Drip sheet

A technology of dripping and absorbing sheet, which is applied in food preservation, flexible covering, container and other directions, can solve the problems of reducing the volume of absorbing sheet and absorbing dripping liquid, etc., and achieves the effect of improving prevention effect and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

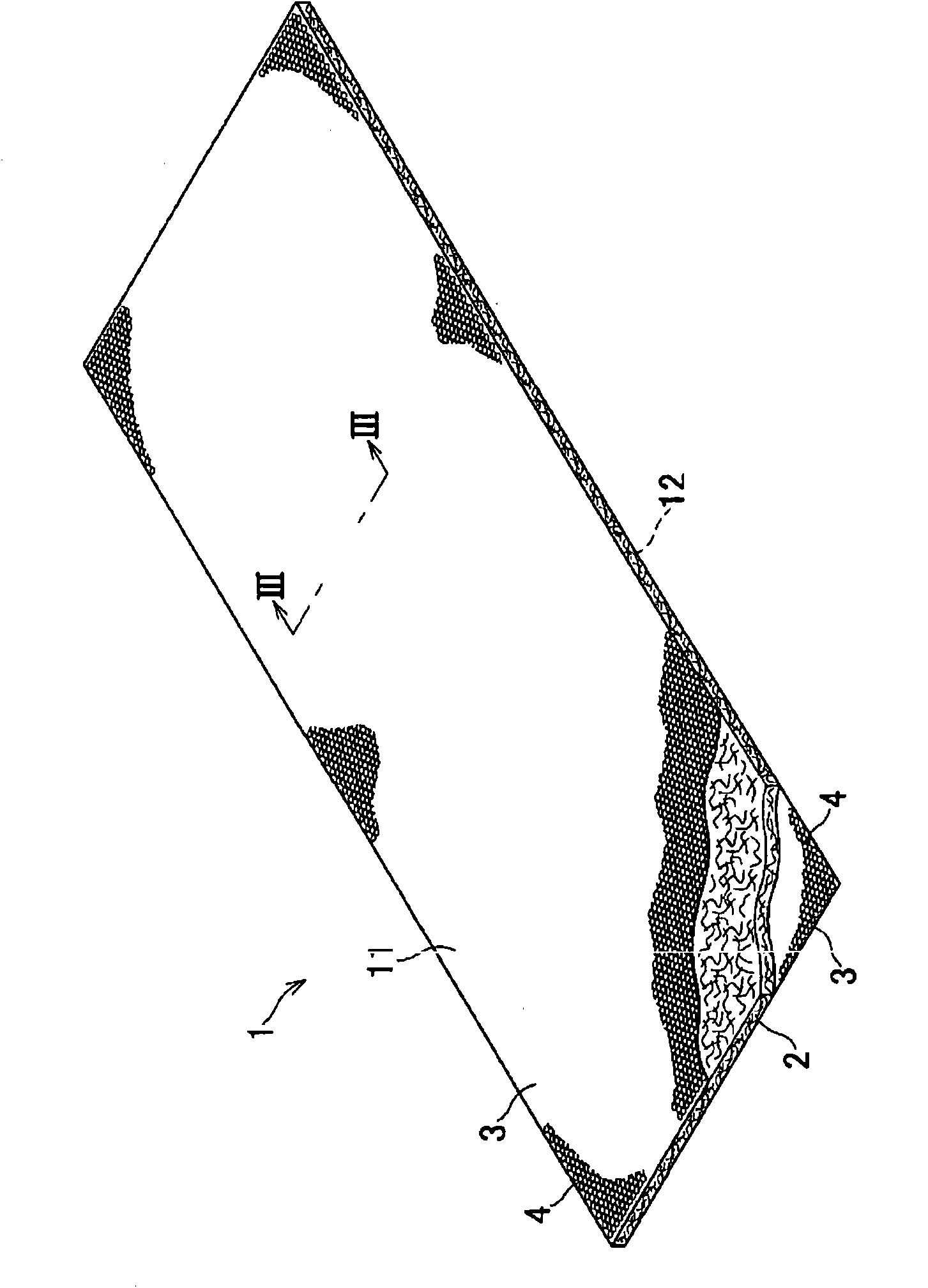

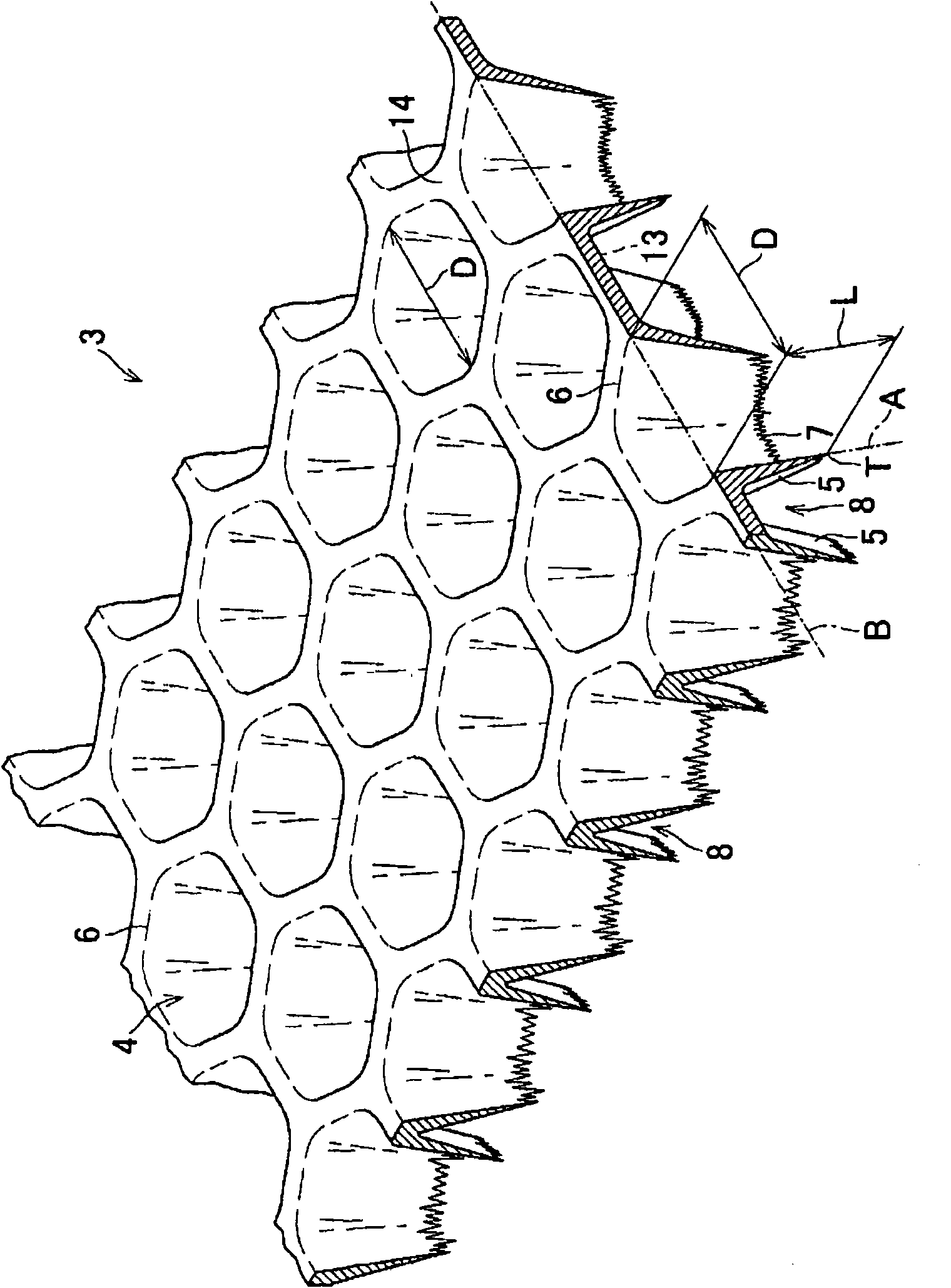

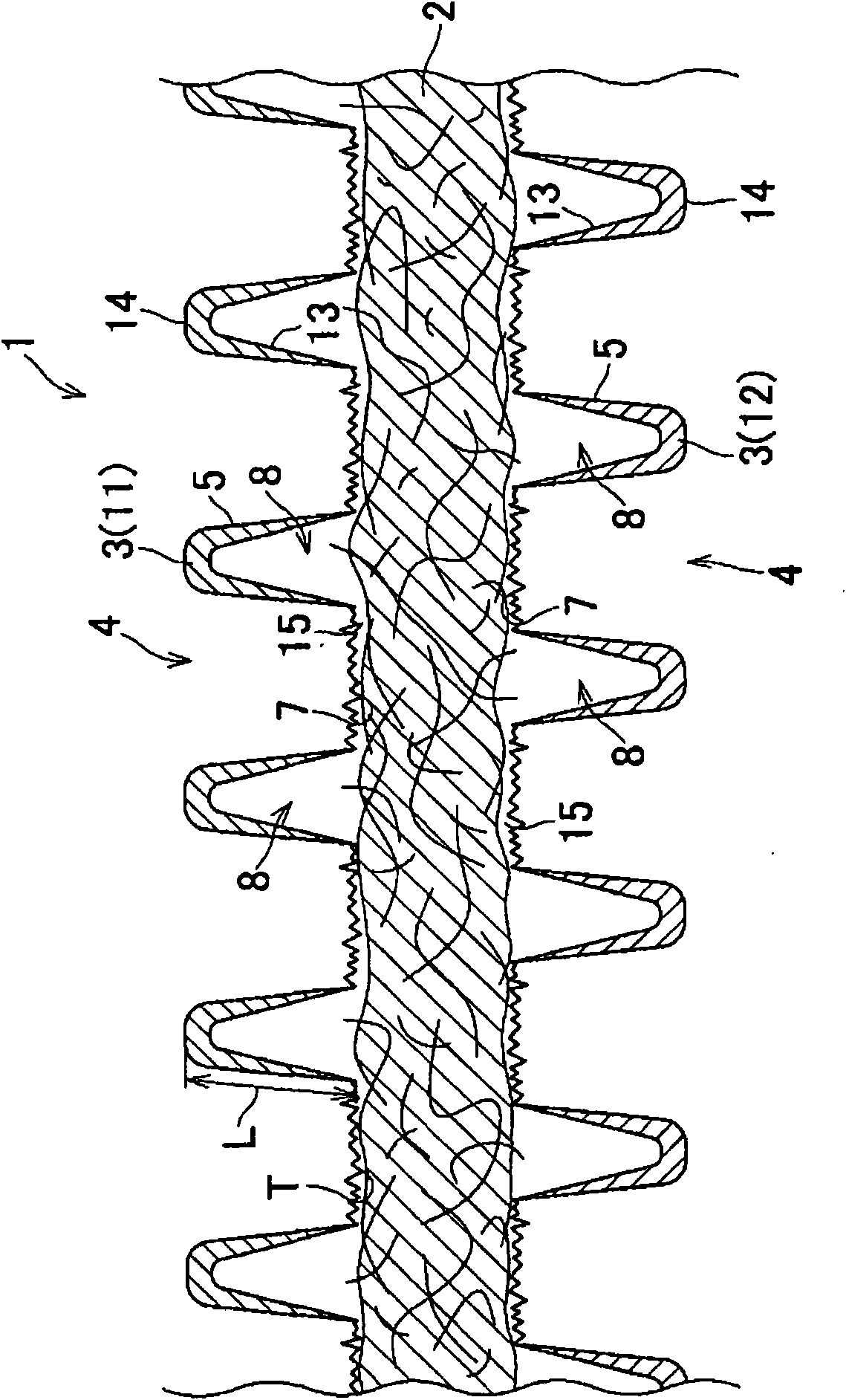

[0040] The drip sheet 1 according to the present invention will be described below with reference to the accompanying drawings. figure 1 It is a perspective view showing a part of the drip sheet 1 cut away, figure 2 It is an enlarged perspective view of a part of the thermoplastic sheet 3 bonded to the drip sheet 1, image 3 is a schematic representation along the figure 1 The illustration of the end surface when the drip sheet 1 is cut by line III-III.

[0041] Such as figure 1 As shown, the drip sheet 1 is joined with a thermoplastic sheet 3 of the same shape and size on the upper surface 11 and the lower surface 12 of the absorbent sheet 2, and food (not shown) is placed on the upper surface of the absorbent sheet 2 11 sides. In addition, on each thermoplastic sheet 3 , a plurality of openings 4 of approximately the same shape are alternately arranged at intervals. In the following description, the thermoplastic sheet 3 joined to the upper surface 11 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com