Washing device for three-way catalytic converter and inlet channel of automobile and control method

A three-way catalytic converter and cleaning device technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as cylinder blockage, low accident rate, inconvenient cleaning work, etc., to ensure cleaning quality and avoid cylinder lock. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

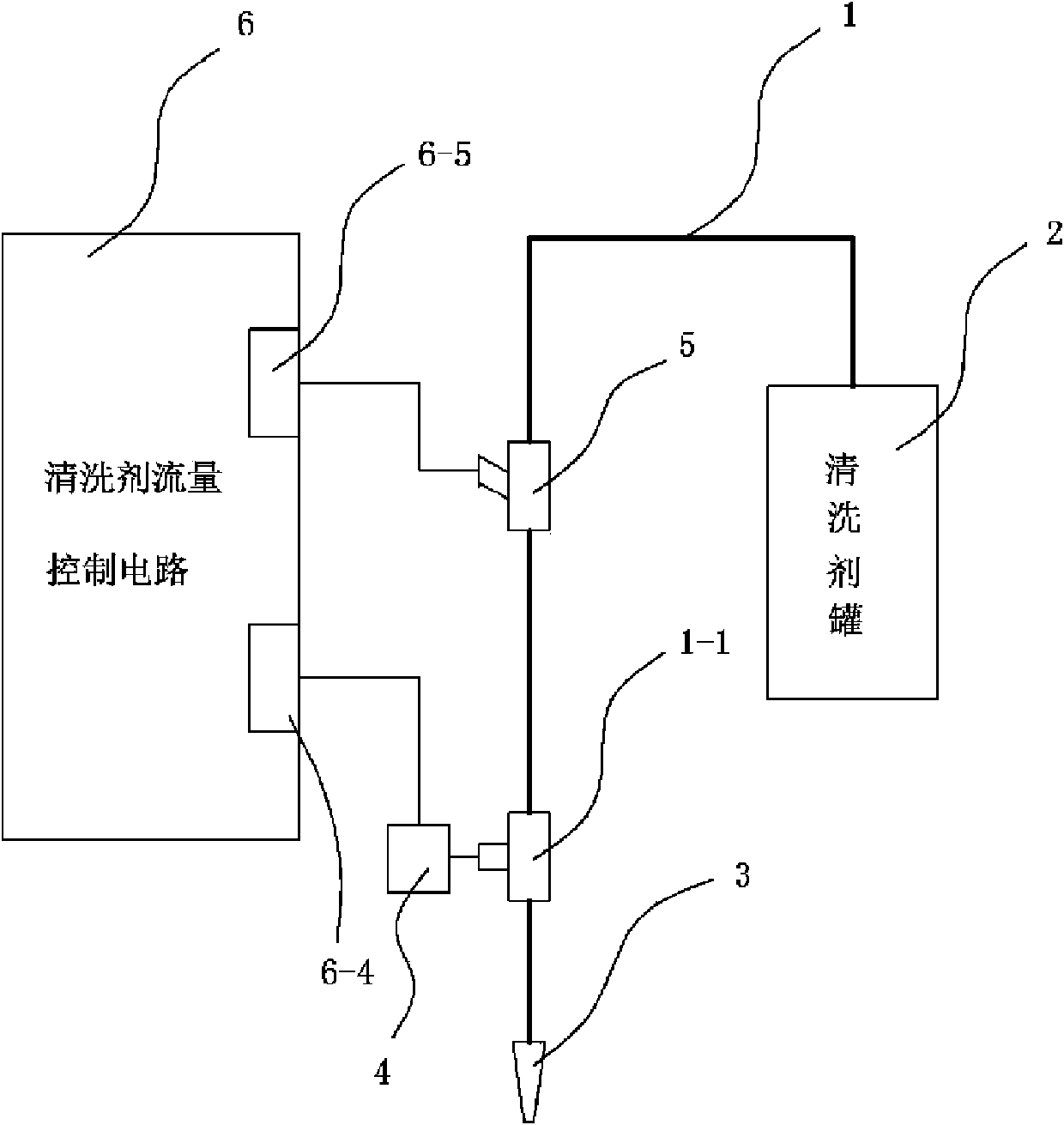

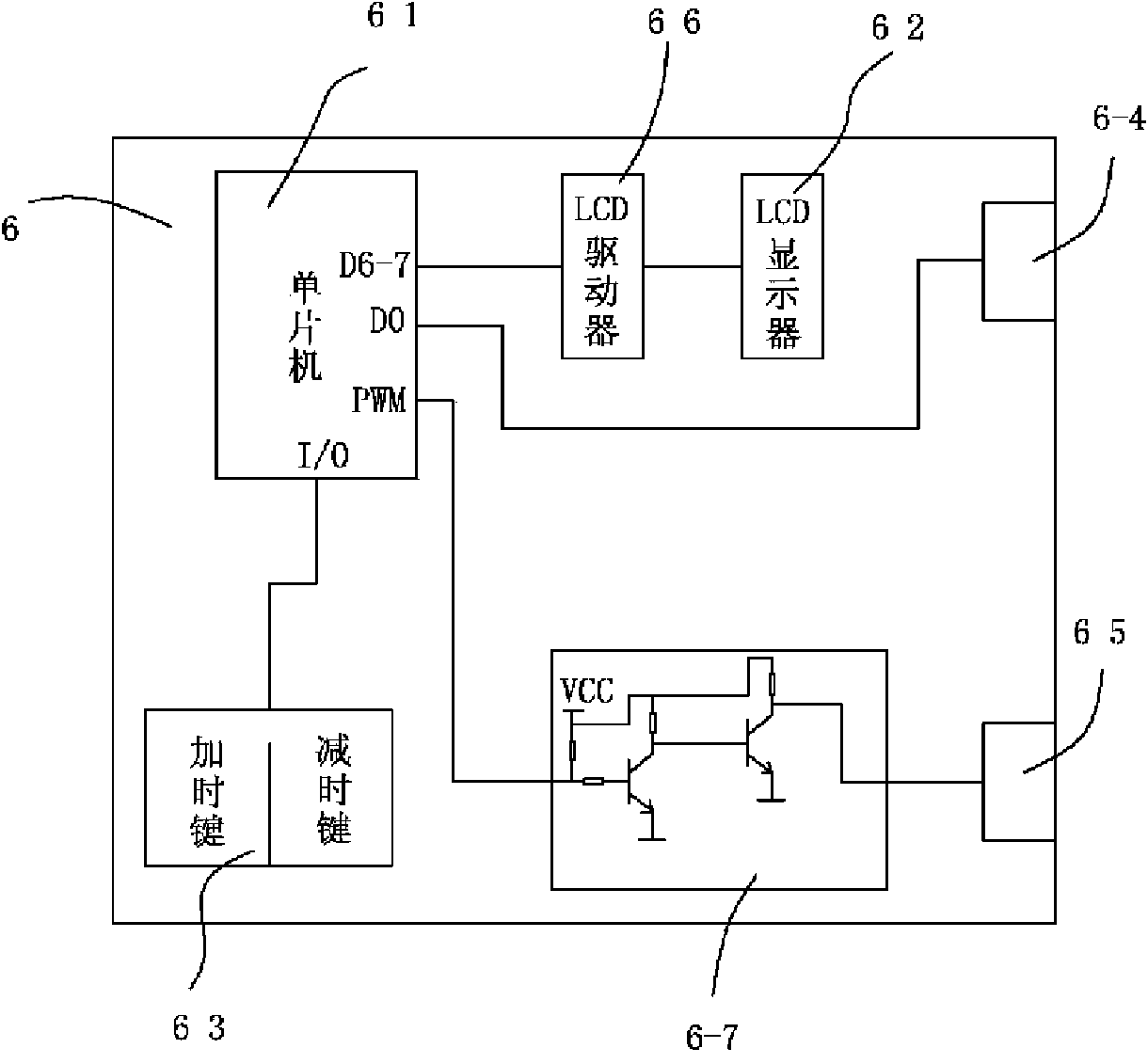

[0021] An example of an automobile three-way catalytic converter and air inlet cleaning device, see figure 1 , The device includes a cleaning agent input pipeline 1, one end of the pipeline is connected to the cleaning agent tank 2, and the other end of the pipeline is the engine vacuum pipeline interface 3, and the engine vacuum pipeline interface from the pipeline to the cleaning agent tank, respectively A vacuum pressure sensor 4 and an electromagnetic flow controller 5 are connected in sequence. The device also includes a cleaning agent flow control circuit 6 in which a vacuum pressure measurement interface 6-4 and an electromagnetic flow control interface 6-5 are provided. The point output signal of the vacuum pressure sensor is connected to the vacuum pressure measurement interface, and the electromagnetic flow control interface is connected to the electrical signal control input end of the electromagnetic flow controller.

[0022] The vacuum pressure sensor in the embodimen...

Embodiment 2

[0028] An embodiment of an automobile three-way catalyst and air intake cleaning control method, see embodiment 1 and image 3 , Based on a three-way catalytic converter and intake port cleaning device for an automobile described in Example 1; the three-way catalytic converter and intake port cleaning control method are:

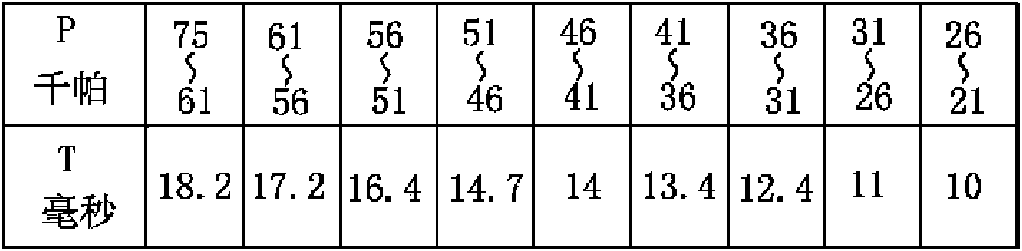

[0029] First, set an interval between the maximum pressure value and the minimum pressure value of the vacuum pressure. In the interval, the electromagnetic flow controller is in the open time when the flow rate is 13.5 g ± 0.5 g / min. The electromagnetic flow controller is not in the interval Off state; store the above-mentioned vacuum maximum pressure and minimum pressure and the corresponding flow state open time data in the memory of the cleaning agent flow control circuit, where the open flow is 13.5 g ± 0.5 / min state corresponding to electromagnetic flow control Connect the engine vacuum pipeline interface of the pipeline to the automobile vacuum pipeline t...

Embodiment 3

[0044] An improved embodiment of an automobile three-way catalytic converter and air inlet cleaning control method. See Example 2. The difference from Example 2 is that the maximum vacuum pressure is 61 kilopascals (KPa) and the minimum vacuum pressure is It is 20 kilopascals (KPa).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com