Roll changing device for cleaning section of hot dip galvanizing unit

A technology of roll changing device and cleaning section, which is applied in the direction of hot-dip plating process, coating, metal material coating process, etc., and can solve problems such as long working time, safety accidents, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

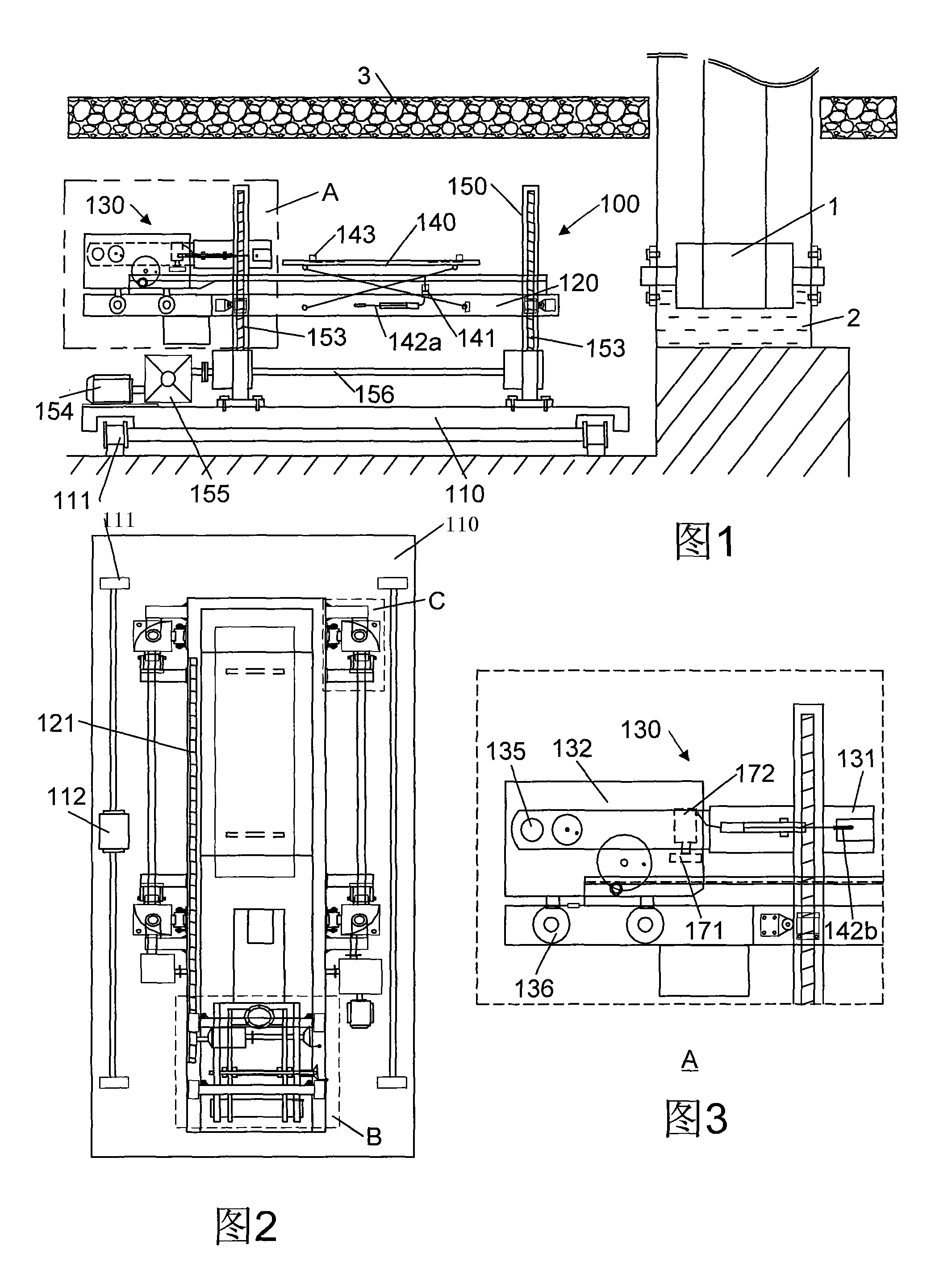

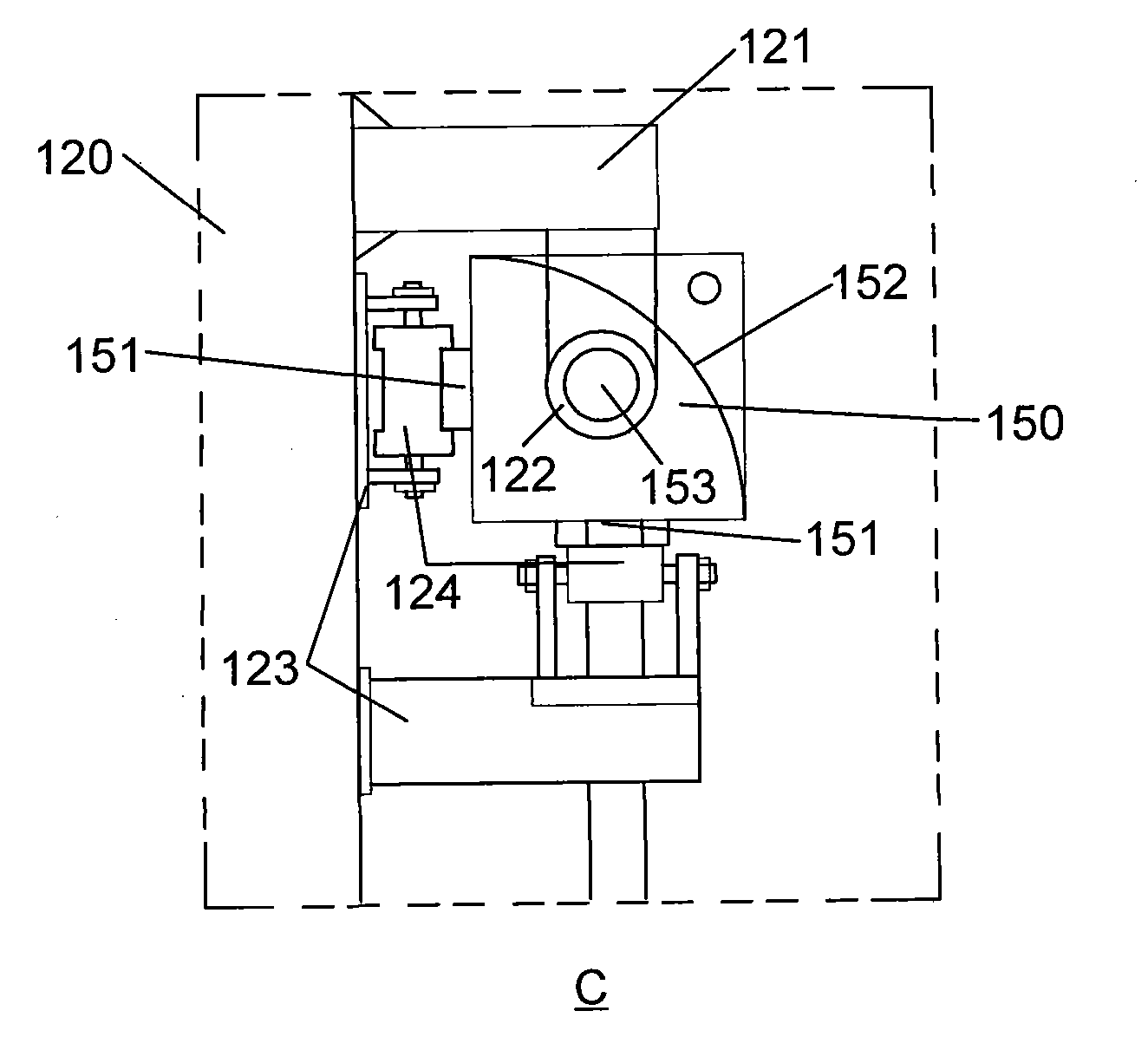

[0021] see figure 1 , figure 2 As shown, the roll changing device 100 of the cleaning section of the hot-dip galvanizing unit of the present invention includes: a base 110 with a walking function; a lifting frame 120 with a lifting function, and the bottom of the lifting frame 120 is fixed on the base 110; The sliding clamping part 130 is arranged on one end of the upper surface of the lifting frame 120 and is slidably connected with the lifting frame 120 ; the bracket 140 for the roller is arranged on the other end of the upper surface of the lifting frame 120 . The bottom of base 110 is provided with walking wheel 111 and walking driving motor 112, can be provided with corresponding track on the ground, walking wheel 111 is located on the track and is connected with walking driving motor 112, drives by walking driving moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com