Multirange full automatic high precision pull control system

A tension control and control system technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of a single tension sensor range requirement, more pure manual control, low power accuracy and power consumption requirements of the tension sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

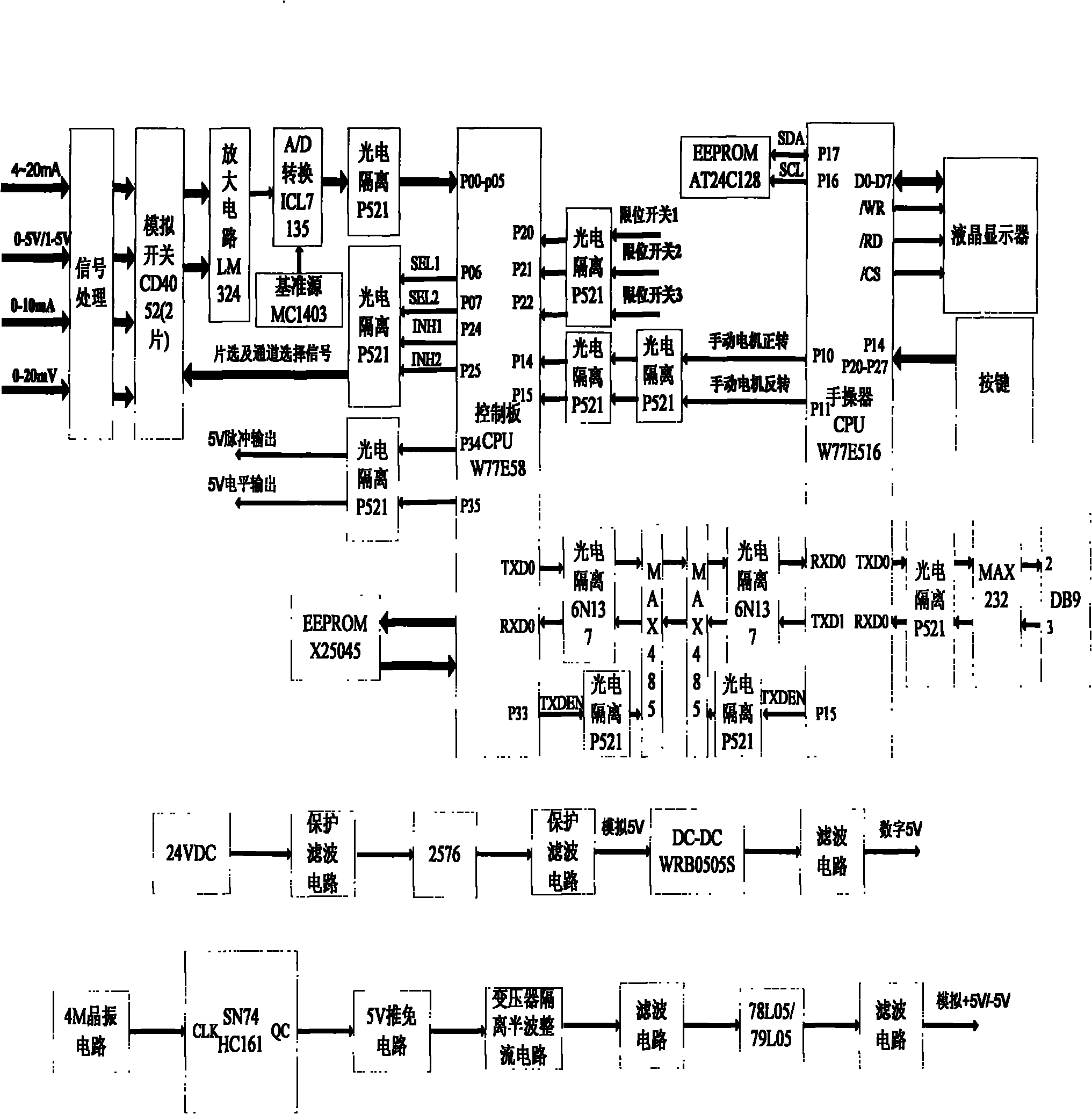

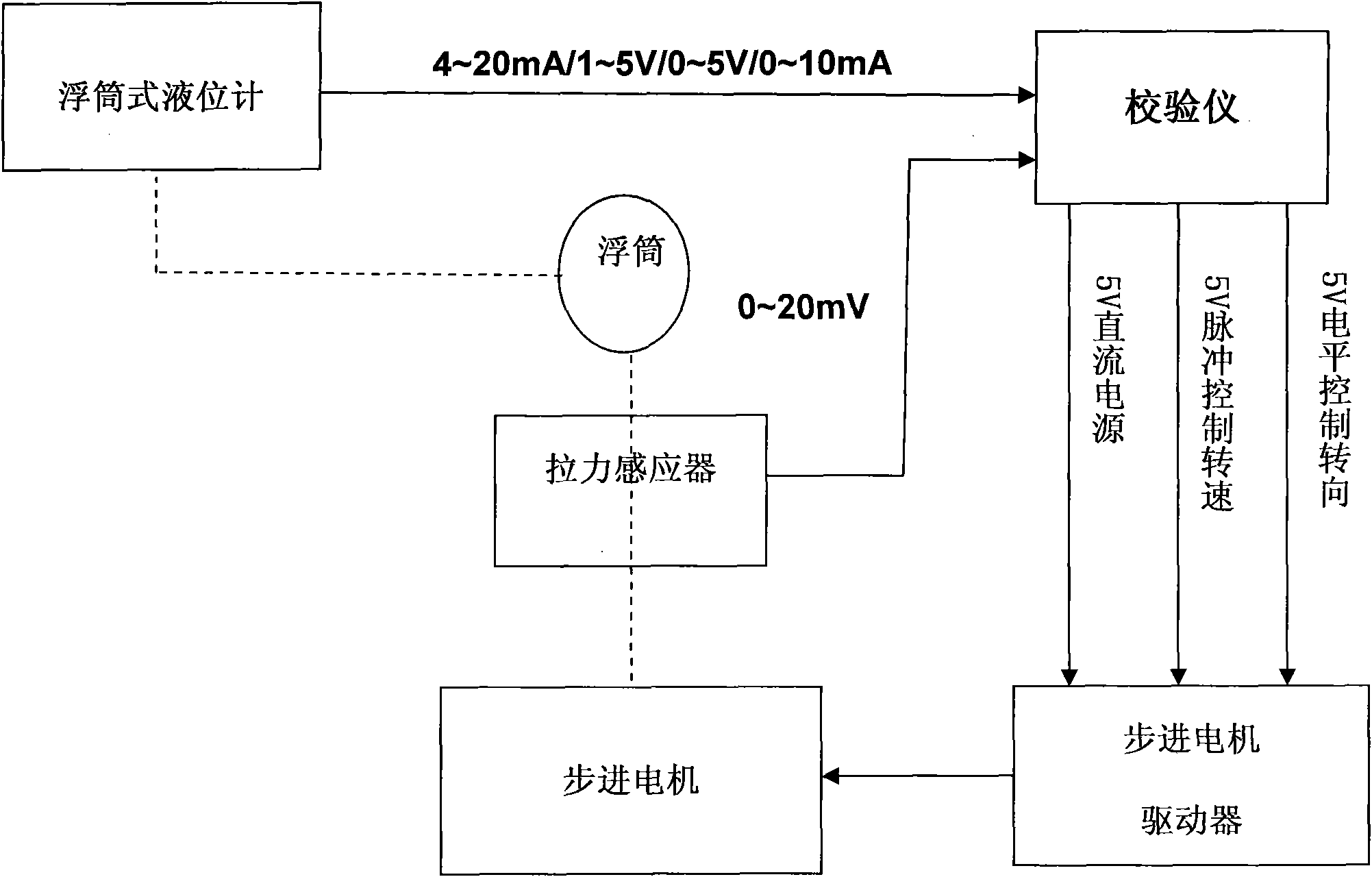

[0019] exist figure 1 Among them, the chip used for A / D conversion is ICL7135, the CPU of the control board is W77E58, and the CPU of the handheld device is WW77E516. The communication between the two units is realized through the RS485 bus connection, and the positive and negative directions of the stepping motor are controlled respectively through two manual lines. Turn, the handheld communicates with the computer through RS232. EEPROM stores calibration and calibration parameters, and the power supply part mainly provides digital and analog isolated 5V voltage for chips and devices and 10V standard power supply for tension sensors. The 9 buttons (UP, DOWN, LEFT, RIGHT, CHECK / SAVE, STOP / DEL, ENT, ESC, MODE) in the handheld operator can realize the corresponding verification operation.

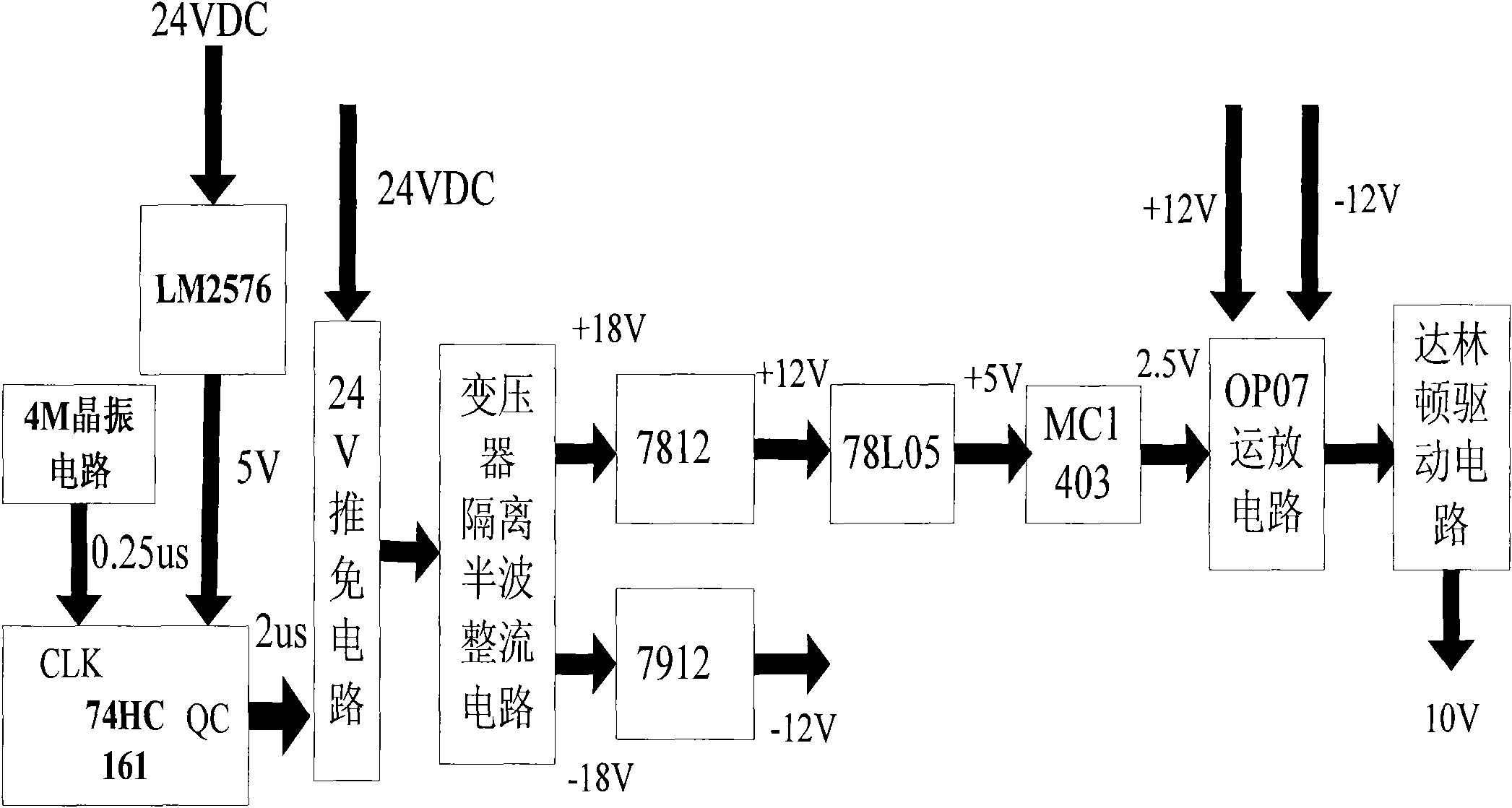

[0020] exist figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com