Sludge conditioner and sludge dewatering method thereof

A technology for sludge conditioning and water sludge, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve problems such as complex preparation process, and achieve the effect of improving dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described further below by embodiment, and its purpose is in order to better understand content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

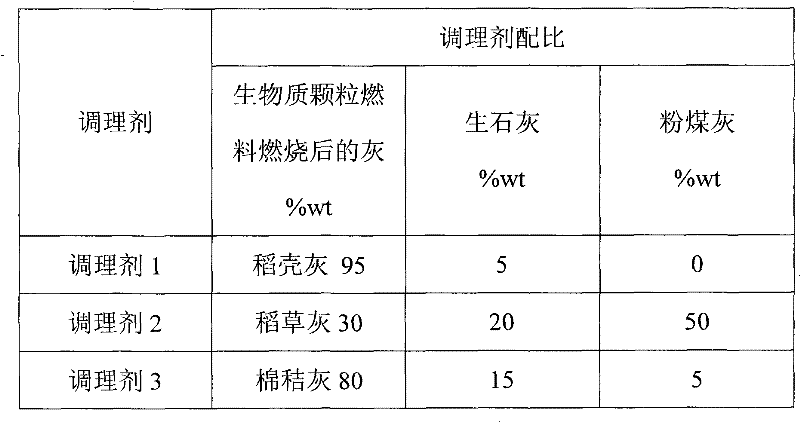

[0022] Table 1 lists the proportions of twelve examples, the preparation method of which is mechanical mixing.

[0023] Weigh the sludge sample to be conditioned in a 2000ml beaker, add a specified amount of conditioning agent, stir continuously at room temperature for 30min at a stirring speed of 400 rpm, and then pour it into a Buchner funnel. The sludge specific resistance adopts a conventional measurement method: the sludge dehydration test is carried out with a vacuum degree of 0.08MPa. Record the filtration time T, the filtrate volume V at the corresponding time and the total volume of the filtrate, and calculate the sludge specific resistance. The amount of water-containing sludge used in each experiment was 1000 g. The propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com