Method for preparing composite hydrate accelerant

A hydrate accelerator and composite technology, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of unsatisfactory and low gas storage density of hydrate, and achieve low cost, increased gas storage capacity and good conditions Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

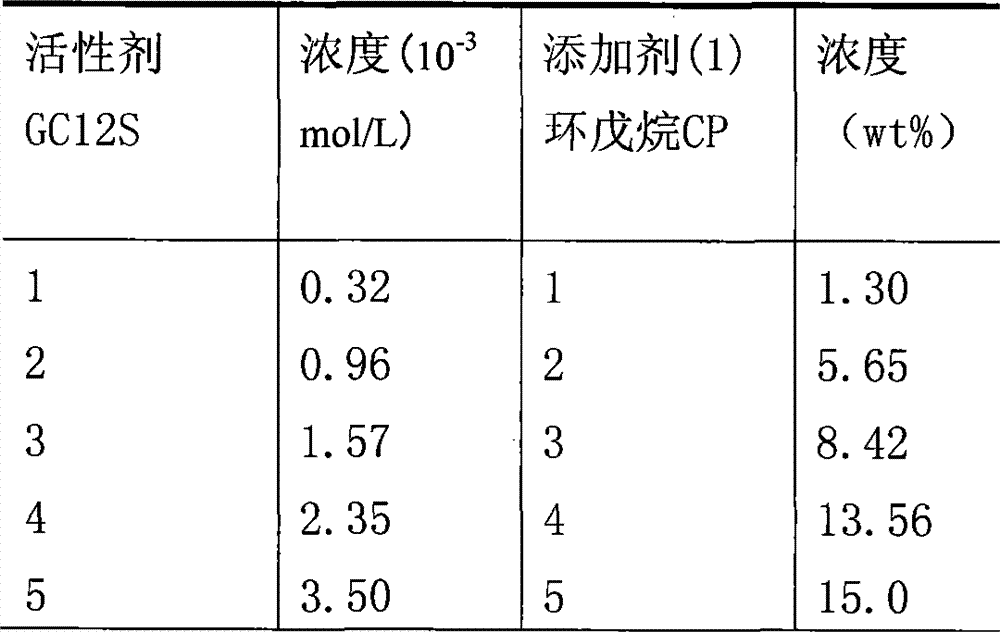

[0034]The selected composite accelerator consists of: kinetic accelerator is cyclopentane CP, accounting for 1.3 to 15.0% by mass of the total solvent, surfactant is 2-butyloctyl sodium sulfate (GC12S), concentration is 0.32×10 -3 ~9.5×10 -3 mol / L (see Table 2). The experimental steps are the same as above. The temperature is 2.1-6.5°C, and the pressure is 0.65-2.4Mpa.

[0035] Table 1 Example 1 System Accelerator Preparation Concentration

[0036]

[0037] Under the above conditions, it is found through experiments that the induction time of hydrate formation is 4-19 minutes; the gas storage density is 163m 3 / m 3 above.

Embodiment 2

[0039] The selected composite accelerator consists of: the kinetic accelerator is methylcyclohexane, accounting for 1.3 to 15.0% of the water contained in the mass percentage, and the surfactant is 2-butyloctyl sodium sulfate (GC12S) , with a concentration of 0.32×10 -3 ~9.5×10 -3 mol / L (see Table 2). Sodium chloride (Nacl) with a mass percent content of 0.02-0.78% is added, and the experimental procedure is the same as above. The results show that the temperature is 2.3-5.3°C and the pressure is 0.62-3.2Mpa.

[0040] Table 2 Example two system accelerator preparation concentration

[0041]

[0042] Under the above conditions, it is found through experiments that the induction time of hydrate formation is 2-15 minutes; the gas storage density is 167m 3 / m 3 above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com