Pressure-adjustable mechanical arm

A technology of pressure regulation and mechanical arm, applied in the field of handling mechanical arm, can solve the problems of complex structure, complex components, high failure rate, etc., and achieve the effect of smooth movement, simple structure and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

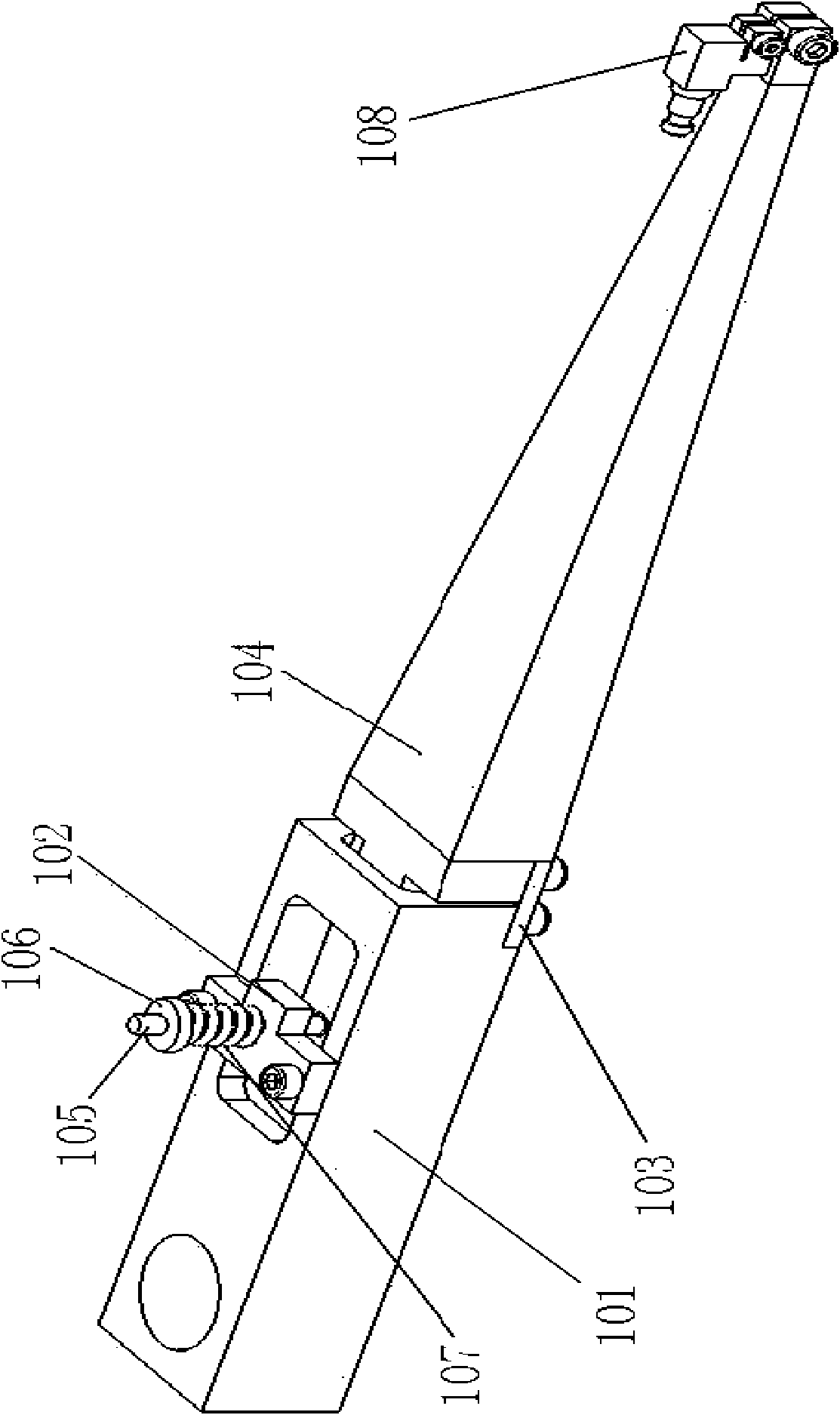

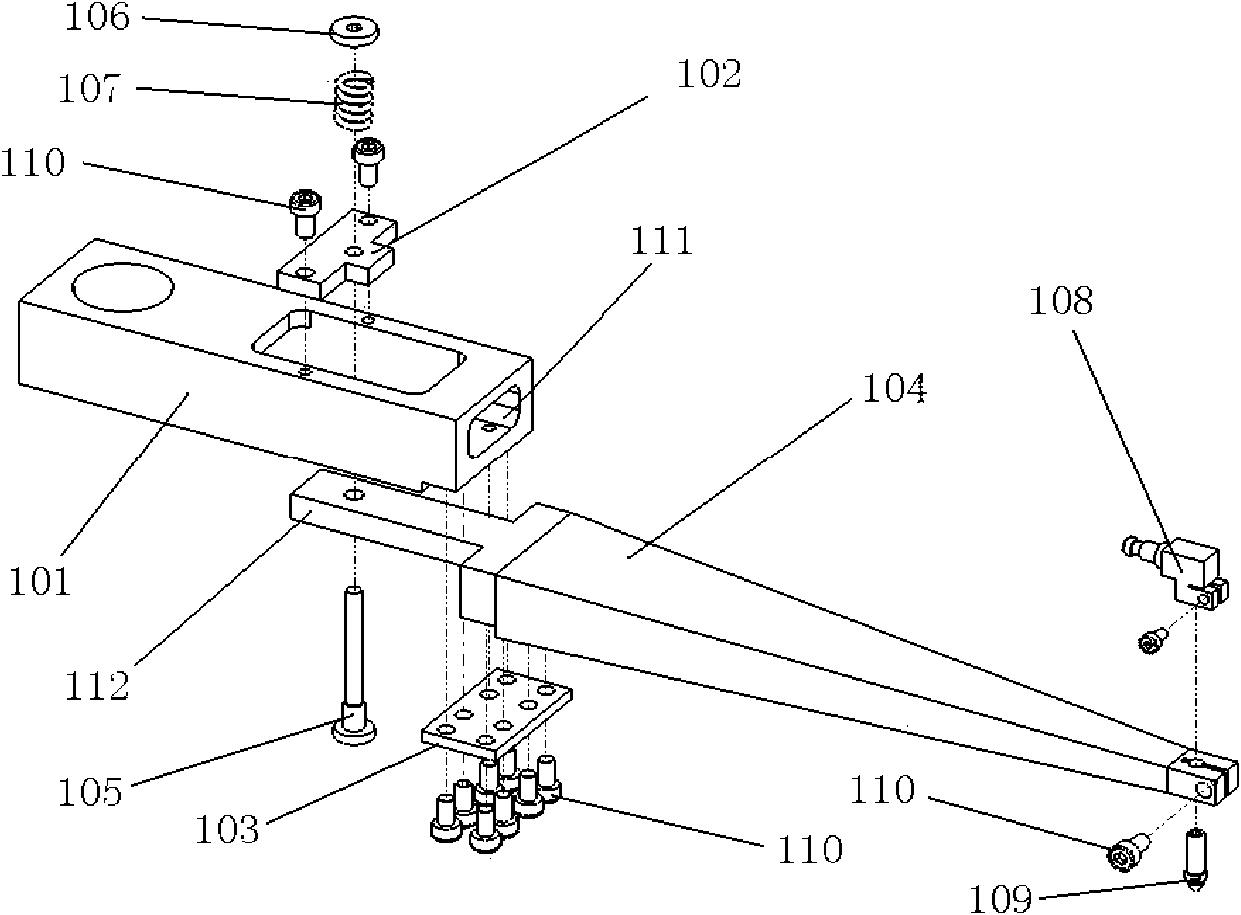

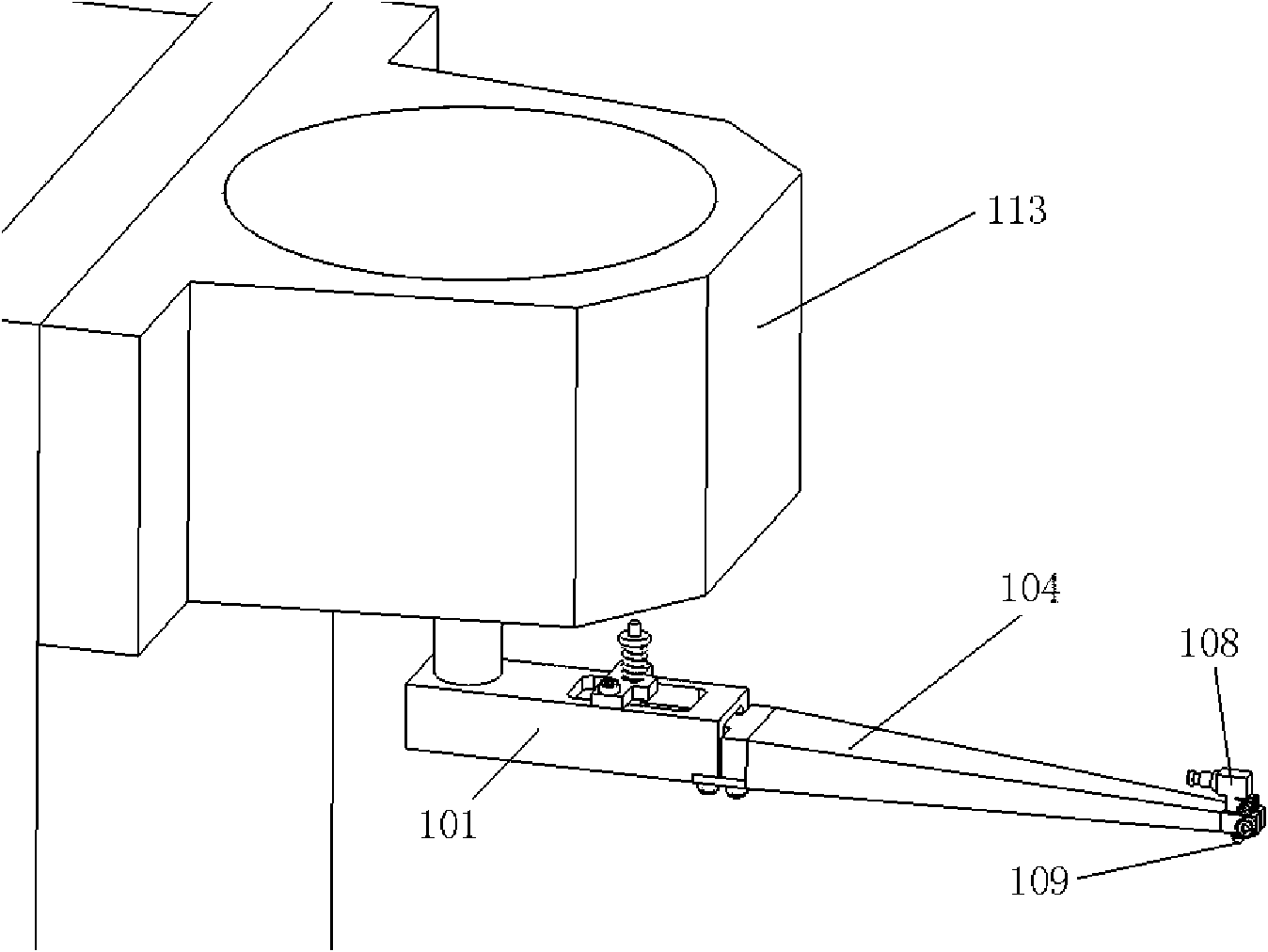

[0012] See attached Figure 1~5 As shown, the numbers in the figure are as follows: 101-rear arm, 102-support plate, 103-elastic sheet, 104-forearm, 105-pressure adjusting rod, 106-pressure adjusting nut, 107-spring, 108--Vacuum nozzle connector, 109--Vacuum nozzle, 110--screw, 111--opening at the front end of the rear arm, 112--rear extension of the forearm, 113--frame.

[0013] The pressure-adjustable mechanical arm of the present invention includes a rear arm 101, a support plate 102 is fixed above the rear arm 101, an elastic sheet 103 is fixed at the front end of the rear arm 101, and the front end of the elastic sheet 103 is fixed together with a forearm 104, and the front end of the forearm 104 has a The vacuum nozzle quick release structure includes a vacuum nozzle 109 and a vacuum nozzle connector 108. The rear extension 112 of the forearm can extend through the opening 111 at the front end of the rear arm, and the rear end of the extension 104 of the forearm is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com