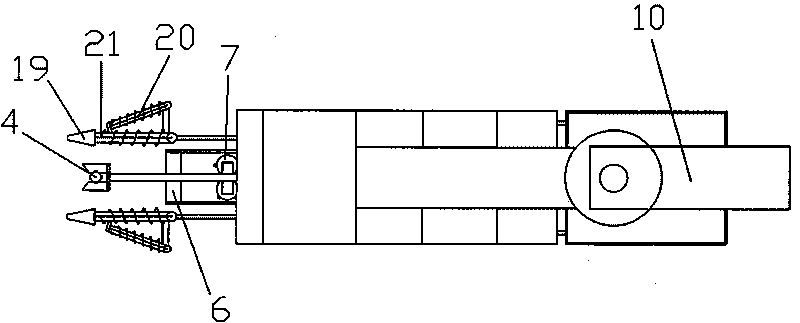

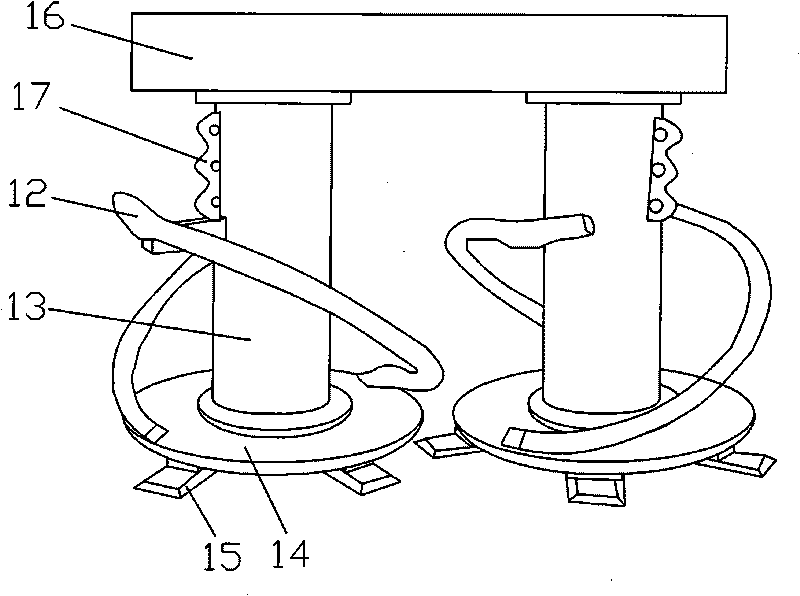

[0034] Such as figure 1 , figure 2 As shown, a section-cutting sugarcane combine harvester includes a frame 1, an engine 2, a crawler-type walking mechanism 3, a hydraulic power and control system, a tip cutting device 4, a cane holding device 5, a cane pressing and carding drum 6, a cutting Device 7, conveying leaf stripping device 8, section cutting device 9, miscellaneous removal device 10 and assembly device 11, tip cutting device 4 is installed on the front top of harvester, and cane-holding device 5 is installed on the front end of harvester, in the harvester Behind the cane-supporting device 5 at the abdomen, the cane-pressing and carding cylinder 6 and the cutting device 7 are successively installed, and the conveying and stripping device 8 is obliquely installed in the middle of the harvester, and its conveying inlet is set corresponding to the upper part of the cutting device 7, and the section-cutting device 9 is installed In the conveying stripping device 8, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com