Fuel injector of inner rotor for motor

A technology of injectors and engines, which is applied in the direction of engine components, machines/engines, fuel injection devices, etc., can solve problems such as difficult to completely eliminate fan-shaped blank spaces, poor air and fuel mixing, and affect fuel and air mixing, etc., to achieve Achieve adjustability, improve efficiency and environmental protection, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

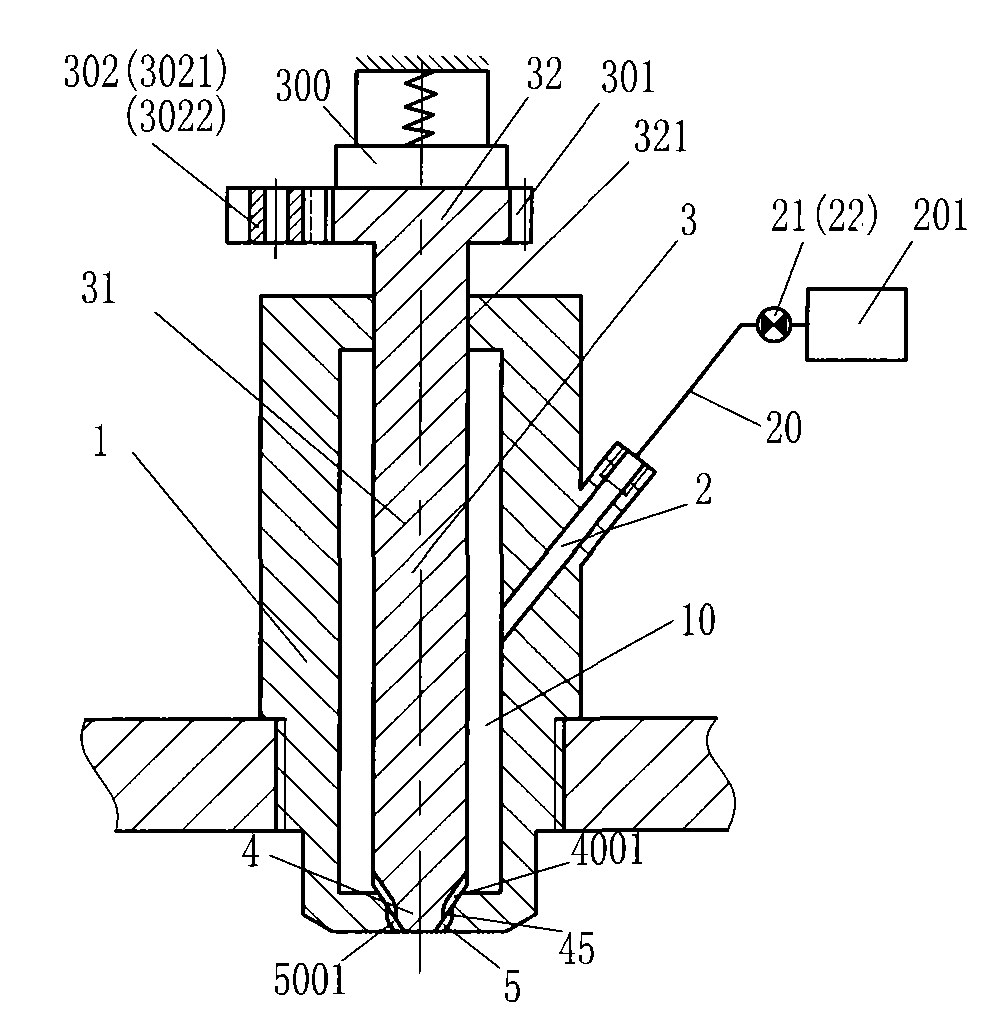

[0075] Such as figure 1 The shown inner rotor fuel injector for the engine includes a fuel injector housing 1 and a valve body 3 arranged in the fuel injector housing 1, and a valve body rotation driving structure 301 is arranged on the valve body 3, The valve body 3 is controlled by the valve body rotation driving device 302 to rotate along the central axis of the valve body 3 via the valve body rotation driving structure 301 .

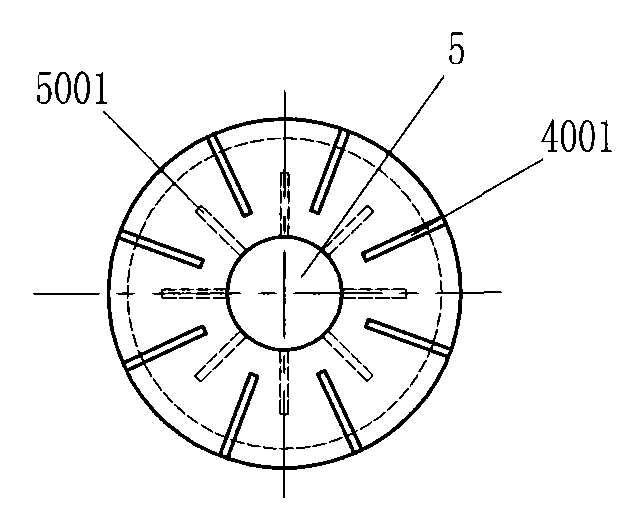

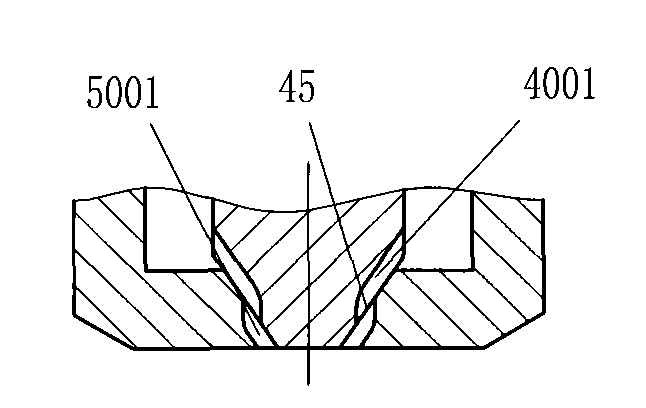

[0076] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 20 In the shown inner rotor fuel injector for the engine, a valve body 3 is provided in the inner cavity 10 of the fuel injector housing 1, and the valve body 3 is composed of a valve head 4, a valve stem 31 and a valve tail 32. One part of the fuel injector housing 1 is in sealing and rotating contact with the valve tail 32 to form a sealing and rotating contact surface 321, and the other part of the fuel injector housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com