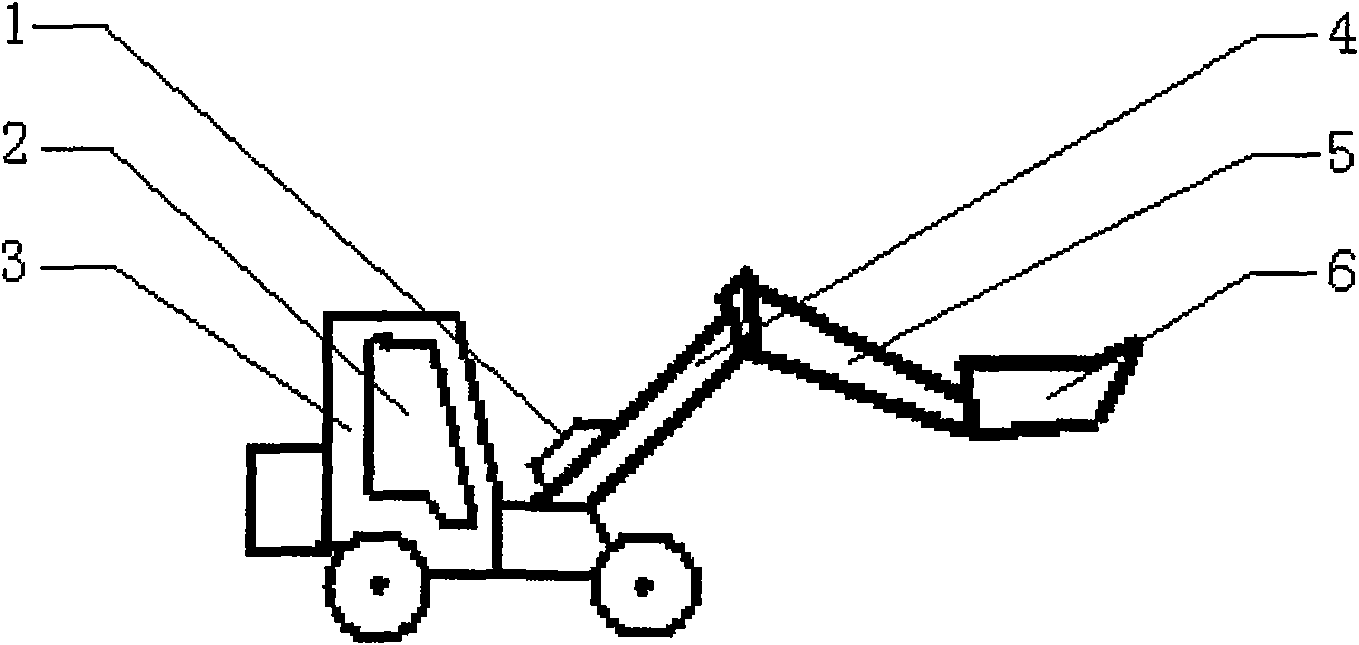

Loading vehicle with vibration exciting structure

A technology for loading trucks and car bodies, applied to mechanically driven excavators/dredgers, etc., can solve problems such as low efficiency, incomplete unloading, and slow speed, and achieve the effect of simple structure and complete unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In addition to the car body 3, the transmission system, and the bucket 6, the loading vehicle with the shock structure provided by the present invention also has a shock structure, wherein the transmission system is composed of a transmission and a drive axle, and the drive axle is composed of a front axle 4 and a rear axle 5 The shock structure is composed of the exciter 1, a control switch and electric wires; the exciter 1 is fixed on the front axle 4; the control switch is fixed on the console of the cab 2 of the car body 3; the electric wire is connected to the exciter 1, the control switch And the power supply in the car body 3. The specific structure of the exciter 1 is the prior art, and the specific form of the electric wires connecting the exciter 1, the control switch and the power supply in the car body 3 is common knowledge, and will not be repeated here. When the present invention is used, the operator turns on the control switch, and the vibrator 1 transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com