Electro-osmotic consolidation method of large triaxial test of gravel admixture

A technology of triaxial test and electroosmosis, which is applied in the direction of analyzing materials, preparation of test samples, measuring devices, etc., can solve the problems of low test efficiency and long consolidation time, and achieve increased operation difficulty, convenient electrode conversion, and application low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

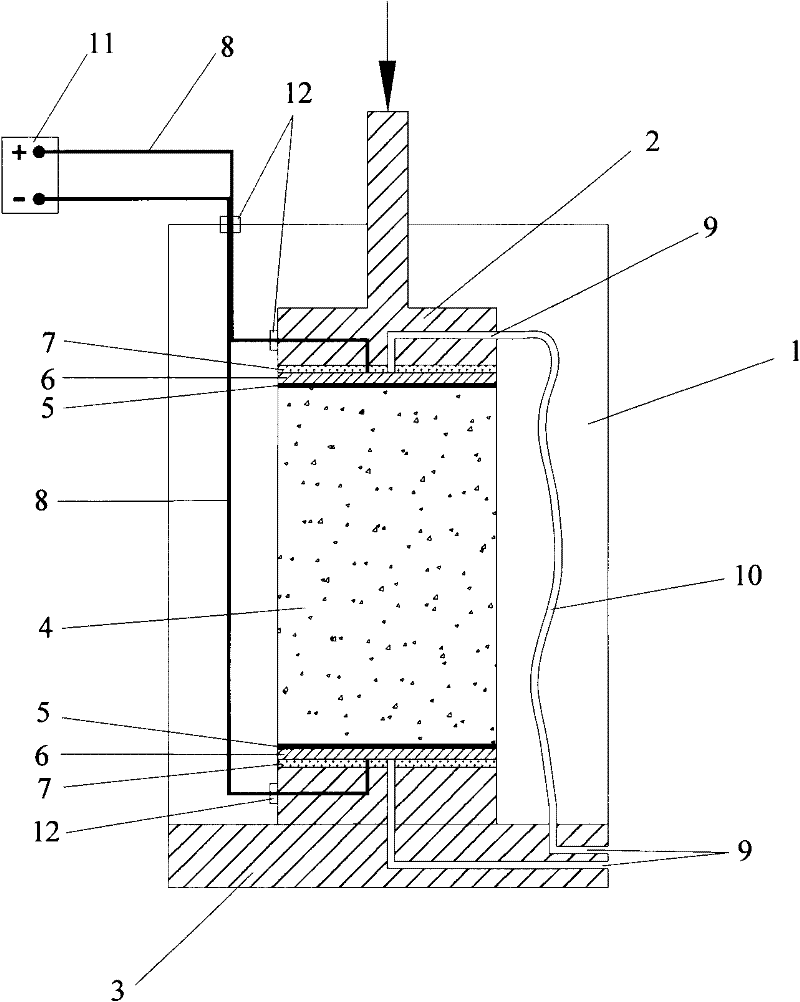

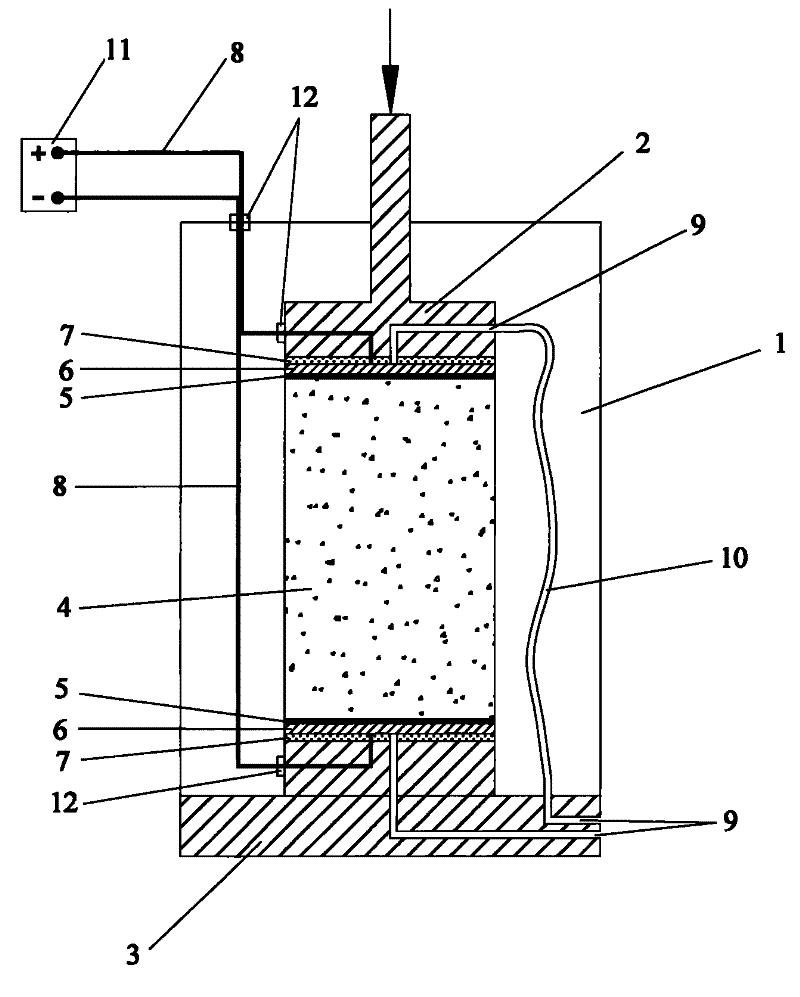

[0027] The method of the present invention is used for the large triaxial test of the gravel core wall material, and its apparatus is as figure 1 shown.

[0028] A large triaxial test electroosmotic rapid consolidation method for gravel-mixed core wall materials, the specific technical steps are:

[0029] (1) On the base 3 and the cover plate 2 of the large-scale triaxial instrument, drain holes 9 and passages for wires to pass through are respectively reserved.

[0030] (2) Place the insulating plate 7 on the base 3. The insulating plate 7 is located on the top surface of the base 3. The diameter is the same as that of the sample 4, which is 300 mm, and the thickness is 1-2 mm. The insulating plate 7 is reserved for the wire 8 to pass through. Aperture, insulating plate 7 is made of insulating hard plastic, requires small deformation, and the effect of insulating plate 7 is to insulate between the lower electrode plate 6 and the base 3 to prevent leakage.

[0031] Place the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com