Self-lubricating plain radial bearing and manufacturing method thereof

A joint bearing and manufacturing method technology, applied in the field of bearings, can solve problems such as low life, limited deformation, and easy failure of rubber, and achieve the effects of reducing wear, increasing service life, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

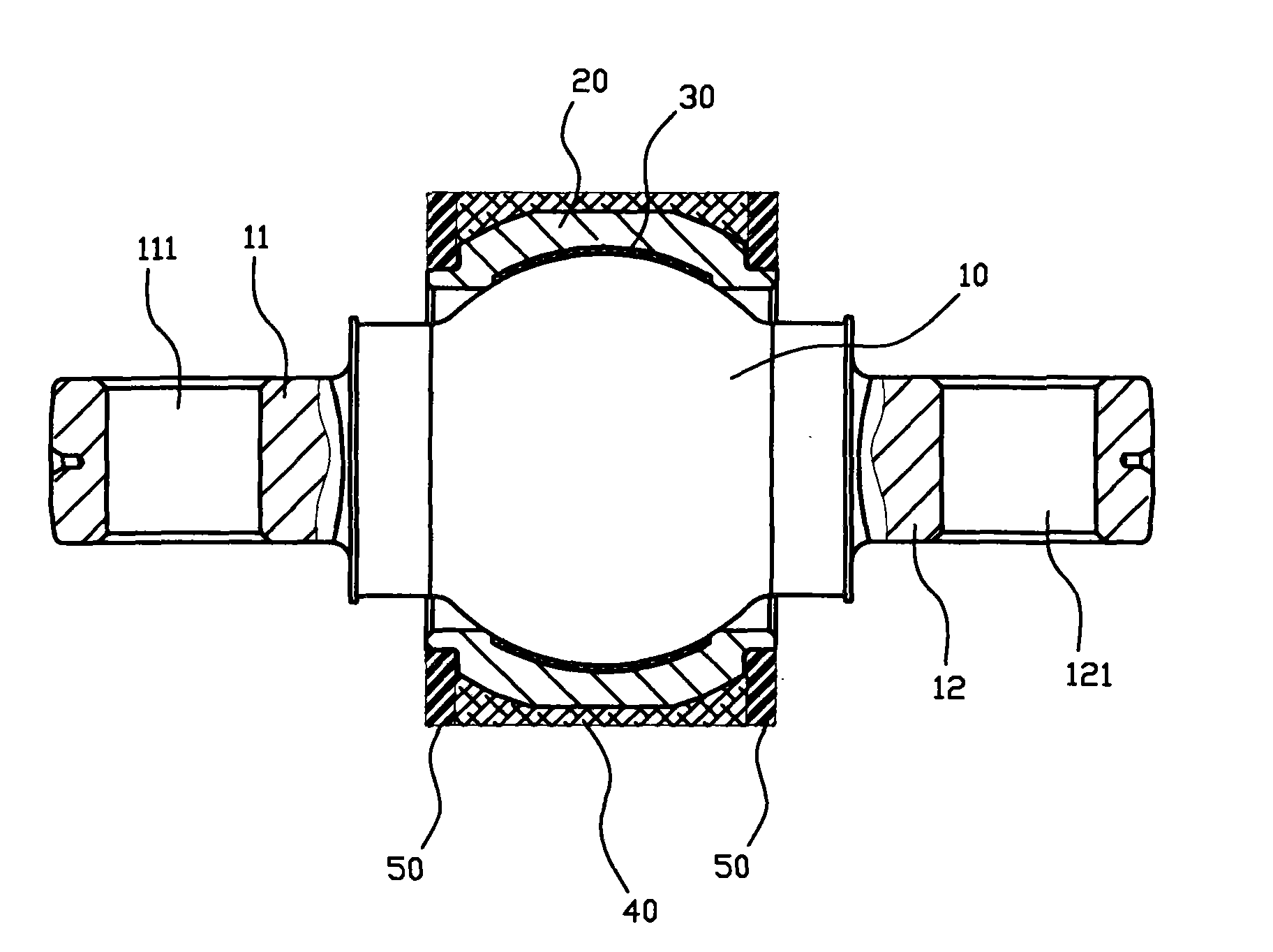

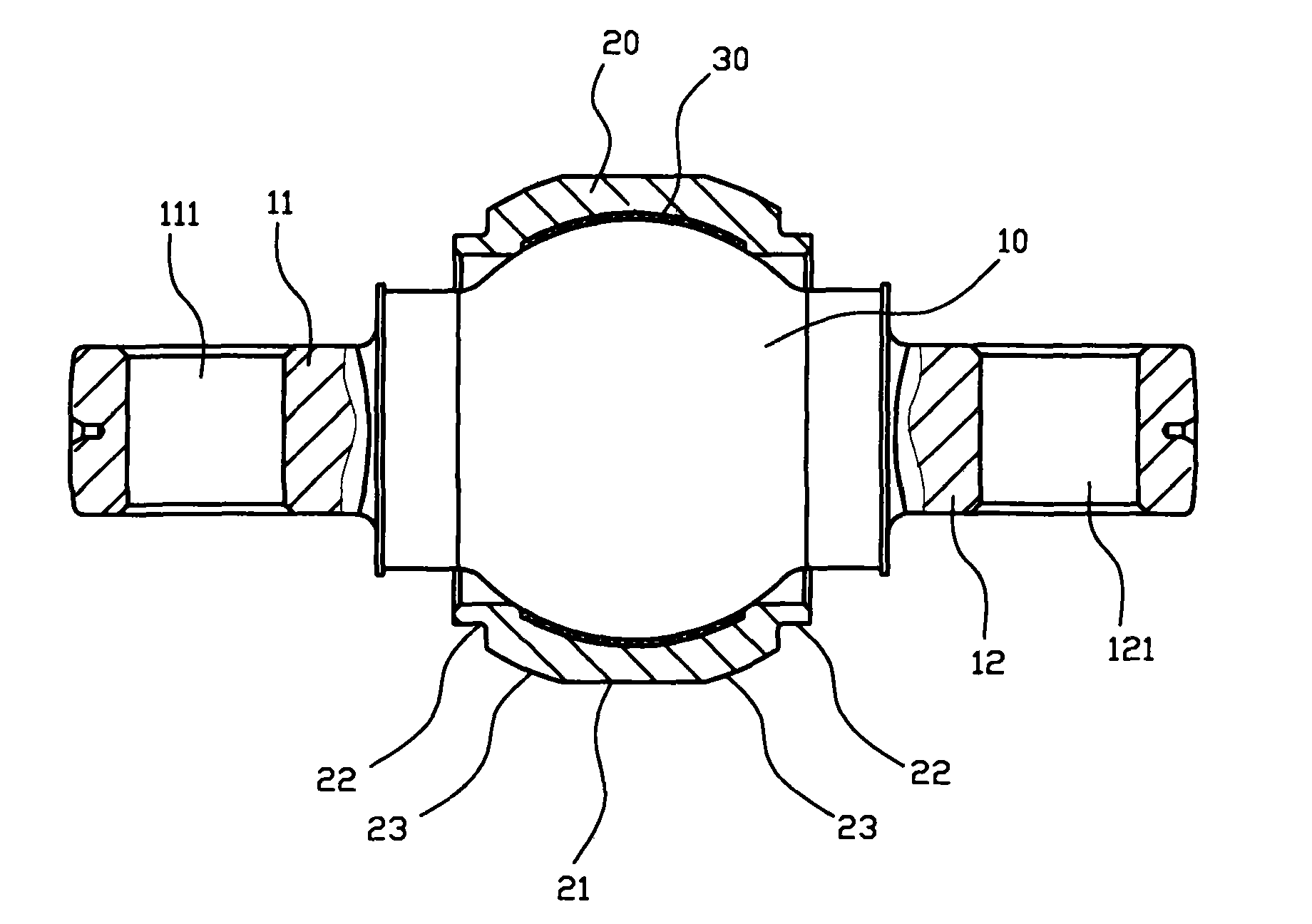

[0022] The present invention will be further illustrated and described below in conjunction with the accompanying drawings.

[0023] refer to figure 1 with figure 2 , a self-lubricating radial joint bearing of the present invention is suitable for a straight ball seat on a V-shaped thrust rod of a truck, and includes an inner ring 10, an outer ring 20, a self-lubricating material liner 30, a rubber body 40 and two The metal end cap 50, the self-lubricating material liner 30 is closely attached to the inner spherical surface of the outer ring 20, the inner spherical surface of the self-lubricating material liner 30 and the outer spherical surface of the inner ring 10 cooperate with each other to rotate, and the rubber body 40 is arranged on the outer ring 20 The outer surface of the outer ring 20, two metal end caps 50 are arranged at both ends of the outer ring 20.

[0024] The inner ring 10 is a solid sphere, and two protruding rods 11, 12 extend outwards from both ends th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com