Dual clutch arrangement having a piston guide element

A technology of clutches and friction clutches, applied in the field of clutch systems, which can solve the problems of large inertia of external plate brackets and large structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

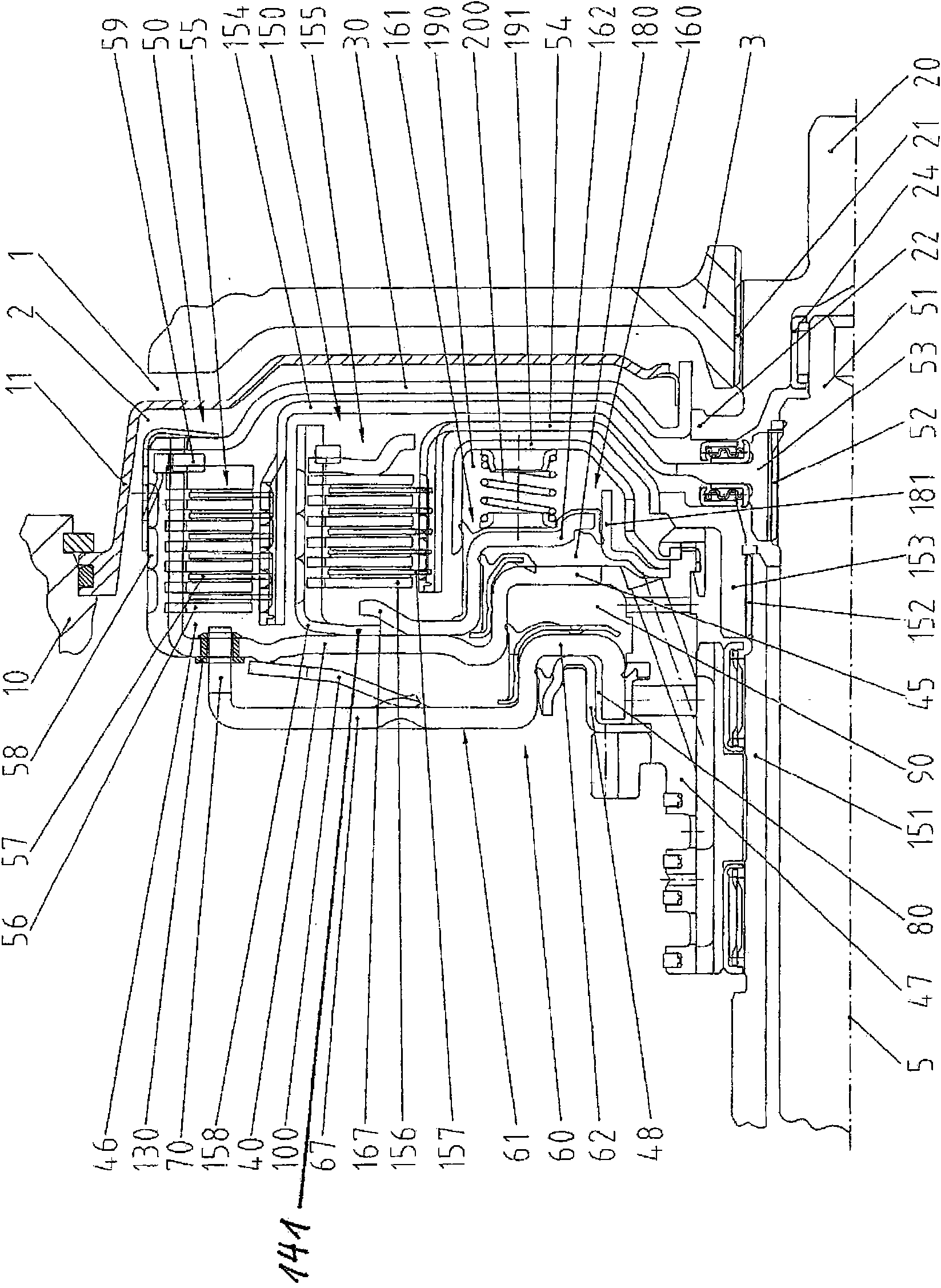

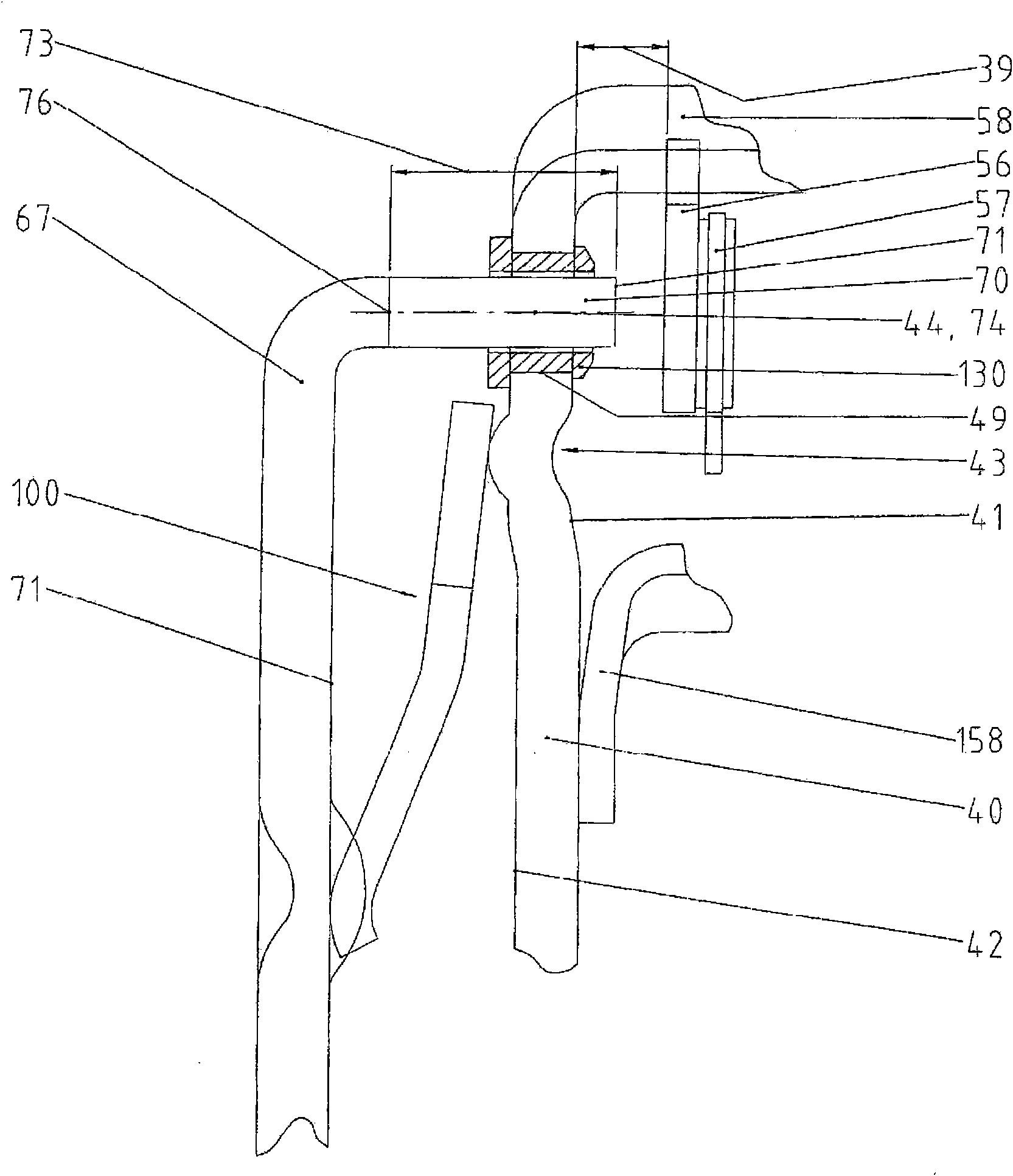

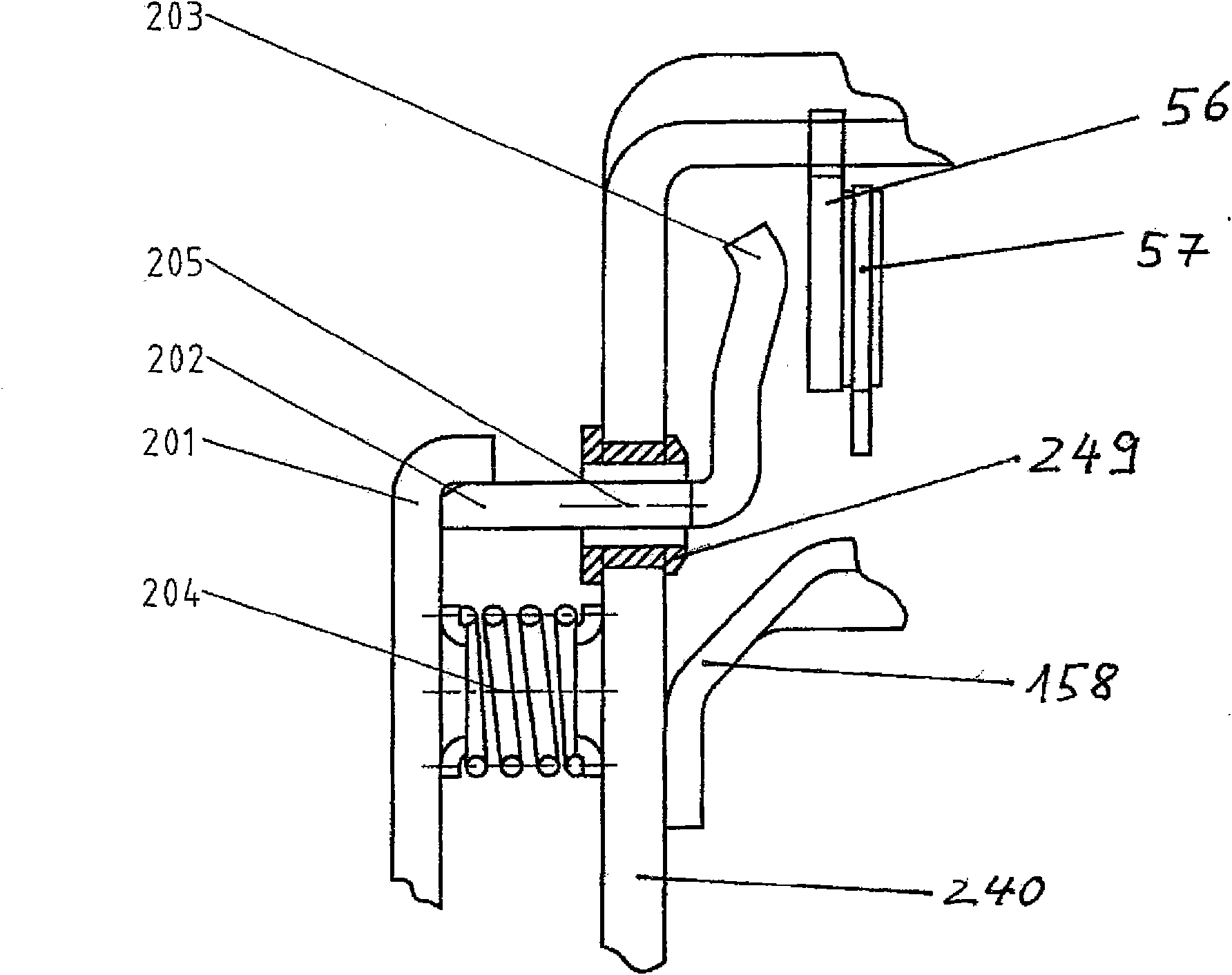

[0024] figure 1 A double shaft clutch with two oil-lubricated friction clutches 50, 150 is shown. This non-positive shifting clutch has two sets of plate packs 55 , 155 arranged radially in sequence. The first plate set 55 is arranged on a larger radius than the second plate set 155 . The two clutches 50, 150 are hydraulically connected. The disengagement of the respective clutches 50 , 150 takes place via spring elements and / or hydraulically via the corresponding cylinder-piston unit. The spring elements 100, 200 are, for example, mechanical springs, such as coil springs and / or diaphragm springs. Such clutch systems are commonly used in passenger cars.

[0025] The clutch system is located, for example, between the multi-shaft transmission of the vehicle and the engine. The engine is usually a gasoline engine or a diesel engine. A single-mass or dual-mass clutch 3 (Ein-oder Zweimassenkupplung) is often installed between the engine and the clutch system.

[0026] Due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com