Pull-out mechanism for a drawer

A drawer and track technology, applied in the field of pull-out mechanism, can solve the problems of complex and easily damaged pull-out mechanism, and achieve the effects of simple, reliable transmission and reliable sliding of the pull-out mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

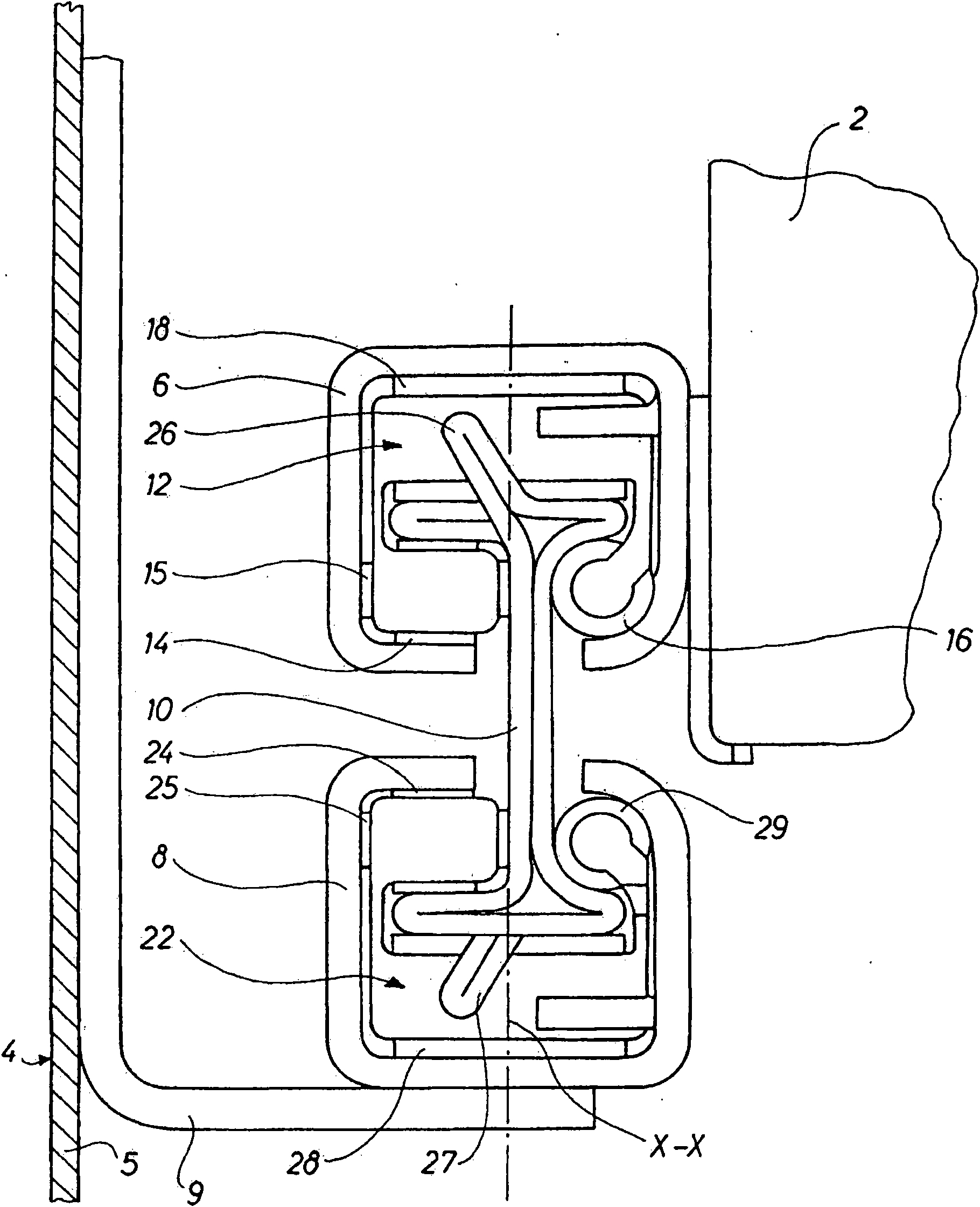

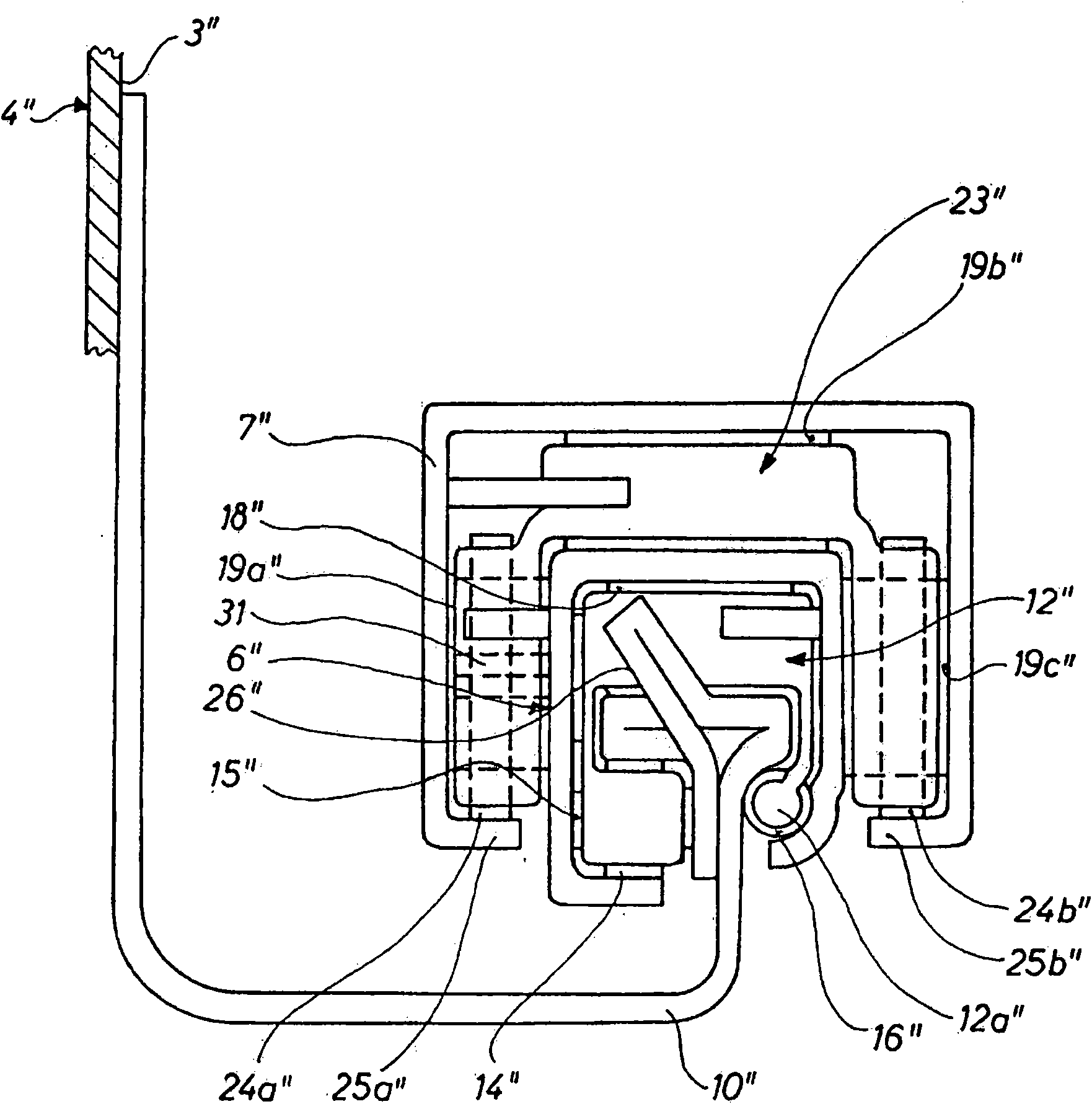

[0018] figure 1 and 4 The pull-out mechanism 1 shown in is used to install a preferably large and heavy drawer 2 in a drawer cavity 3 in a piece of furniture 4 . This piece of furniture 4 can be, for example, a filing cabinet. The pull-out mechanism 1 comprises an upper pull-out rail 6 and a lower rail 8, the upper pull-out rail 6 is in the longitudinal direction of the drawer (ie perpendicular to figure 1 The direction of the middle file plane) is fastened to the drawer 2, while the lower rail 8 is fastened to the wall 5 in the drawer cavity 3 of the piece of furniture 4 by means of fittings 9. An intermediate rail 10 is interposed between the upper rail 6 and the lower rail 8, said intermediate rail 10 being movable in its longitudinal direction, see Figure 4 , while the middle track 10 is placed between tracks 6 and 8 . Between the middle rail 10 and the upper rail 6 - while at the same time to the left of this middle rail 10, especially its vertical center plane X-X -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com