Raw film for retardation film, retardation film, and liquid-crystal display

A phase difference film and film technology, which is applied in liquid crystal materials, instruments, optics, etc., can solve the problems of film transparency reduction, front contrast reduction, uneven orientation, etc., and achieve the effect of excellent front contrast and low internal turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

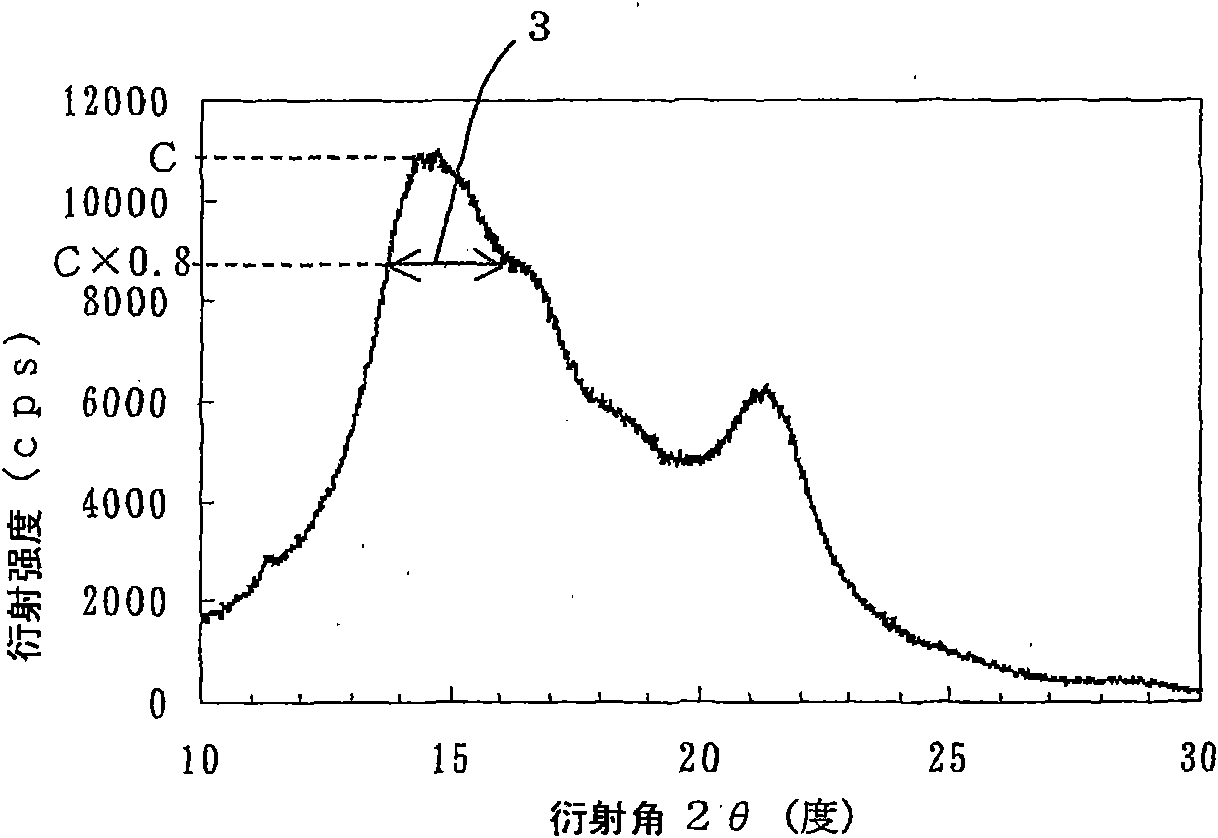

[0105] A propylene-ethylene random copolymer (MFR=8g / 10min, ethylene content=4.6% by weight) was added to a 50mmφ extruder with a cylinder temperature set at 250°C for melt kneading, extruding at 13kg / h The output was extruded from a 450 mm wide T-die mounted on the above-mentioned extruder. The extruded molten sheet is nip-cooled by a 250mmφ cooling roll whose temperature is adjusted to 13°C, a metal sleeve (outer cylinder) whose temperature is adjusted to 13°C, and a touch roll composed of an elastomer roll inside. , to obtain a film with a thickness of 100 μm. The nip line pressure at this time was 5 N / mm, and buildup did not occur between the cooling roll and the touch roll. The distance between the discharge port of the T-die and the roll (air chamber) was 20 mm, and the distance between the cooling roll and the touch roll for nipping the sheet was 10 mm. Various samples for evaluation were collected from the films thus obtained. The melting point of the sample was 136...

Embodiment 2

[0110] A propylene-ethylene random copolymer (MFR=1.5g / 10 minutes, ethylene content=5.7% by weight) was added to a 65mmφ extruder with a cylinder temperature set at 240°C for melt kneading at a rate of 46kg / h The extruded amount was extruded from a 1200 mm wide T-die installed in the above-mentioned extruder. The extruded molten sheet is nip-cooled by a 400mmφ cooling roll whose temperature is adjusted to 13°C, a metal sleeve (outer cylinder) whose temperature is adjusted to 13°C, and a touch roll composed of an elastomer roll inside it, A thin film with a thickness of 200 μm was obtained. The air chamber was 150 mm, and the distance between the cooling roll and the touch roll to nip the sheet was 20 mm. Various samples for evaluation were collected from the films thus obtained. The melting point of the sample was 129° C., and the in-plane retardation was 3025 nm. In the entire area of the X-ray diffraction curve of the sample, the ratio of the area under the curve origin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com