Harvesting unit body of small row spacing corn harvesting machine

A corn harvester, small row spacing technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of inability to meet the use requirements and high production costs, and achieve the effects of compact structure, low cost and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

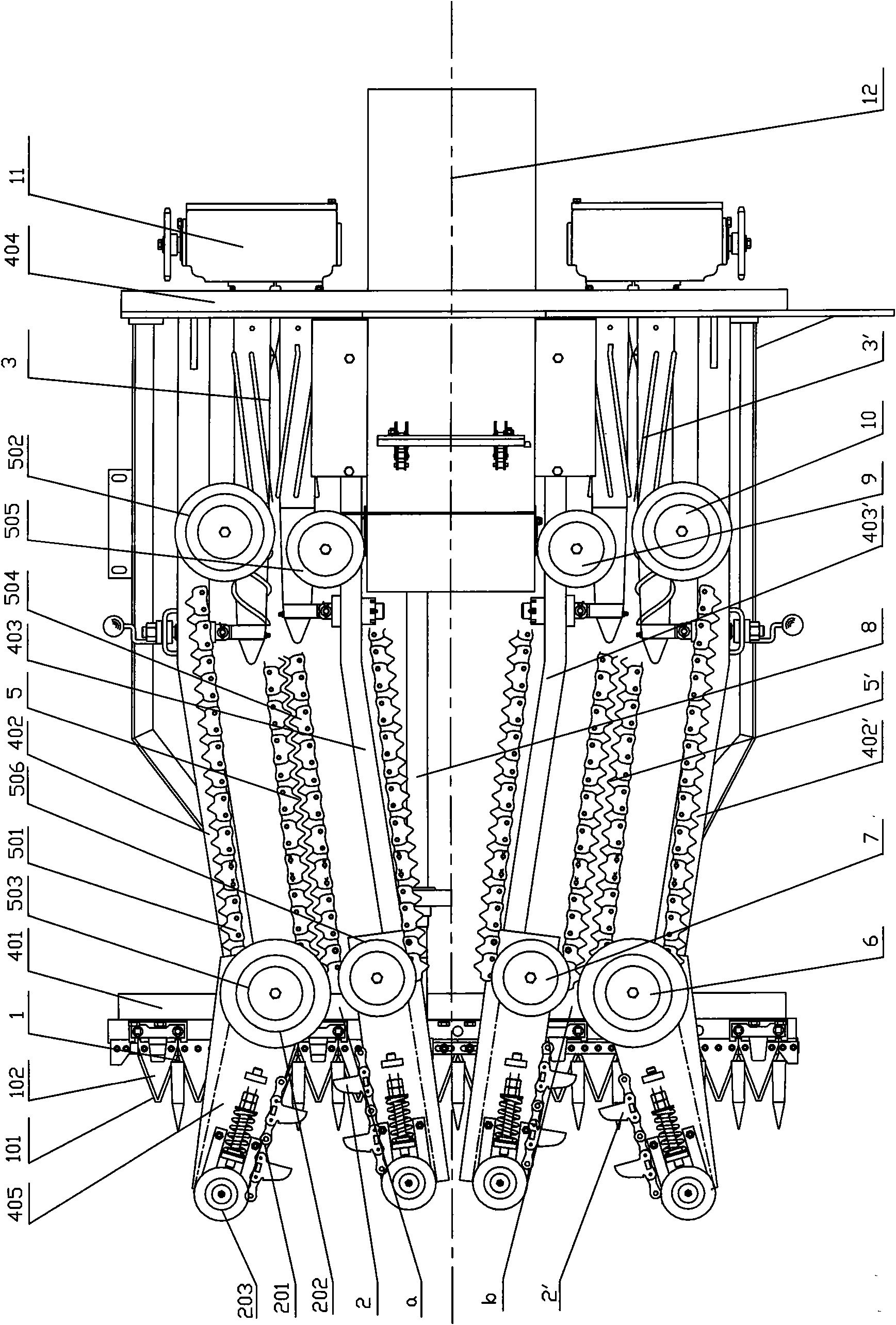

[0015] As shown in the accompanying drawings, a harvesting unit body of a small row-spacing corn harvester includes several groups of harvesting bodies provided on the header fixing frame 4 and a frame body 401 mounted on the front end of the header fixing frame. 1. A straw cutter 1 composed of a moving knife 102.

[0016] Wherein, each group of harvesting bodies includes a pair of fringe-picking rollers 3 installed on the rear end 404 of the header fixing frame, the vertically inclined axes are parallel, and the heights are staggered;

[0017] And a pair of reeds installed on the connecting frame body 405 at the front end of the header fixing frame, which is an angular structure with an outward opening, and consists of a driving sprocket 202 for reeling, a driven sprocket 203 and a chain 201 with a dial. 2;

[0018] And on the header fixing frame body 402,403 between the reel outlet of each pair of reel 2 and the lead-in end of ear picking roller 3, respectively install a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com