Automatic bristle plate binding machine

An automatic, bristle technology, applied in combing machines, mechanical processing, washing/scouring of animal loose hair fibers, etc., can solve the problems of unseen research results, lack of key technologies, uneven quality, etc., to improve the industry. The effect of technological revolution, stable and reliable quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

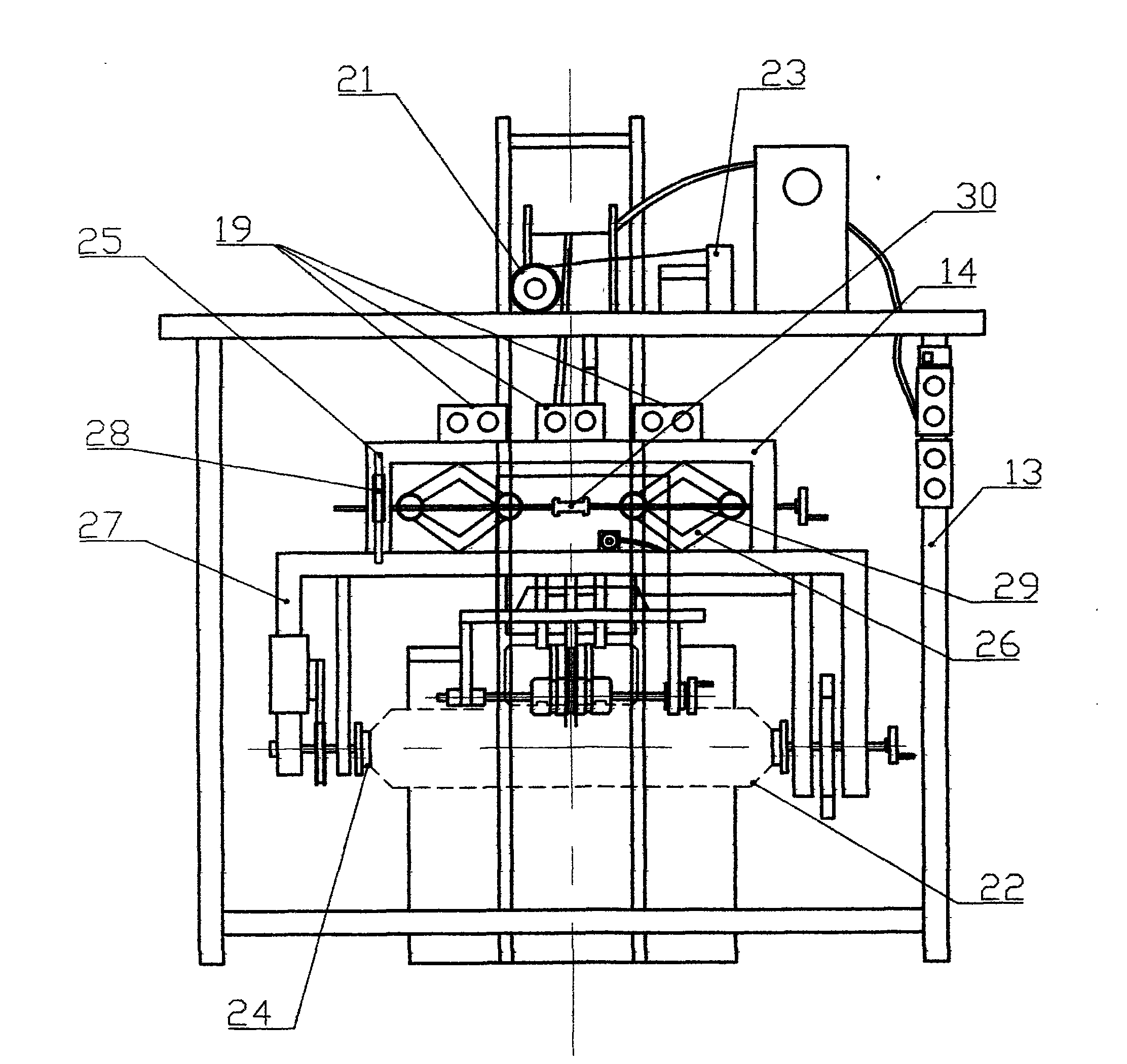

[0014] The present invention will be described in detail with reference to the accompanying drawings.

[0015] The bristle automatic binding machine is composed of a cleaning and stirring device, a transmission carding device and a binding forming device installed on the frame 1; The transmission combing device is connected, and the transmission combing device is connected with the binding forming device through the transmission belt 9, the binding rope 18, the rotating belt II 8.1, and the binding bracket 13; , stirring rod driving wheel 5 and stirring rod 6, stirring rod driving wheel 5 is fixed on one side of cleaning pool 2, one end of the central rotating shaft 6.1 of stirring rod 6 is fixed on stirring rod driving wheel 5, and the other end is fixed on the cleaning pool 2. On the other side, the stirring rod 6 rotates with the stirring rod driving wheel 5; wherein the stirring driving motor 3, several transmission wheels 14 and the stirring rod driving wheel 5 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com