Corner tube boiler adopting uniform scouring convection tube bundle

A technology of convective tube bundles and corner tubes, applied in steam boilers, fluid heaters, steam generation, etc., can solve the problem of high smoke velocity at high temperature end, improve heat transfer coefficient and heat transfer efficiency, improve economic benefits and reliability , the effect of wear reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

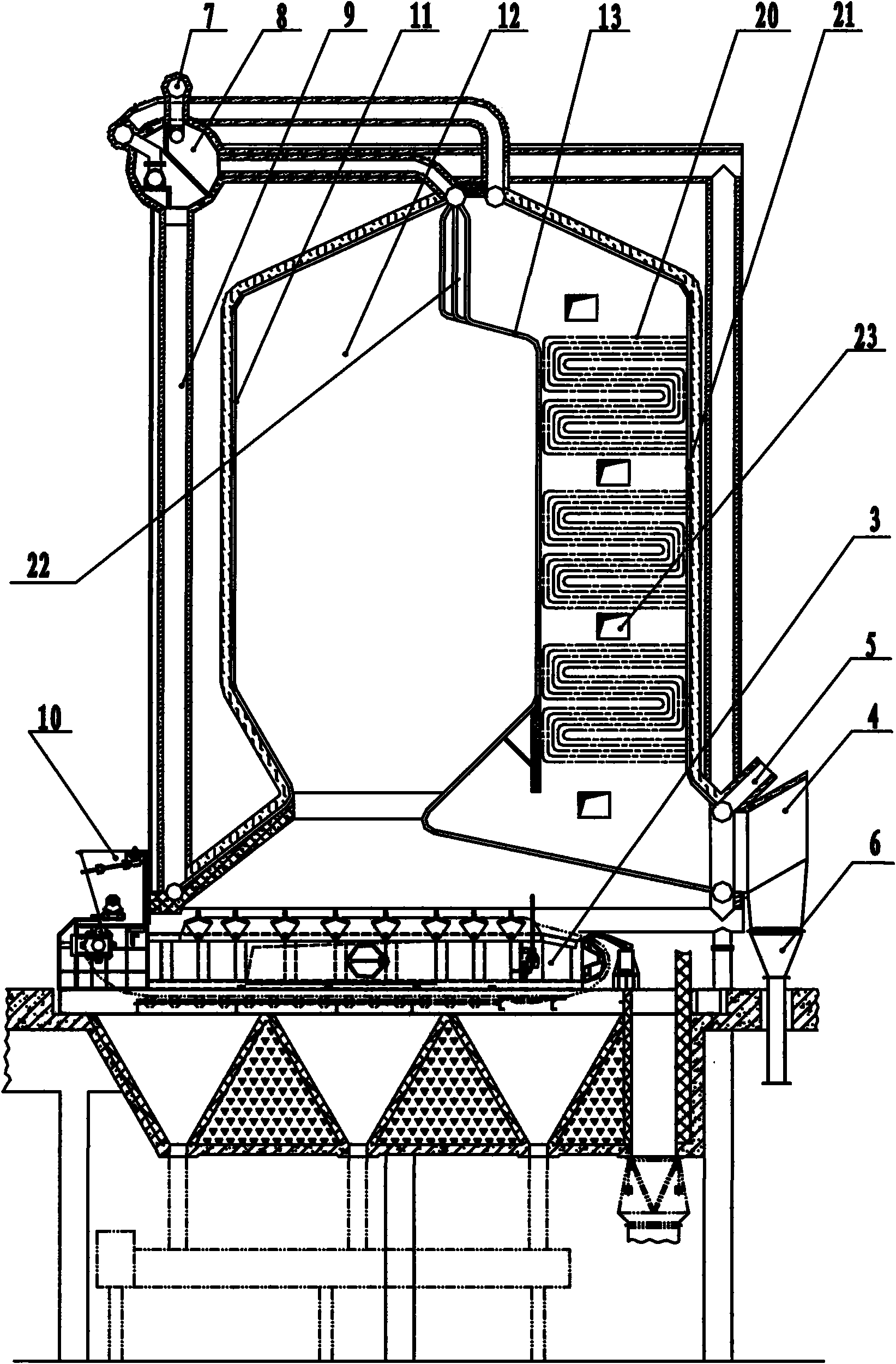

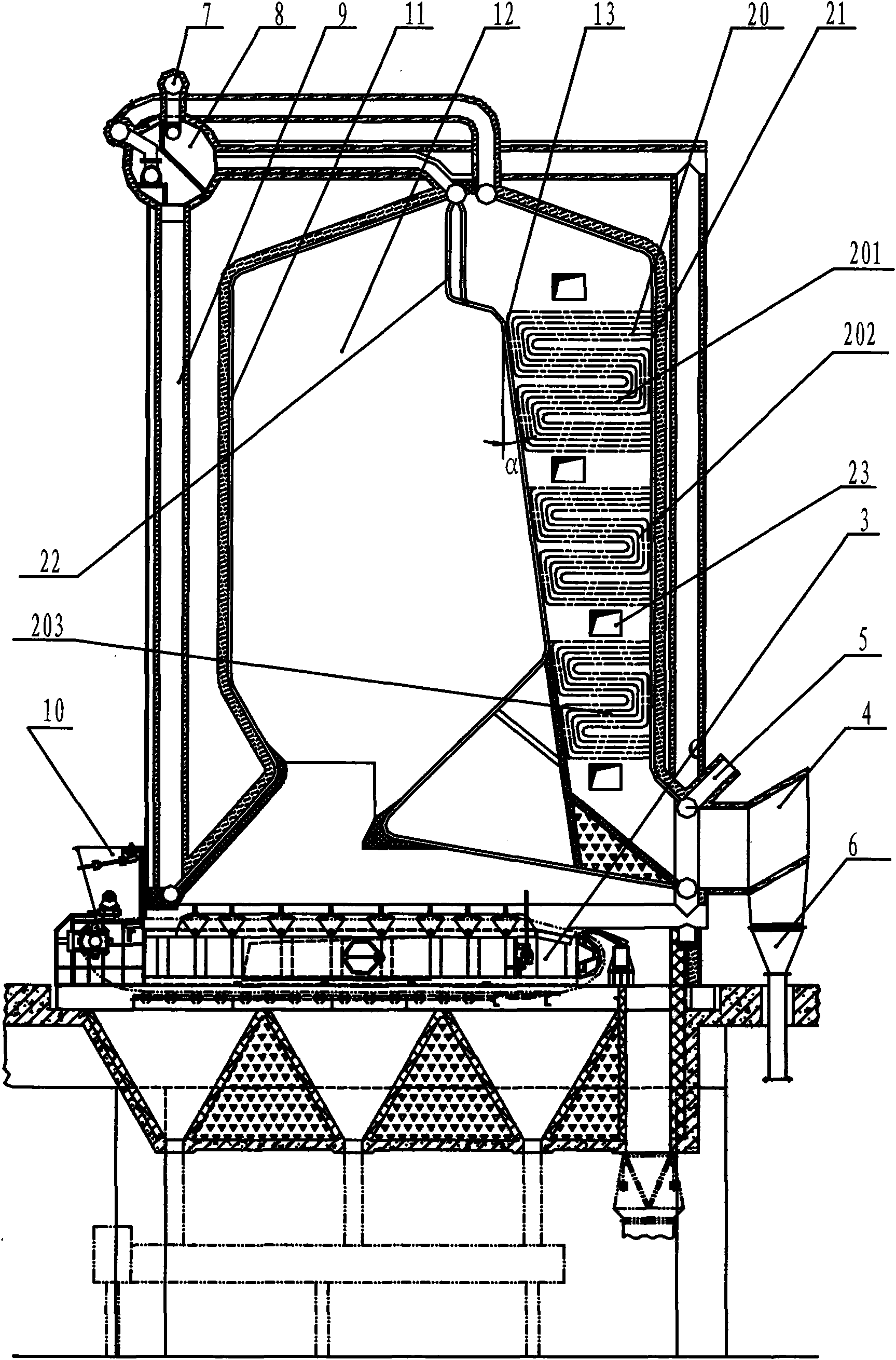

[0015] see figure 1 , the corner tube boiler in the prior art has a ∏-shaped structure as a whole, with the furnace 1 on the left and the tail flue 2 on the right, with the furnace rear wall 13 in the middle as the interface between the furnace 1 and the tail flue 2, The furnace 1 is formed by the furnace front wall 11, the side wall 12 and the furnace rear wall 13, and the tail flue 2 is formed by the furnace rear wall 13, the side wall 12 and the flue rear wall 21, wherein,

[0016] A fire grate 3 is provided at the bottom of the furnace 1; a number of convection tube bundles 20 are arranged at intervals from top to bottom in the tail flue 2, and an observation window 23 is arranged on the side wall 12 of the tail flue 2 to stagger the convection tube bundles 20; the tail flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com