Pouch for a pressurized bottle

A technology of bags and tubular walls, which can be used in liquid distribution, packaging, distribution devices, etc., and can solve problems such as blocking bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

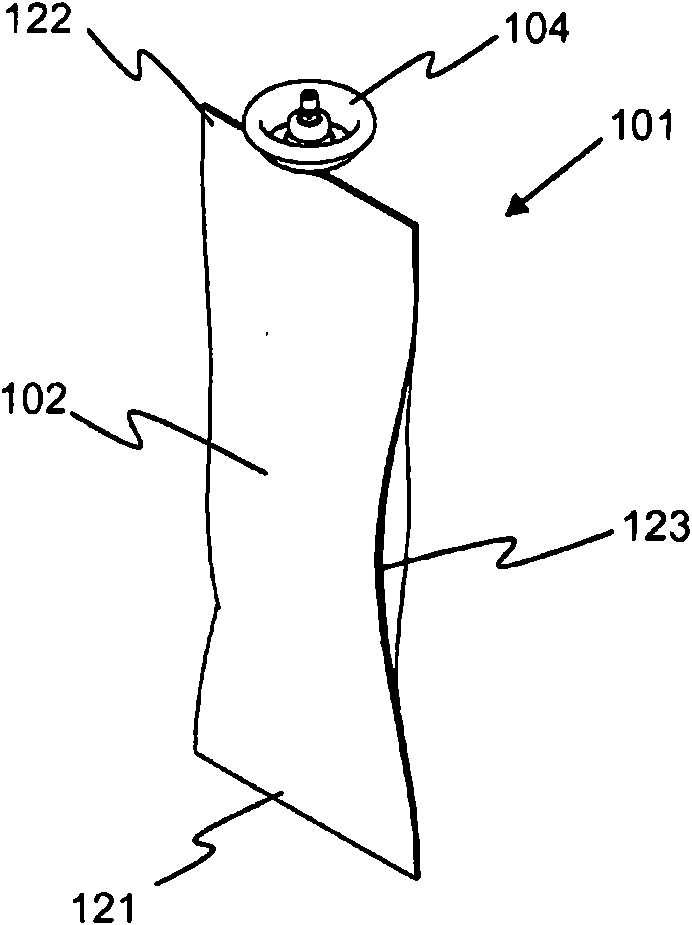

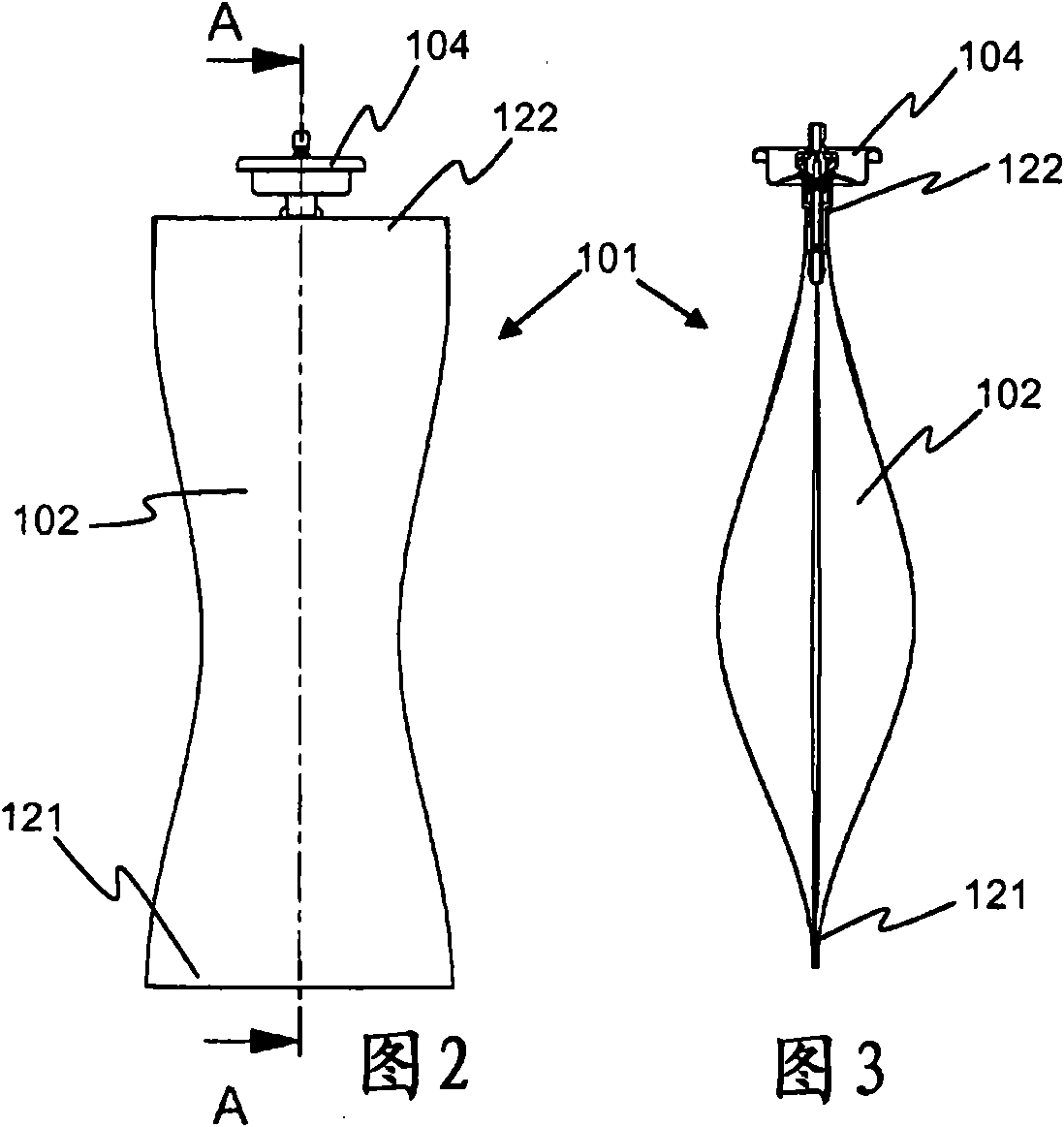

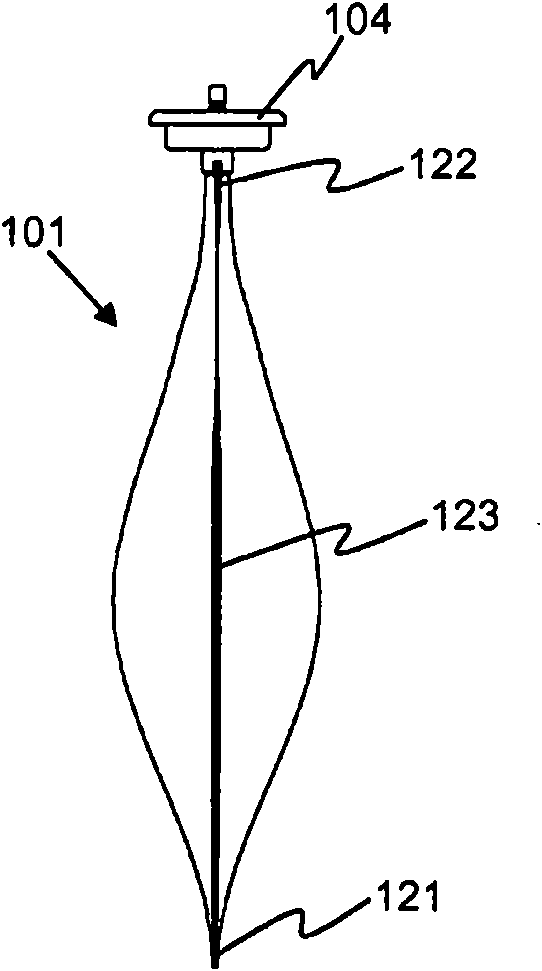

[0024] [24] In both embodiments, the bag body 1 , 101 of the present invention is composed of a tubular wall 2 , 102 . The tubular wall is obtained by welding two sides of a body, wherein the two sides overlap each other. The longitudinal weld 23 , 123 is thus formed by affixing the inner surface of one of the sides to the outer surface of the other side of the strip. This longitudinal weld is thus located in the extension of the tubular wall and is not protruding as is the case in the prior art in which the two edges are welded by placing the inner surfaces of the edge portions of the strip facing each other.

[0025] [25] The tubular wall 2 , 102 consists of a strip closed to itself, for example by a weld seam, so that a circular cross-section without beading edges is obtained.

[0026] [26] The upper end 22, 122 is closed by flattening the tubular wall and welding the tubular wall to itself. An aerosol valve 4 , 104 known per se is provided in the center of this weld 22 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com