Double-sealing packing box for oil field wellhead and wellhead double-sealing method

A packing box, double sealing technology, applied in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problem of not reducing the height of the pumping unit, increasing the manufacturing cost of the pumping unit, safety and maintenance costs and other problems, to achieve the effects of compact structure, increased safety and reliability, and fewer accidents in the oil pumping system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

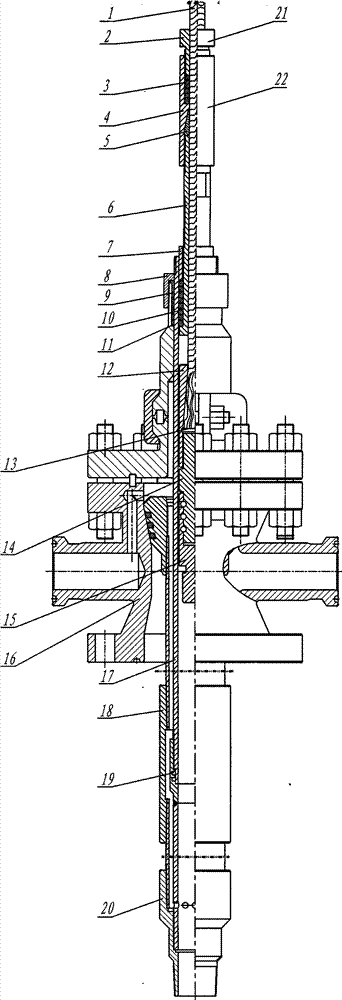

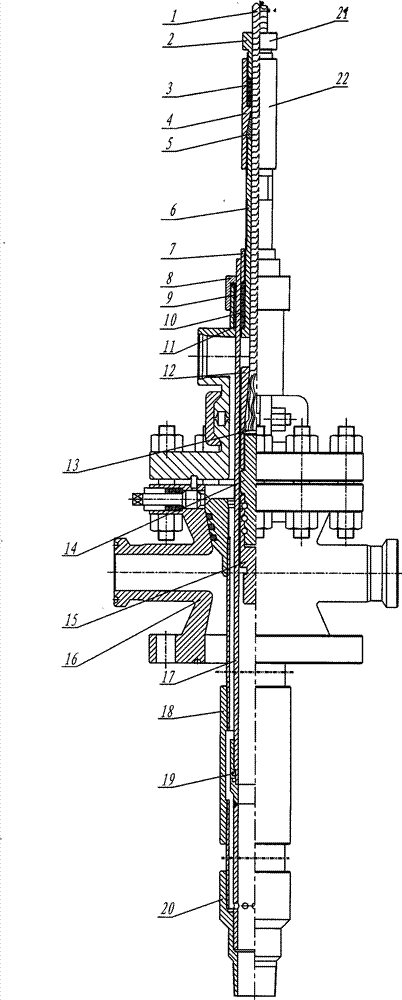

[0020] Oil field wellhead double-sealed packing box, which consists of: a steel wire rope end seal 21 for the steel wire rope 1 to penetrate, the steel wire rope end seal is connected to the packing box sealing device 22, and the packing box sealing device is connected to The large cross 16, the lower end of the upper packing box inner tube 17 of the packing box sealing device is connected to the lower joint 20 of the packing box, and the internal connection of the large cross is a joint 14 for fixing the steel wire rope. The above-mentioned live joint is connected with the steel wire fixed head 13, and the said live joint is connected with the live joint sleeve 15 for connecting the sucker rod.

Embodiment 2

[0022] In the aforementioned oilfield wellhead double-sealed packing box, the wire rope end seal includes a wire rope packing 3, the wire rope packing is connected to the wire rope pressure cap 2, and the wire rope pressure cap and the wire rope packing are sealed and locked sleeve 4, the locking sleeve is connected to the locking slip 5.

Embodiment 3

[0024] In the above oilfield wellhead double-sealed packing box, the packing box sealing device includes a packing bushing 6, and the packing bushing extends into the locking sleeve and is connected to the locking slip 5. The packing sleeve is connected to the packing pressing cap 7, the packing sleeve and the packing pressing cap are connected to the packing 10 together, and the packing pressing cap is connected to the packing inside the upper packing box Pipe 17, the inner tube of the upper packing box is covered with a sealing ring 19; the inner tube of the upper packing box is connected to the large packing 11, the large packing is connected to the large packing gland 9, and the large packing The gland is connected with the large packing gland 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com