Device and method for removing flat print products from a pile and transferring the print products to a running transport device

A technology for printing products and conveying devices, which is applied in the field of equipment and methods for removing printed products from stacking and transferring them to conveying devices, can solve problems such as increased self-weight of printed products, height limitation of stacking boxes, and inability to use bars and so on. , to achieve the effect of low throwing height, reducing process risk and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

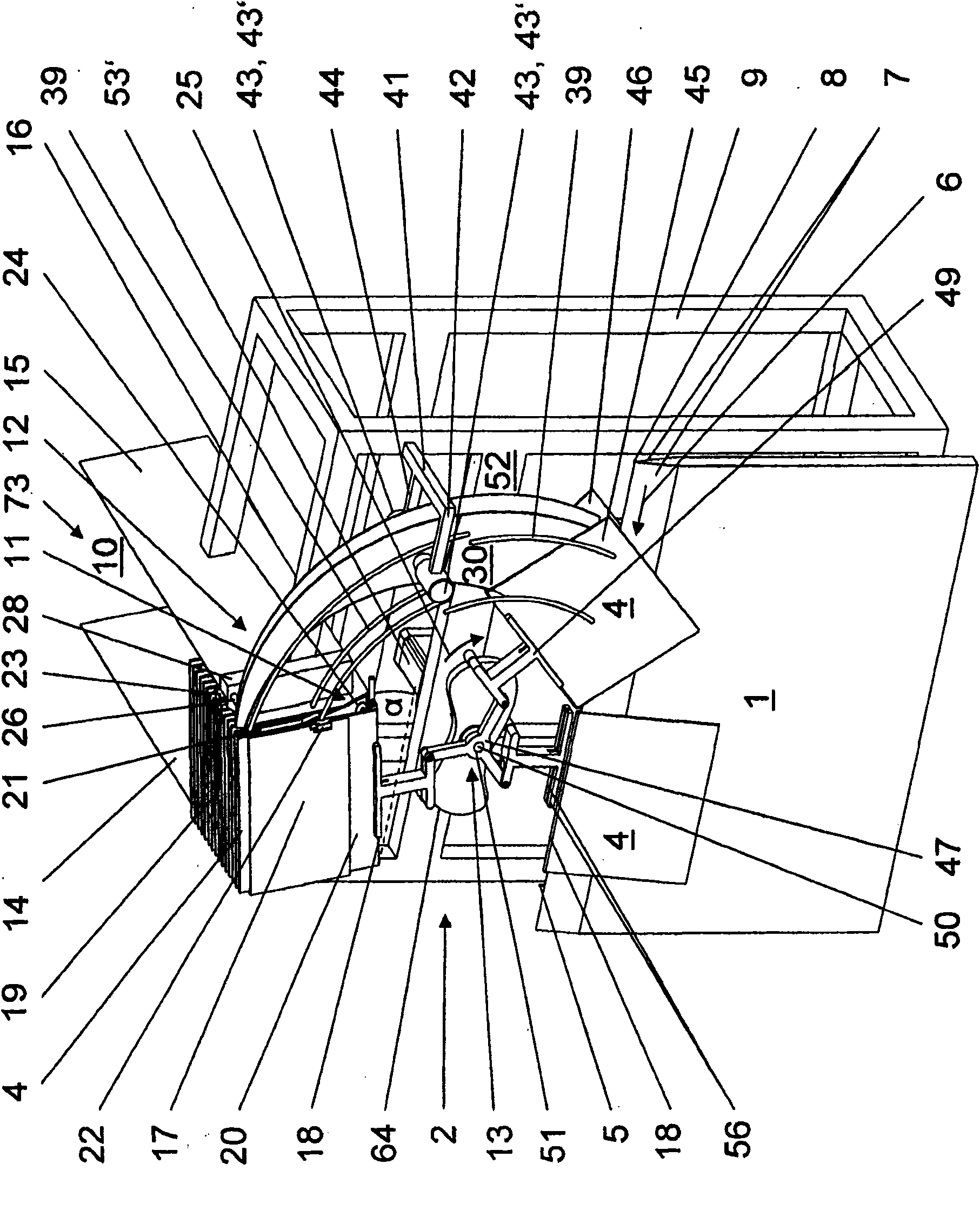

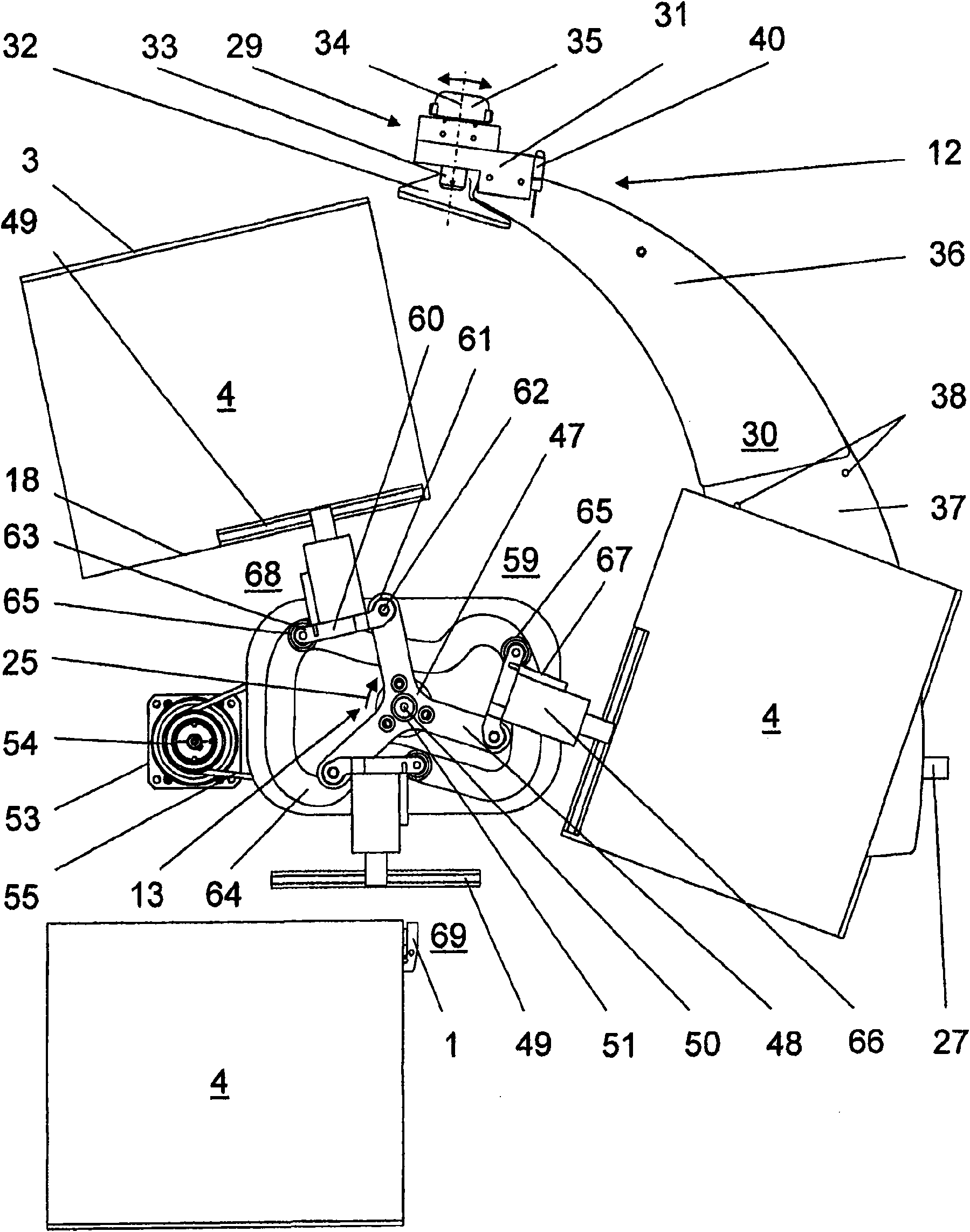

[0028] figure 1 Shown is a conveyor device 1 configured as a collection chain (Sammelkette), provided with a spine groove, of a known leaf binding machine (Sammelhefter) not shown in detail 3( figure 2 ), designed as a flat printed product 4 in the form of a folded printed sheet signature, is placed between two adjacent clips (Mitnehmer) 5 via the feeder (Anleger) 2 with the transport device, and There it is conveyed further along the conveying direction 6 . For this purpose, the conveyor device 1 has two support plates 7 which ride on top ends 8 in a saddle-like manner. Of course, this solution is not limited to the conveying device 1 configured as a collection chain of a saddle stitching machine. , the combination of the collation groove of the inserter, or the combination with a suitable conveyor belt. It goes without saying that unfolded printed individual signatures can also be processed.

[0029] The paper feeder 2 carried by the support 9 has a book table (Magazi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com