Rotary power tool operable in either an impact mode or a drill mode

A technology of rotating power and power tools, which is applied in the field of impact drivers, can solve problems such as heavy and bulky, and achieve the effect of low cost and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

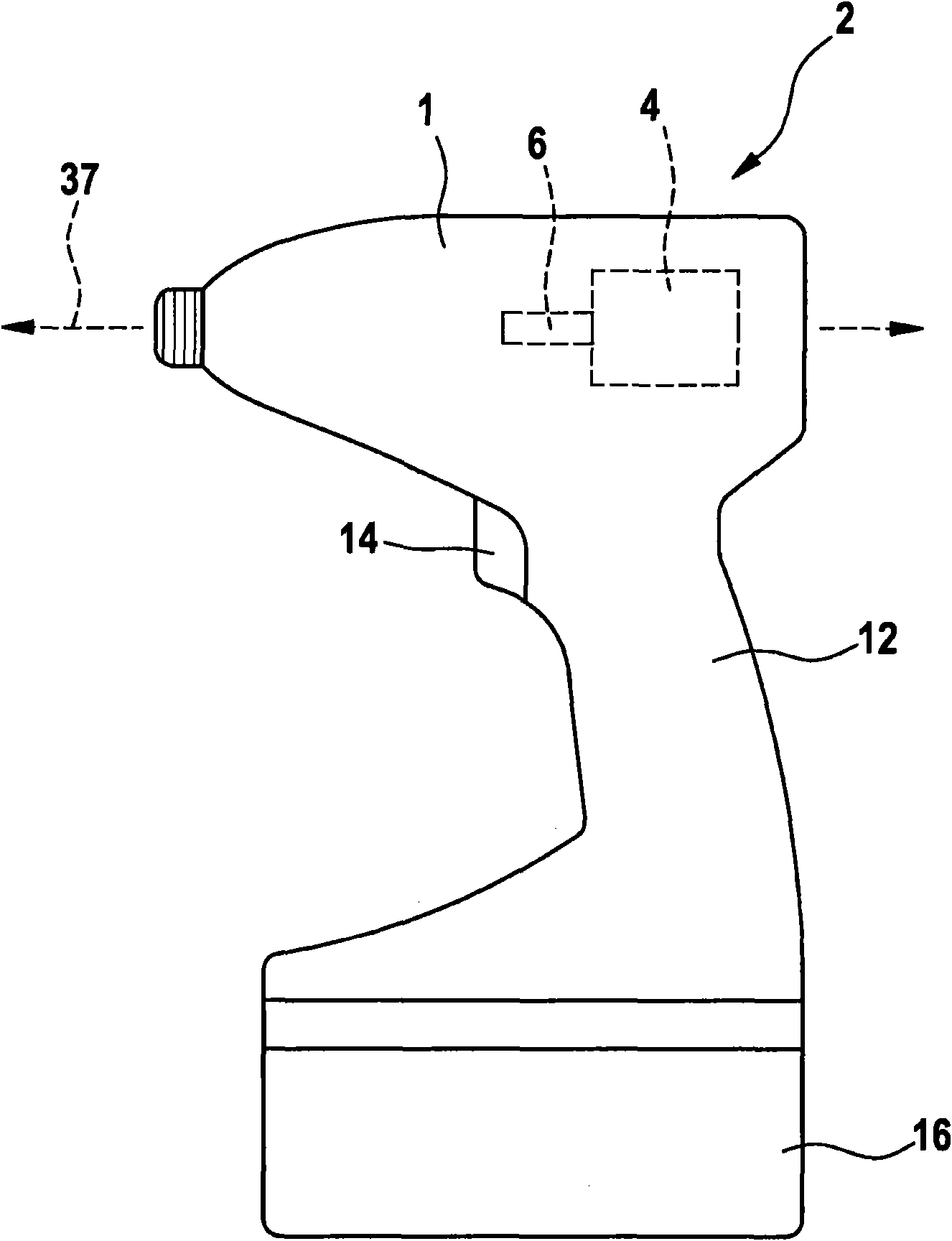

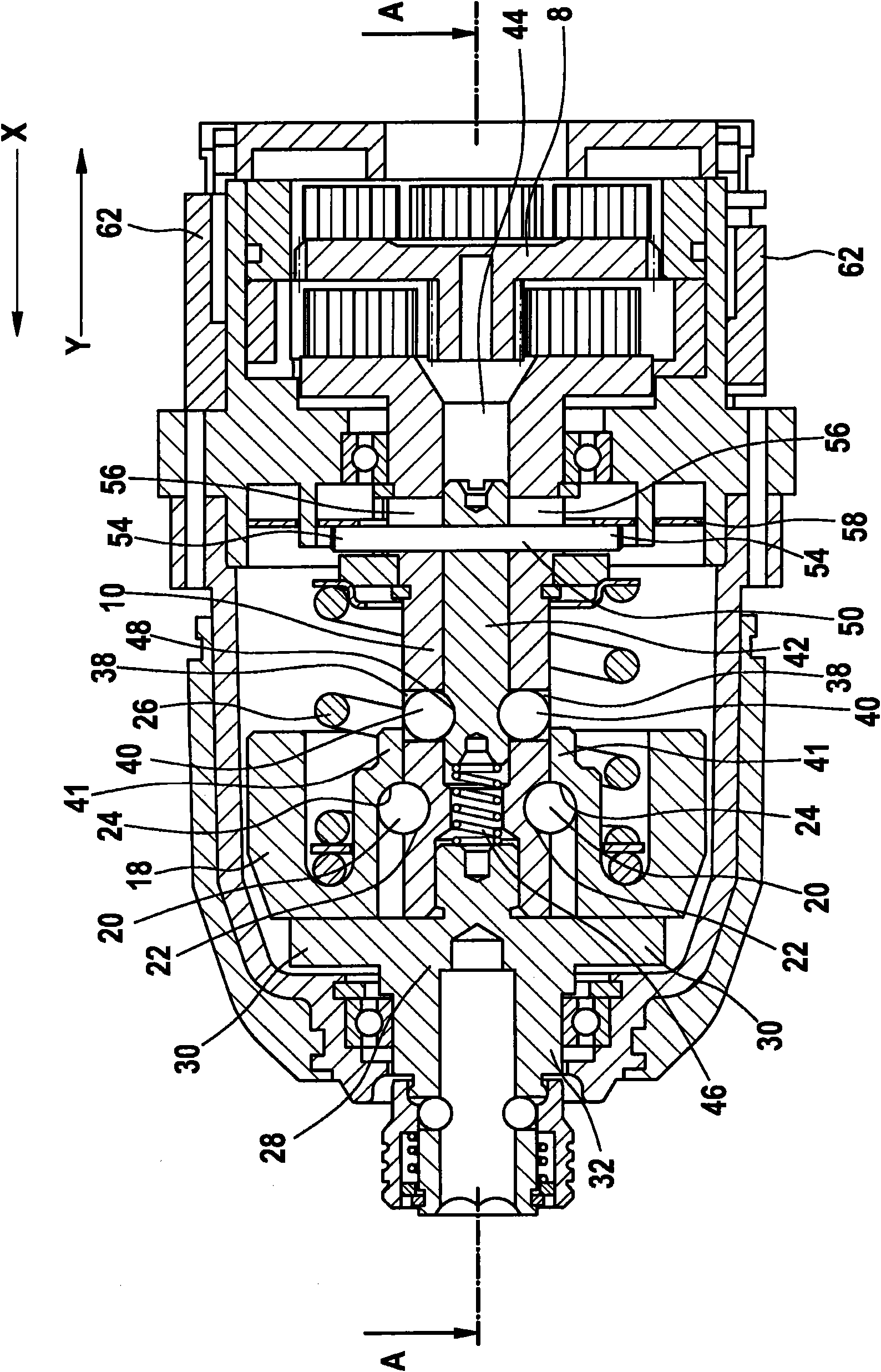

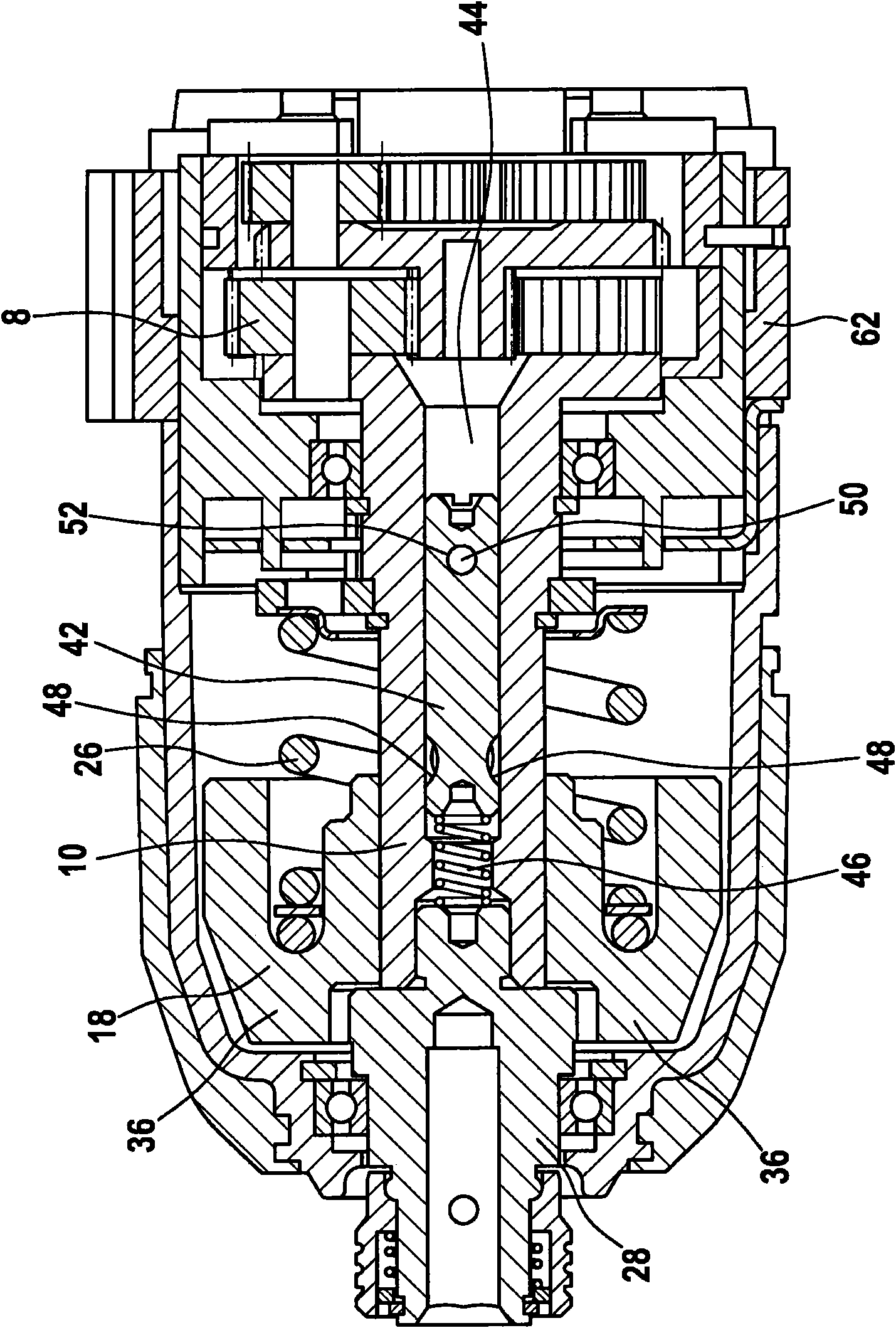

[0022] figure 1 An example of a rotary tool according to the invention is shown. A motor 4 and an associated motor shaft 6 are arranged within the housing 1 of the impact driver 2 . The rotation of the motor shaft 6 is converted through various reduction planetary gears in the gearbox 8 to rotate the drive shaft 10 . The tool is provided with a handle 12 and a trigger 14 so that the user can conveniently operate the tool. A battery 16 provides DC power, but AC power is also a standard alternative.

[0023] The impact driver 2 can operate in at least two different modes, an impact mode and a drilling mode, although it can operate in many more modes. In impact mode, the tool operates like a regular impact driver, delivering intermittent impacts to the output shaft when high torque is required. As will be described below, in drill mode the impact function is turned off and the tool operates more like a standard drill / driver. A comparable impact driver 2 representing a prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com