Device for vacuuming away drilled material when drilling with a drill in masonry and similar

A drill bit and drilling technology, which is applied in the direction of drilling/drilling equipment, parts of boring machine/drilling machine, maintenance and safety accessories, etc., and can solve the problem of small collection capacity of the collection chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

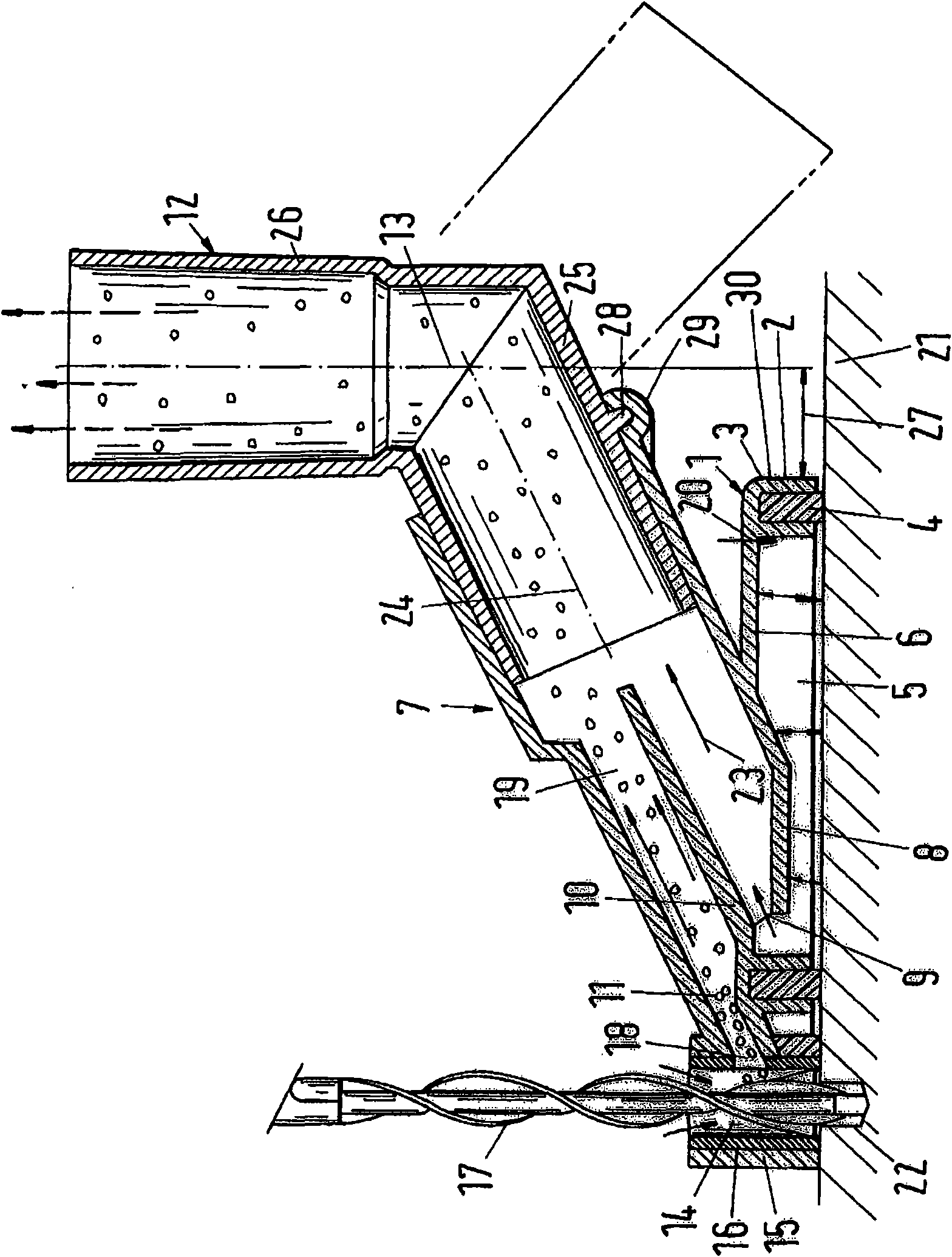

[0021] The suction device is used for suctioning the cuttings which are generated directly at the drilling site during drilling. The device has a base body 1 which can have any desired contour. On a part of the circumference it has a corner 2 bent at right angles, in which a recess 3 for accommodating a seal 4 is arranged. The seal protrudes beyond the edge 2 and surrounds a low-pressure chamber 5 , which is bounded on the peripheral side by the edge 2 with the seal 4 and delimited by the cover 6 of the base body 1 . Projecting into the low-pressure chamber 5 is a tubular connecting sleeve 7 which is advantageously made in one piece with the base body 1 . The connecting sleeve 7 protrudes beyond the base body 1 over most of its length. It projects slightly into the low-pressure chamber 5 with an end region 8 . The end region 8 has an opening 9 through which the low-pressure chamber 5 communicates internally with the connecting sleeve 7 .

[0022] Distributed in the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com