Fireworks safety firing cable and manufacturing method thereof

A production method and fuse technology, applied in fuzes, offensive equipment, etc., can solve problems such as long process, drug breakage, and large environmental pollution, and achieve the effects of improved production safety, improved product quality, and no dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

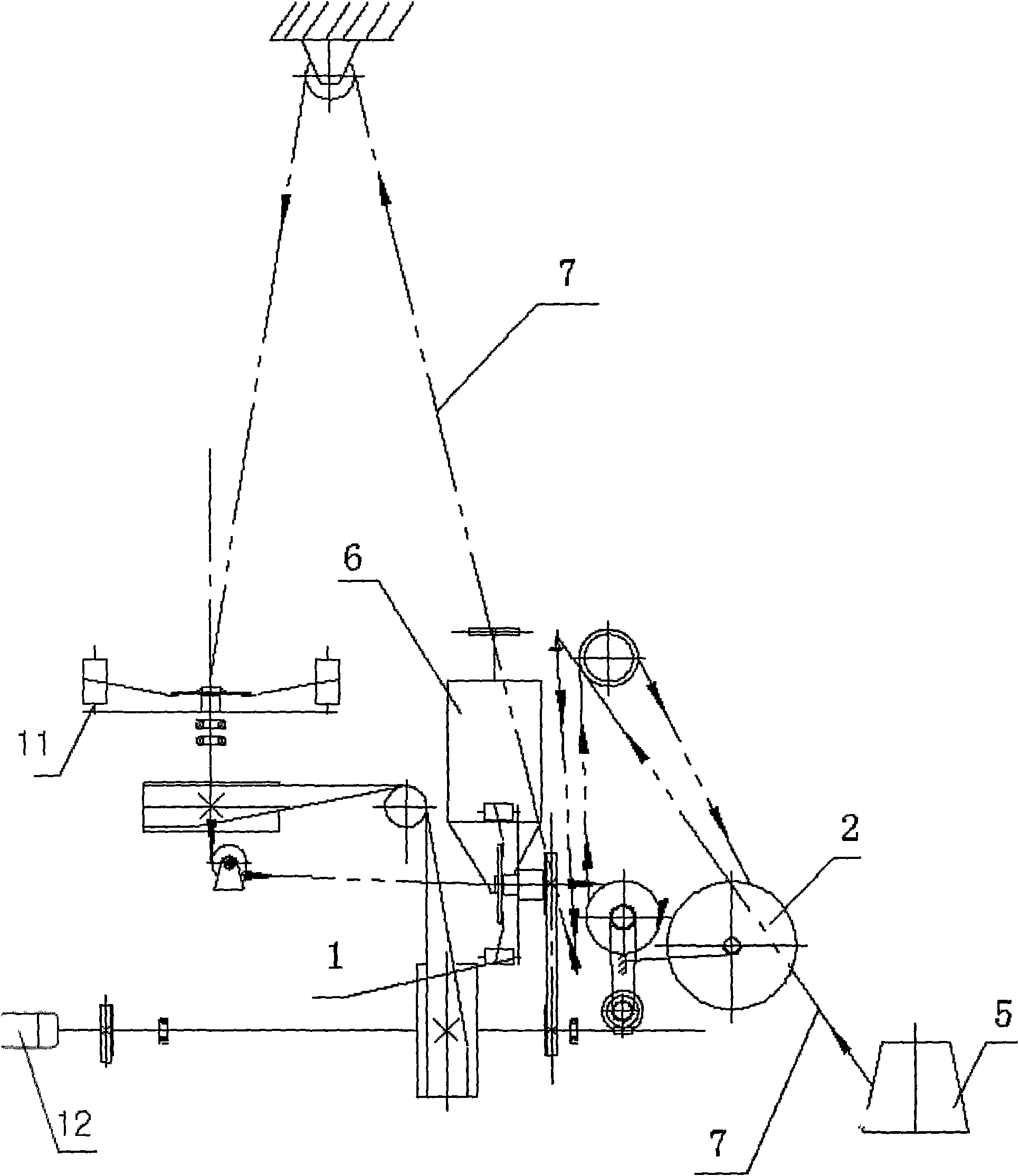

Method used

Image

Examples

Embodiment Construction

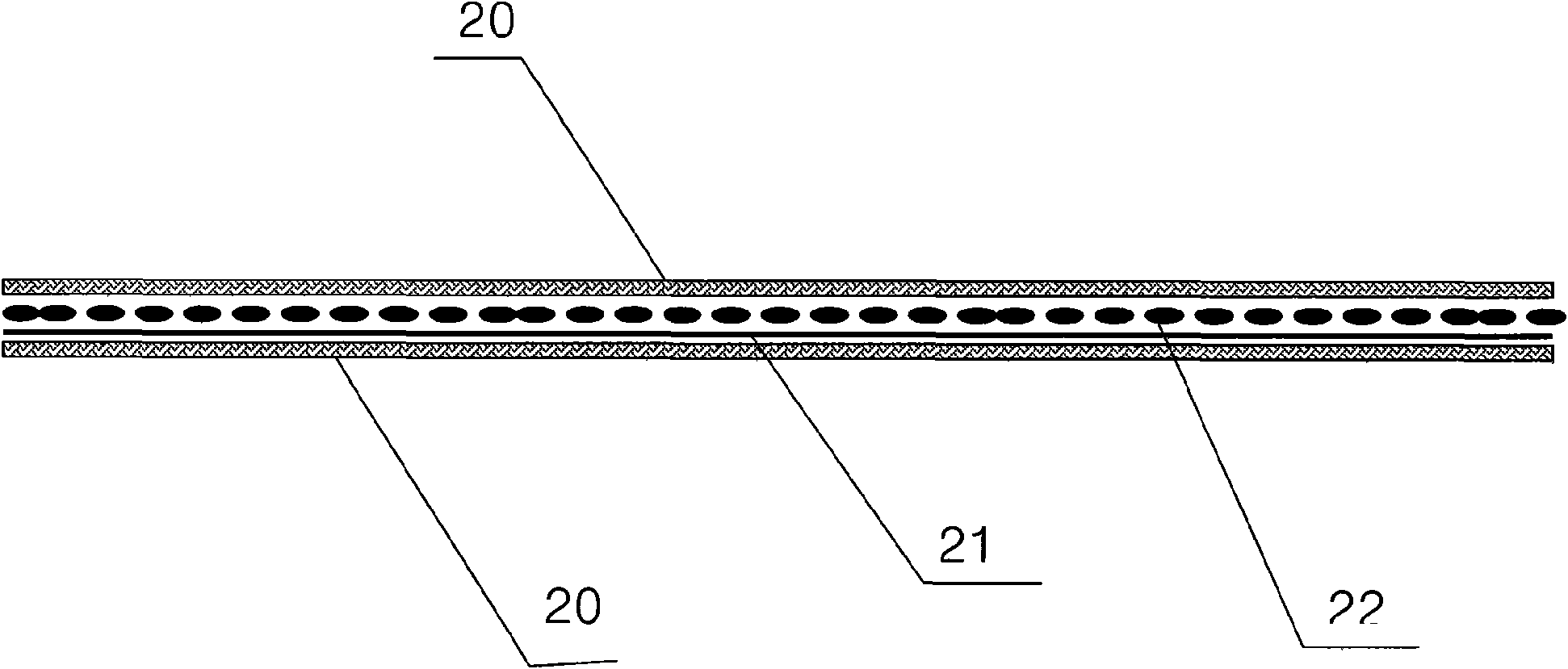

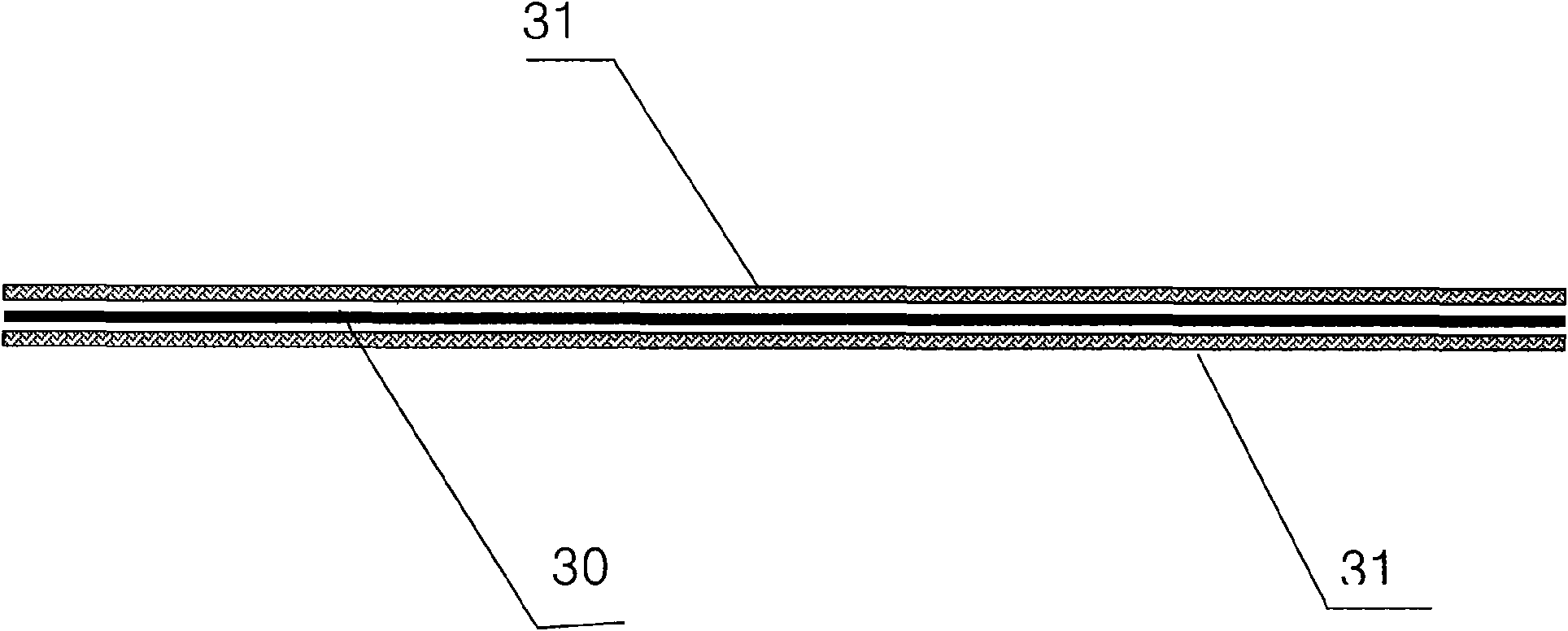

[0039] see figure 2 , the firework safety fuse includes a wrapped sleeve 31 formed by weaving cotton yarn, the sleeve 31 is provided with a waterproof layer, and the sleeve 31 is wrapped with a drug core 30 composed of cotton yarn adhered with fuse medicine .

[0040] The preferred specific manufacturing method of the safety fuse is composed of the following steps in sequence:

[0041] Step 1, fuse drug preparation:

[0042] 1), get rid of the impurities in the medicine and take the medicine according to the following proportioning ratio: 25kg of potassium perchlorate; 7kg of fireworks whistle agent (potassium hydrogen terephthalate); 6kg of charcoal powder (Chinese fir charcoal powder);

[0043] 2), the above-mentioned powdery medicine is repeatedly sieved and mixed evenly;

[0044] 3), add 15kg of alcohol to the above-mentioned medicine and stir evenly, make the medicine into a viscous fluid slurry state, put it into storage for standby;

[0045] As common fireworks raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com