Anti-static guide mechanism of insulated paper board laminating machine

A technology of insulating cardboard and guiding mechanism, which is applied in the field of transformers, and can solve the problems of difficult detection of dust and dust scattering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

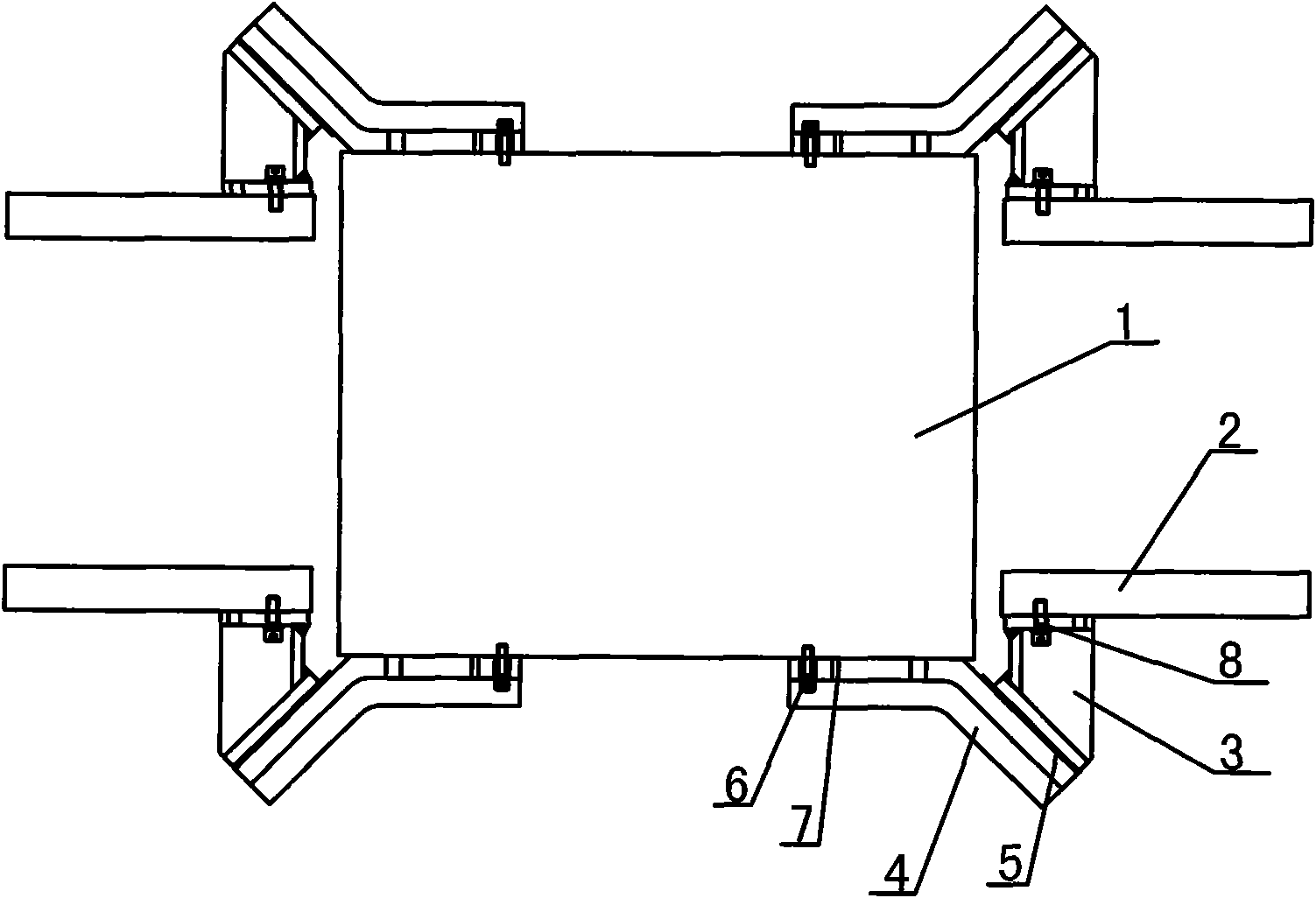

[0011] Such as figure 1 As shown, the anti-static guide mechanism of the insulating paperboard laminator according to the embodiment of the present invention includes a guide frame bottom plate 3, a corner frame 4, and a guide pad 5. The guide frame bottom plate 3 is arranged on the outside of the movable table 1, which The outer end is fixedly connected to the outer frame plate 2 by the hexagon socket screw 8, and the inner end is connected with the corner frame 4, and the lower part of the corner frame 4 is provided with a guide pad 5; the inner corner of the corner frame 4 is passed the hexagon socket screw 6 with spring washers Connected to the movable table 1, a cylindrical pin 7 is arranged between the corner bracket 4 and the movable table 1; four corner brackets 4 are arranged around the movable table 7.

[0012] The above embodiment is one of the more preferred specific embodiments of the present invention, and the usual changes and substitutions made by those skilled in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com