Steam-resistant environment-friendly ink

A retort-resistant and environmentally friendly technology, applied in the field of ink, can solve problems affecting food quality, etc., and achieve the effects of good heat resistance and stability, strong adhesion, and excellent solvent release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

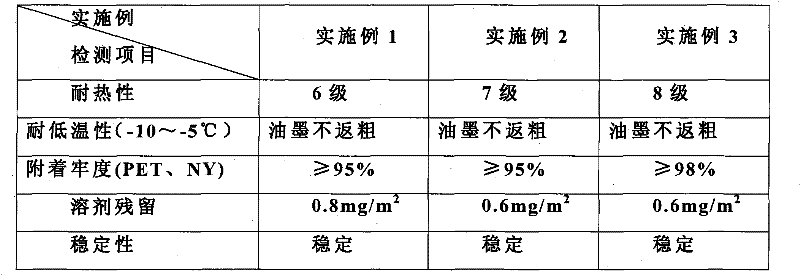

Examples

Embodiment 1

[0016] A retort-resistant environmental protection ink, which consists of: 25 parts (weight) of silicone modified polyamide resin (number average molecular weight is about 200,000), 10 parts of acrylic resin (number average molecular weight 5000), 20 parts of organic red pigment, 15 parts of absolute ethanol, 12 parts of n-propyl acetate; 8 parts of propylene glycol; 1 part of citric acid, 3 parts of dispersant (modified polysiloxane), 3 parts of leveling agent (polydimethylsiloxane), 1 part wax.

[0017] The above ink is prepared by the following method: according to the formula, mix absolute ethanol and propylene glycol in proportion, add silicone modified polyamide resin, acrylic resin and organic red pigment while stirring, stir at high speed for 15 to 30 minutes, and then sand mill Machine grinding and dispersion, when the fineness reaches below 5 microns, add the remaining components and stir to obtain the ink product.

Embodiment 2

[0019] A retort-resistant environmental protection ink, which consists of: 30 parts (weight) of silicone modified polyamide resin (about 300,000 number average molecular weight), 8 parts (weight) of acrylic resin (number average molecular weight 10000), 20 parts of organic yellow pigment, no 12 parts of water ethanol, 12 parts of n-propyl acetate; 11 parts of propylene glycol; 1 part of citric acid, 3 parts of dispersant (modified polysiloxane), 3 parts of leveling agent (polyacrylate copolymer).

[0020] The ink of this example can be prepared according to the same method as Example 1.

Embodiment 3

[0022] A retort-resistant environmental protection ink, which consists of: 34 parts (weight) of silicone modified polyamide resin (about 400,000 number average molecular weight), 8 parts of acrylic resin (number average molecular weight 10000), 20 parts of organic phthalocyanine blue pigment , 12 parts of absolute ethanol, 10 parts of n-propyl acetate; 10 parts of propylene glycol; 1 part of citric acid, 2 parts of dispersant (polycarboxylate amine salt), 3 parts of leveling agent (polyacrylate copolymer).

[0023] The ink of this example can be prepared according to the same method as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com