Dust removing device

A technology of dust removal device and dust removal chamber, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve the problems of small dust removal area, polluted environment, dust discharge, etc., so as to reduce labor intensity and reduce dust concentration. , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

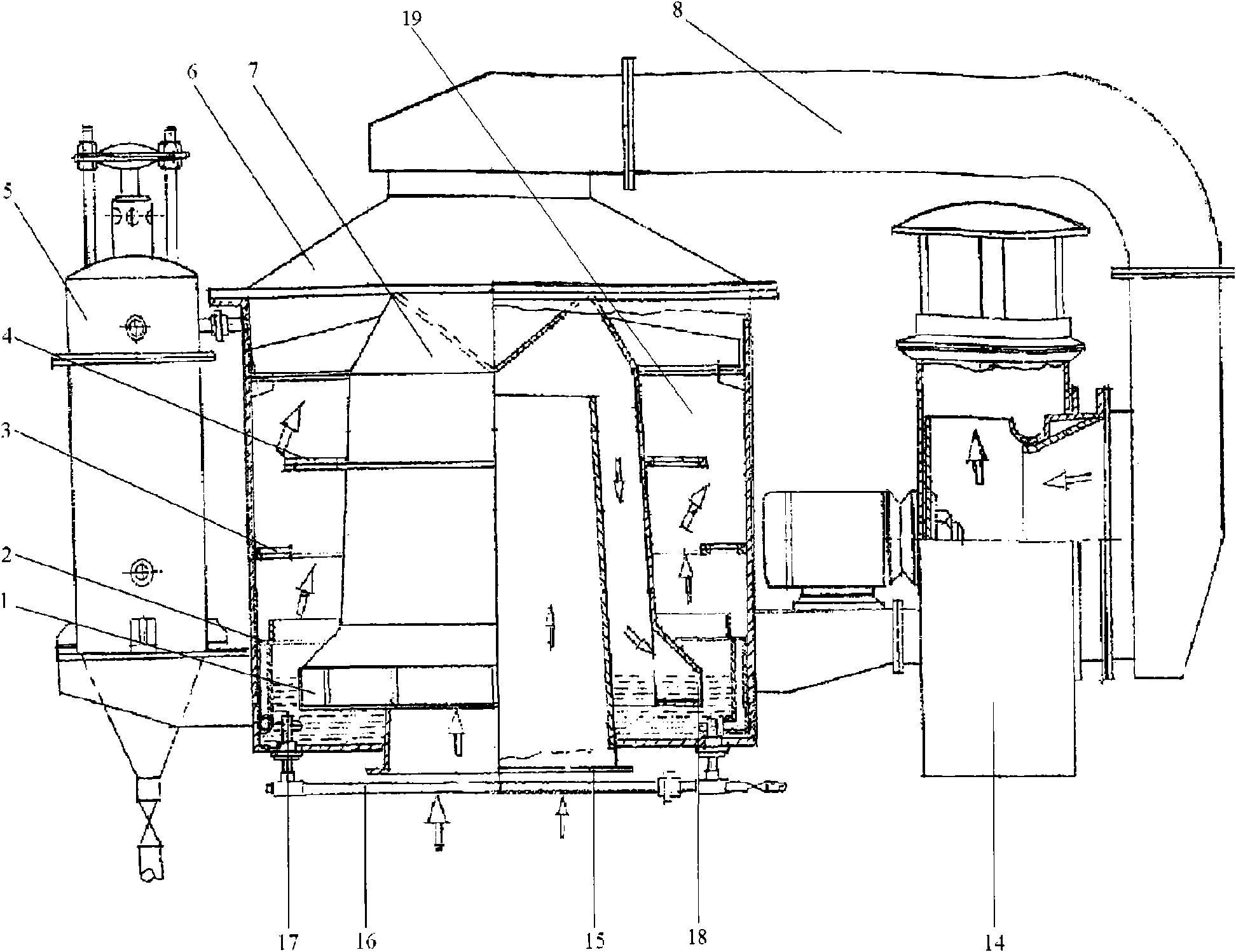

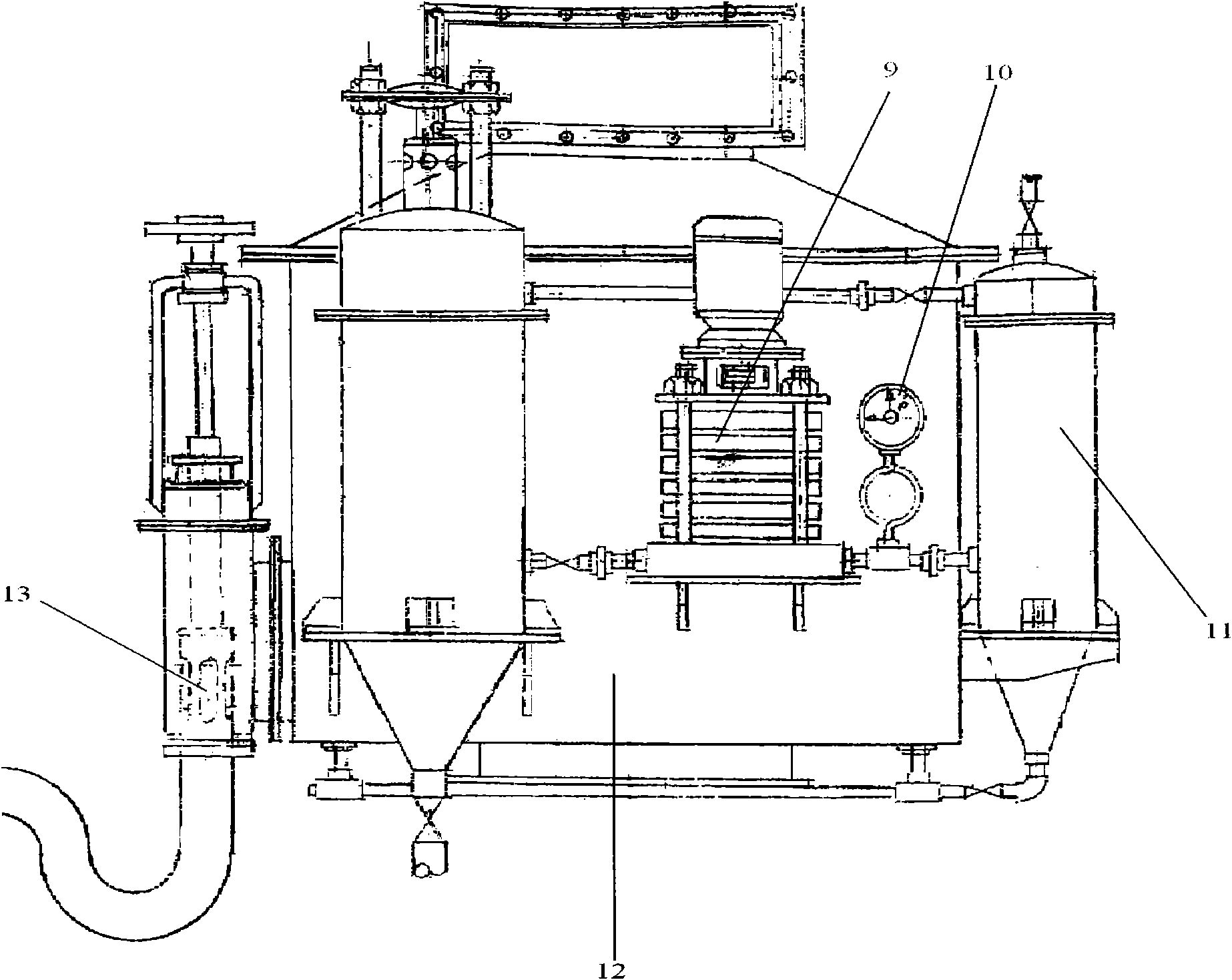

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

[0021] like figure 1 and image 3 As shown, it is the dust removal device of the present invention. The dust removal device includes a mixing dust chamber 7, a fan 14 and a water supply system. The mixing dust chamber 7 is connected with the fan 14 through the air duct pipeline 8 . The mixing and dust removal chamber 7 is a hollow cylinder structure, and a turbine cyclone flow dividing chamber 1 is arranged at the lower end of the cylinder structure, and the upper end of the cylinder structure shrinks slightly toward the middle and is closed. A main dust removal barrel 12 is arranged on the outside of the mixed dust removal chamber 1, and an inner dust suction pipe 15 is arranged at the lower end of the dust removal main barrel 12. The inner dust suction pipe 15 extends toward the inside of the dust removal main barrel 12 to the mixed dust removal. In the chamber 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com