Ejecting type anti-winding bottle cap and manufacturing method thereof

A technology of ejecting caps, applied in the field of caps, which can solve the problems of short ejecting distance, instability and poor sealing of caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

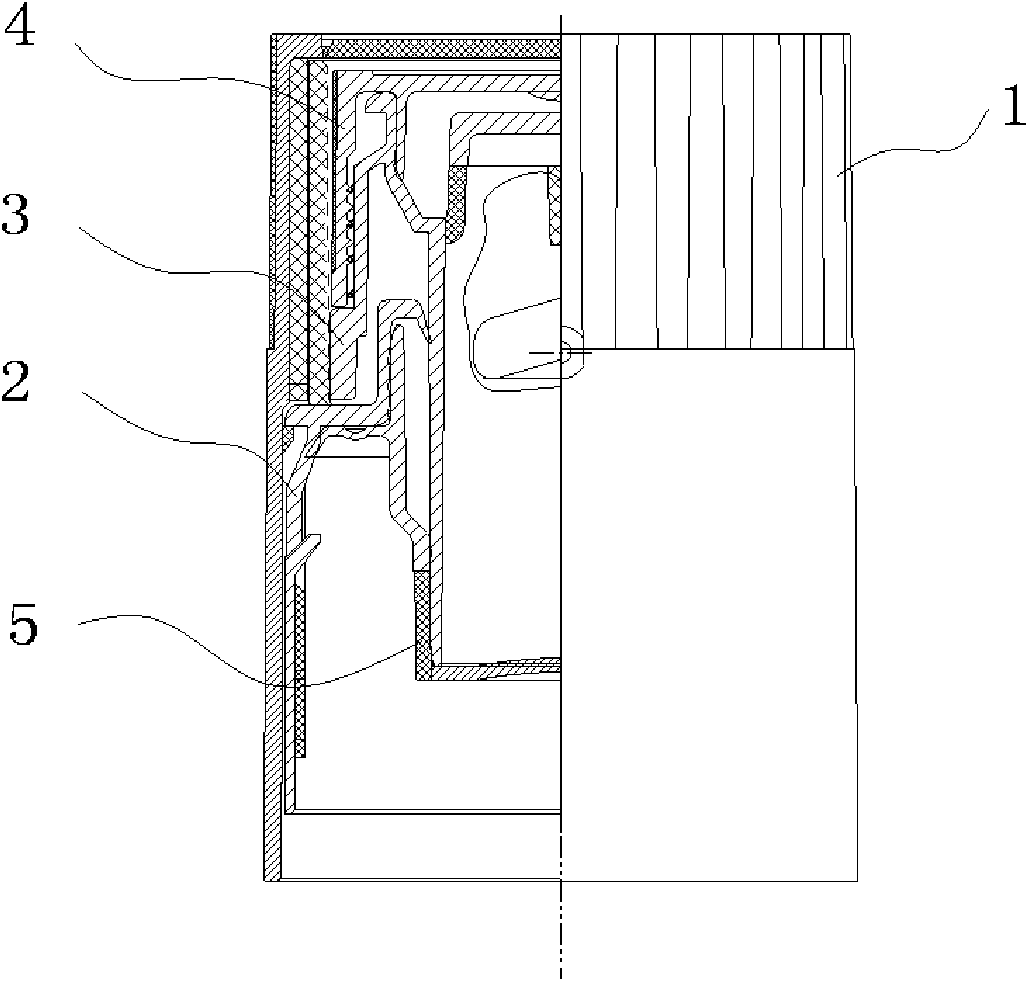

[0023] see figure 1 , This embodiment includes an outer jacket 1, a middle sleeve 2, a connecting cover 3, an upper cover 4, and an inner plug 5.

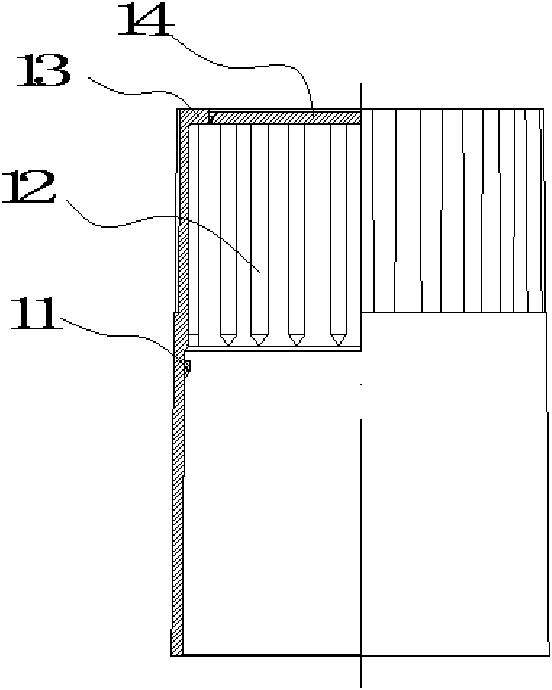

[0024] like figure 2 As shown, the overcoat 1 is a cylindrical structure, the upper end is provided with an ejection piece 14, and guide grooves 12 are evenly distributed on the entire inner wall, and the lower end of the guide groove 12 is provided with a limit rib 11, and the lower end of the guide groove 12 is connected to the limit rib. The distance between the ribs 11 is equal to the thickness of the positioning ring 24 in the middle cover 2, and the top port of the overcoat 1 is provided with a flange 13, and the flange 13 is provided with four points to connect with the ejector sheet 14.

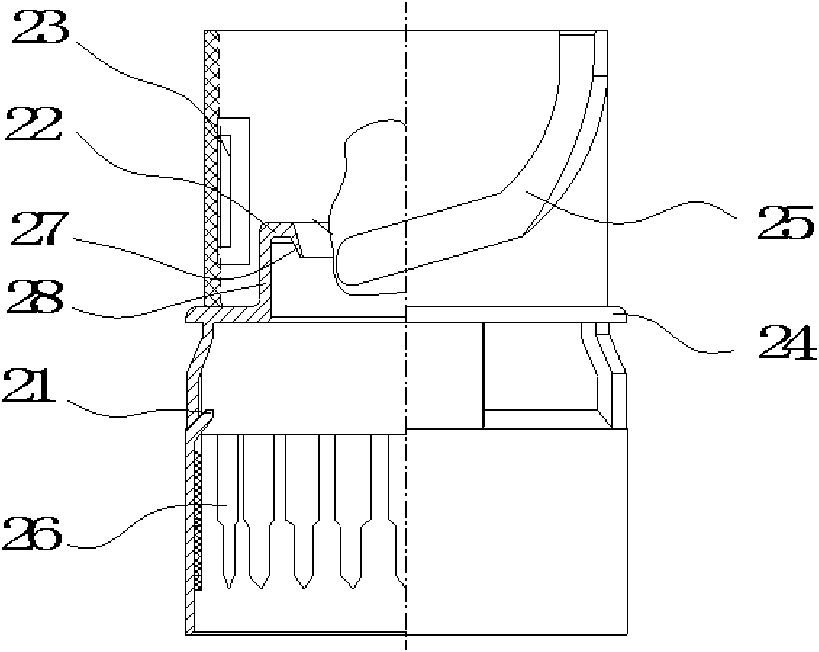

[0025] see image 3 , the middle sleeve is divided into u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com