Draining pump

A technology of drainage pump and pump cover, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of unsatisfactory water retaining effect of water retaining ring, low drainage pressure, and inability of drainage pump to drain water, etc. Practical and promotional value, the effect of increasing the drainage pressure and improving the water retaining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

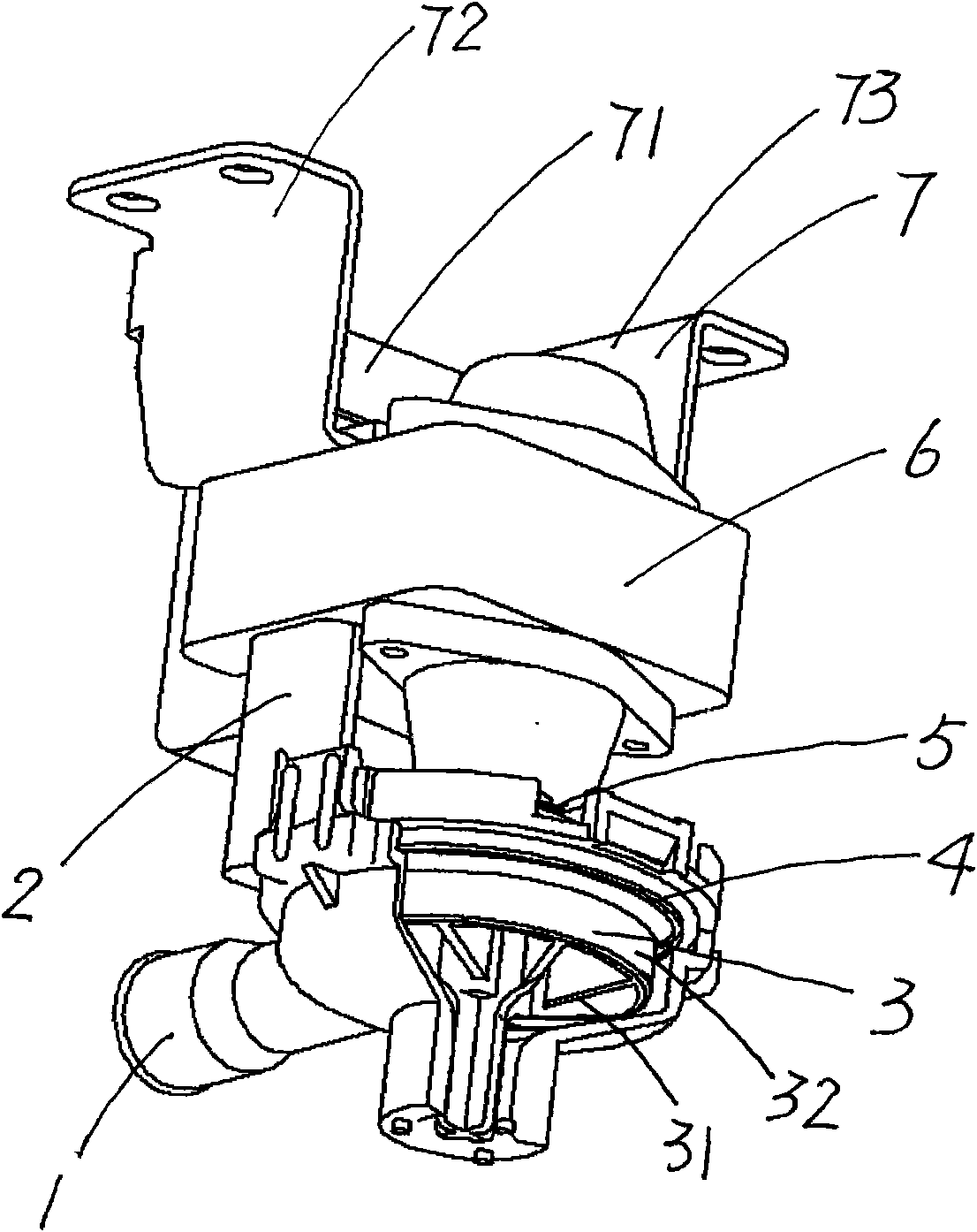

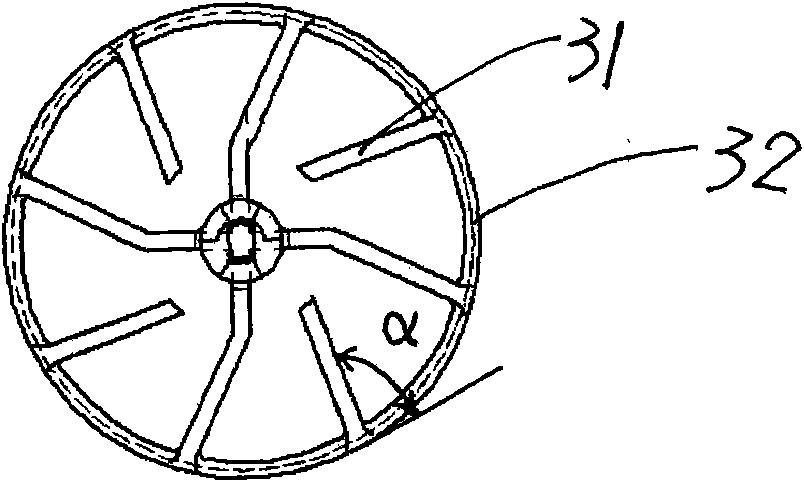

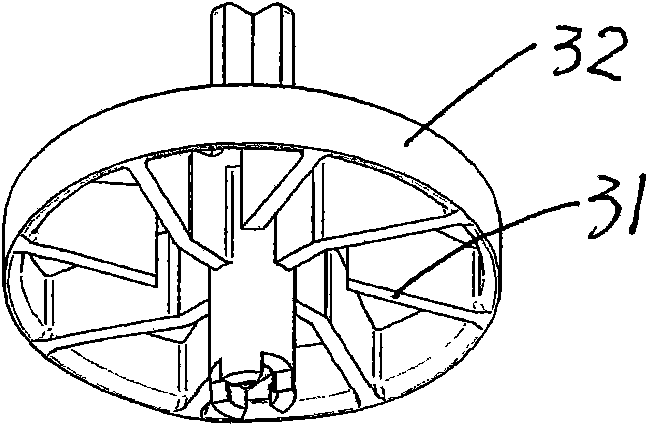

[0018] Refer to attached figure 1 , attached figure 2 , attached image 3 , a drainage pump of the present invention, which is composed of a pump cover 1, a bracket 2, an impeller 3, a sealing ring 4, a water retaining ring 5, a shaded pole motor 6, and a fixed bracket 7, and a bracket is fixed on the shaded pole motor 6 2. The impeller 3 connected with the shaded pole motor 6 is arranged in the inner cavity of the pump cover 1 under the bracket 2; the water retaining ring 5 is arranged on the shaft of the shaded pole motor 6; the sealing ring 4 is arranged on the bracket 2 and At the junction of the pump cover 1, a fixed bracket 7 with a side reinforced connecting plate 71 is also provided on the shaded pole motor 6, and the reinforced connecting plate 71 of the fixed bracket 7 is in phase with the bracket seat I 72 and the bracket seat II 73. connect. The blade 31 in the impeller 3 and the tangent to the impeller side 32 form an inclination angle α, and the inclination a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com