Drum-type washing and drying machine

A washer-dryer and drum-type technology, which can be applied to other washing machines, household clothes dryers, washing machines with containers, etc., and can solve problems such as overpowering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. It should be pointed out that such examples do not limit the scope of the present invention.

[0053] (Example)

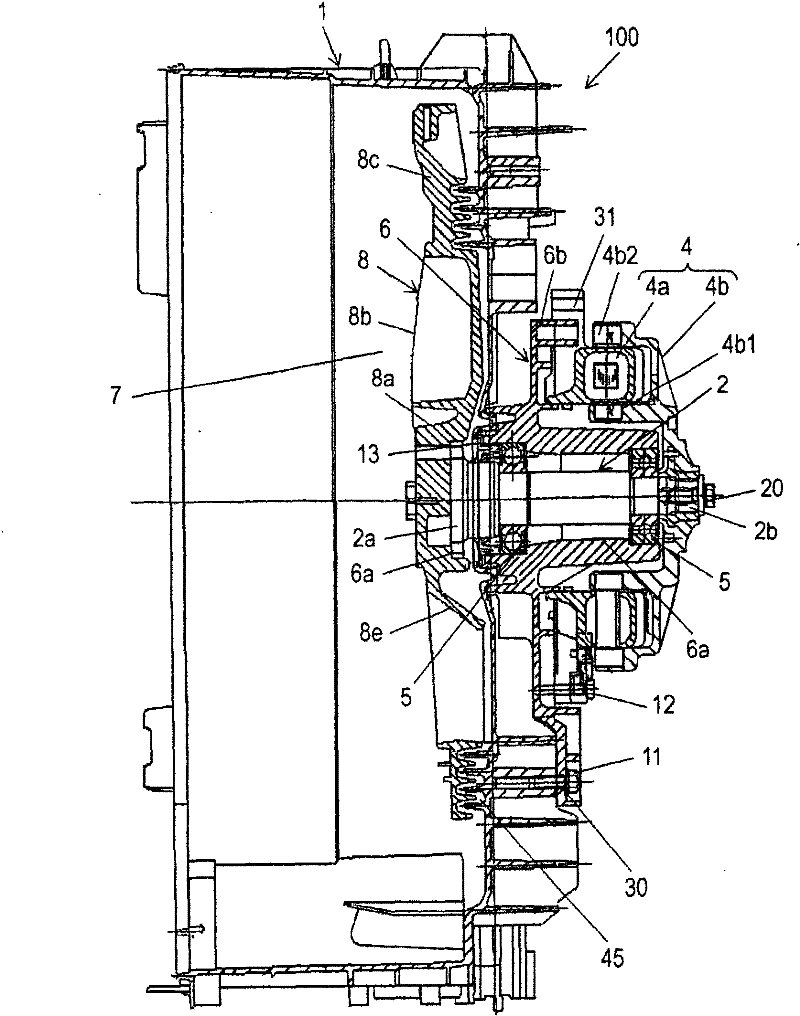

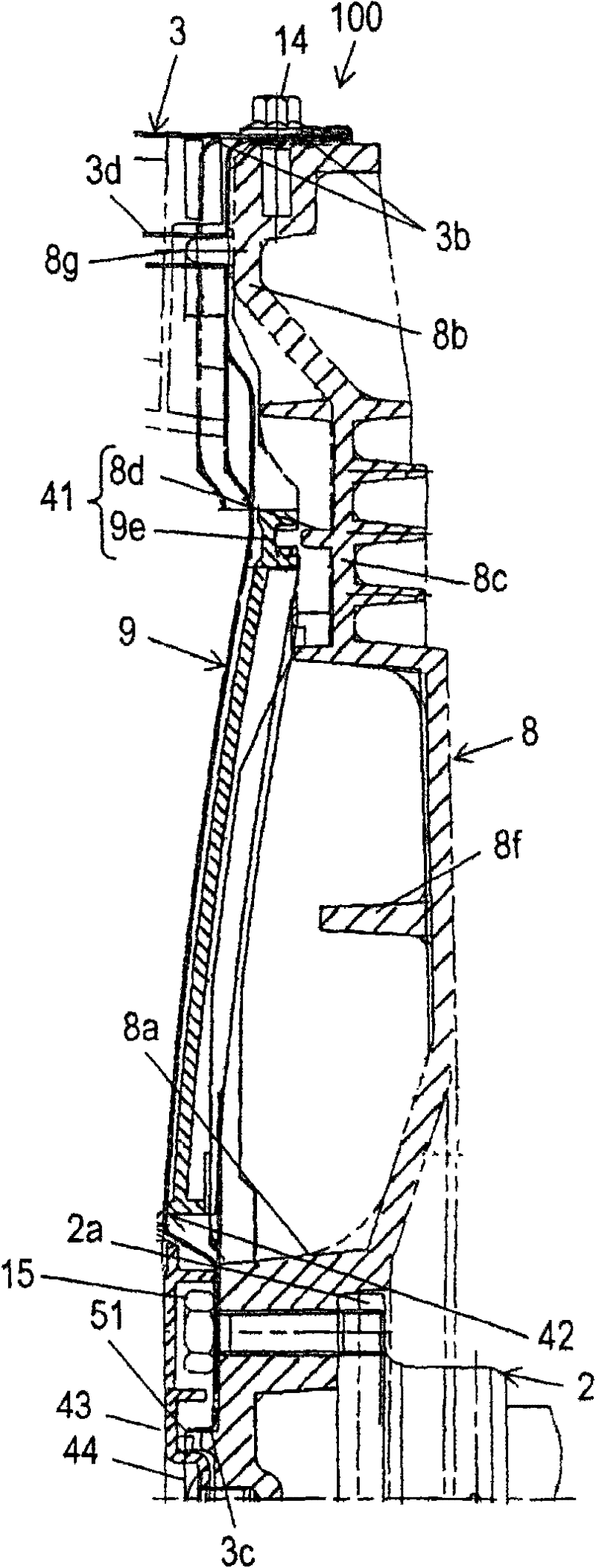

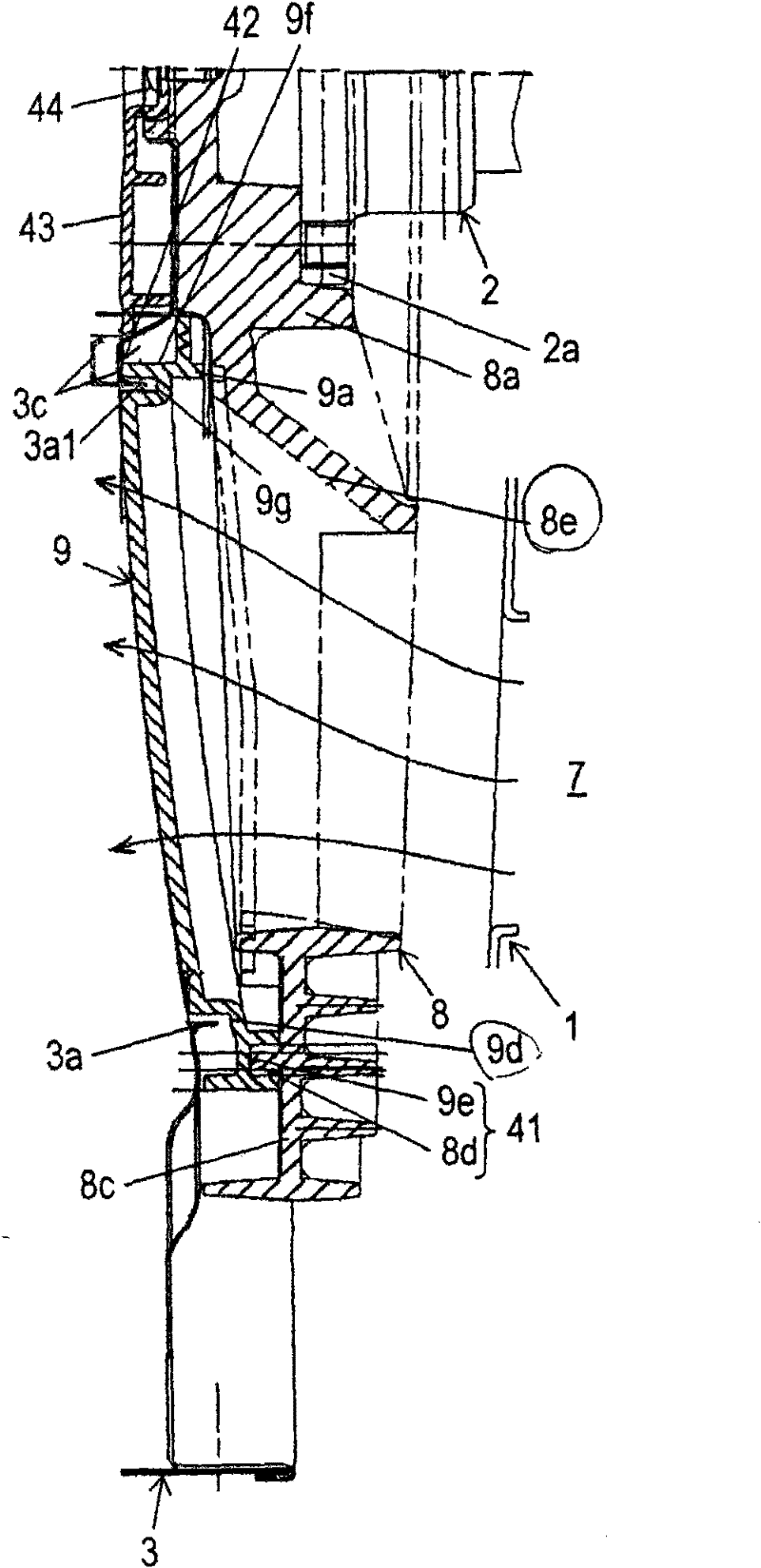

[0054] figure 1 It is a cross-sectional view showing a component that supports a rotating shaft connected to a rotary drum through a shaft connecting support member by a bearing support member in one embodiment of the present invention. Figure 2A It is a cross-sectional view showing the connection components of the rotary drum and the rotary shaft of the drum-type washer-dryer, which are connected by means of the shaft connection support member. Figure 2B is connected Figure 2A Figure below. image 3 It is a rear view showing the main part of the tub of the drum type washer-dryer in the embodiment of the present invention, which supports the rotary drum, attaches the motor to the back of the tub, and connects the rotary shaft. Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com