Needle thread feeding device for multi-needle embroidery sewing machine

A feeding device and sewing machine technology, applied in the direction of sewing machine metering device, sewing machine components, embroidery machine mechanism, etc., can solve the problems of detrimental embroidery pattern style, complex structure of sewing machine head, and time-consuming threading, etc., to improve quality and style , Eliminate winding defects, reduce the number of rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

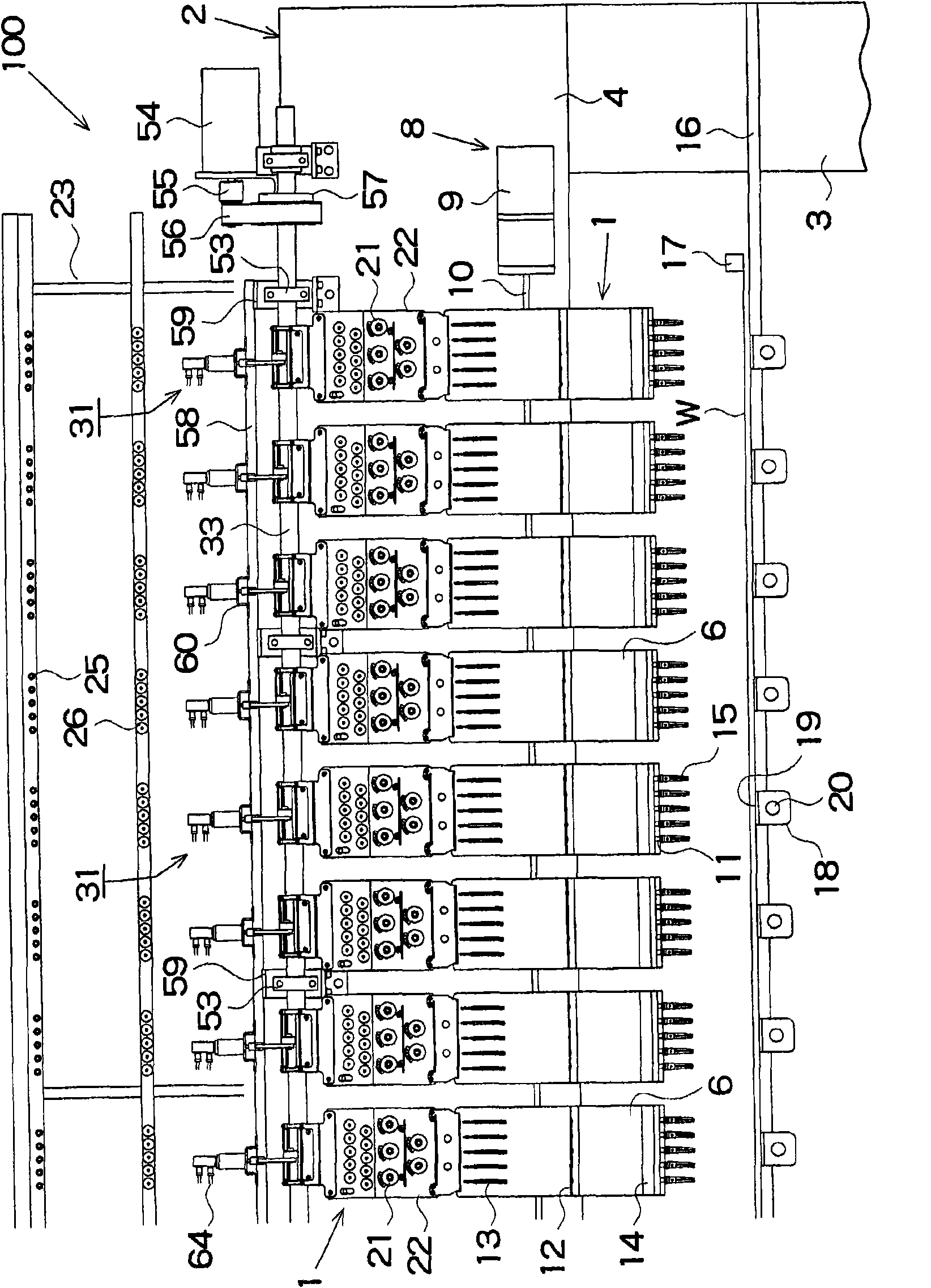

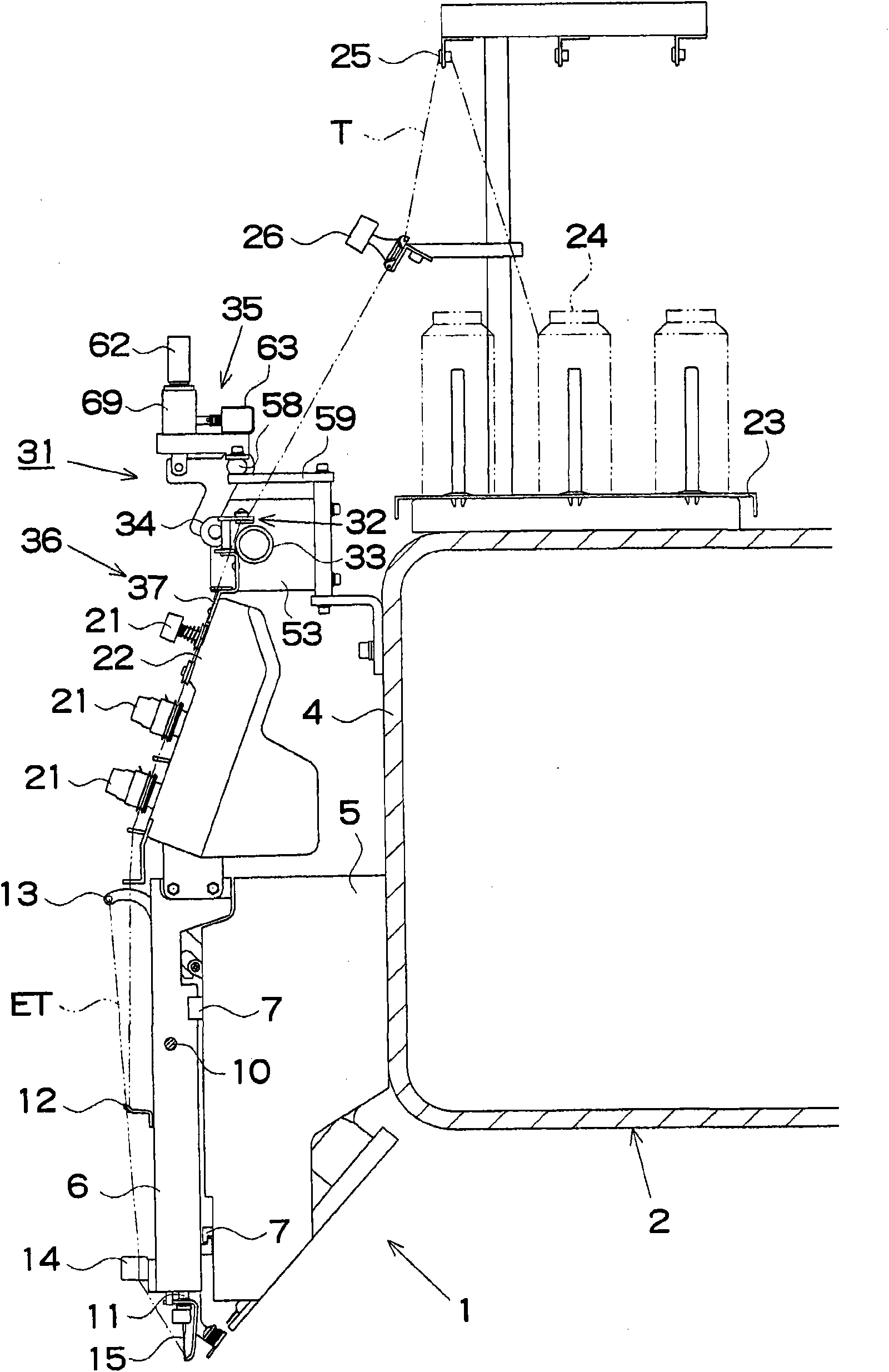

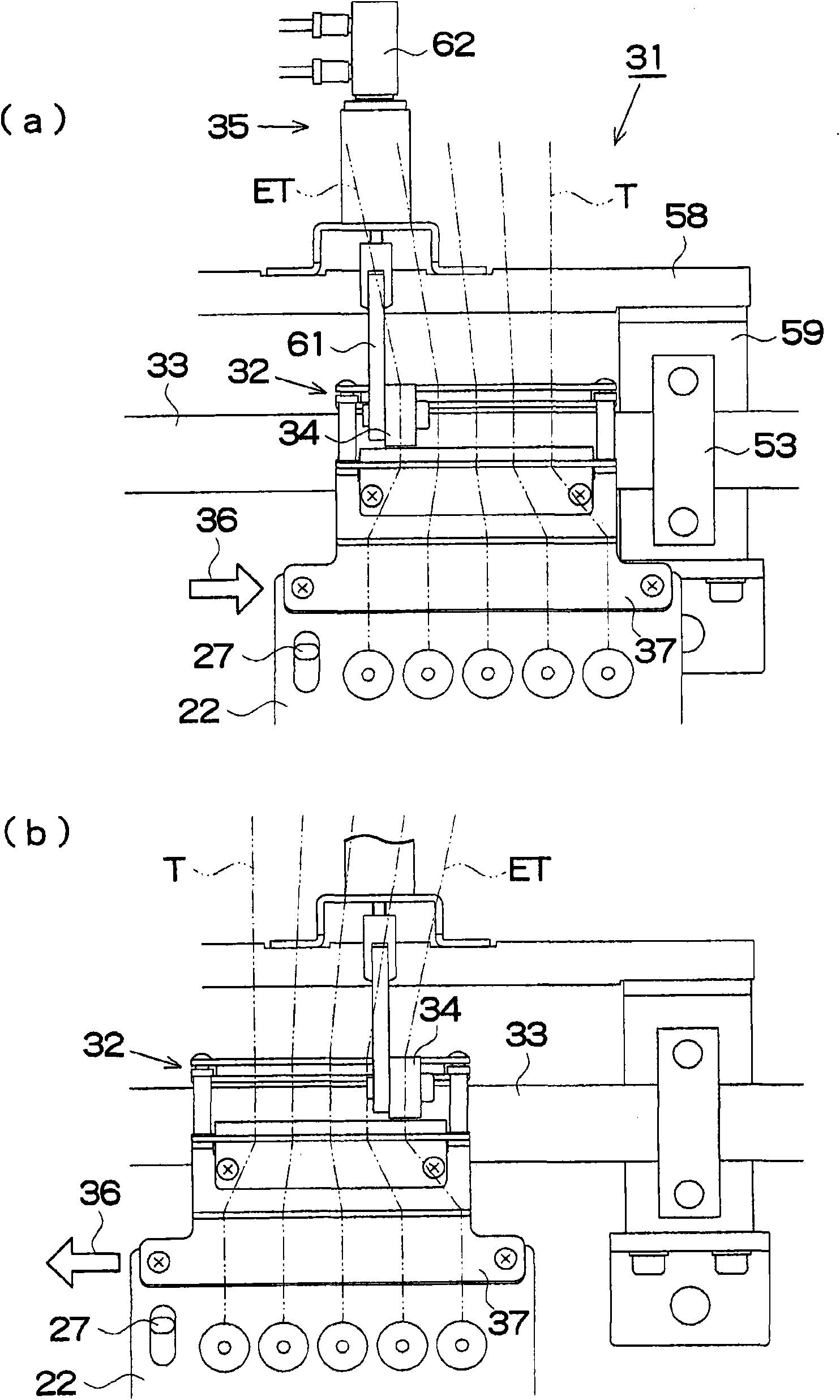

[0014] Below, according to Figure 1~Figure 8 , Describe Embodiment 1 of the present invention. Such as figure 1 , figure 2 As shown, the multi-head embroidery sewing machine 100 of this embodiment is constructed by arranging a plurality of (for example, 56) multi-needle embroidery sewing machines 1 in the left-right direction of the machine frame 2. The sewing machine frame 2 includes a pillar portion 3 and a beam portion 4, and an arm 5 of the multi-needle embroidery sewing machine 1 is provided protruding in front of the beam portion 4. On the front of the sewing machine arm 5, the sewing machine head 6 is slidably supported by a rail 7 in the left-right direction, and all the heads 6 of the embroidery sewing machine 1 are driven by the motor 9 of the color changing mechanism 8 via the connecting rod 10 at one time.

[0015]A plurality of (for example, five) needle bars 11, a thread guide 12, a thread take-up 13 and a thread clamp 14 are arranged on the sewing machine head 6,...

Embodiment 2

[0034] Then, according to Figure 9~Figure 11 , Describe the second embodiment of the present invention. The upper thread feeding device 81 of embodiment 2, such as Picture 9 , Picture 10 As shown, the upper thread guide mechanism 82 and the driving roller 83 are arranged on the beam portion 4 of the sewing machine frame 2, and the pressing roller 84 is movably provided relative to the beam portion 4, and the wiring mechanism 86 presses against the upper thread guide mechanism 82 The roller 84 and the switching mechanism 35 are configured to move in the axial direction of the driving roller 83. Next, a configuration different from that of the first embodiment will be described. In the figure, the same reference numerals as in the first embodiment indicate the components already described.

[0035] Such as Picture 10 , Picture 11 As shown, the upper thread guide mechanism 82 is provided with two thread guides 87 and 88 opposed vertically at approximately the same interval as th...

Embodiment 3

[0038] Then, according to Figure 12 ~ Figure 14 , Describe the third embodiment of the present invention. The third embodiment and the first embodiment are different from each other in that the tensioning table 22 is not provided, and in that a different upper thread feeding device 109 is provided instead of the upper thread feeding device 31 of the first embodiment. Next, the difference between this other upper thread feeding device 109 and the upper thread feeding device 31 of the first embodiment will be described. In the figure, the same reference numerals as in the first embodiment indicate the components already described.

[0039] The upper thread feeding device 109 does not include the base 37 mounted on the tension table 22, and includes the clamp portion 110, the opening and closing mechanism 140, and the controller (not shown) shown below. This is the same as the first embodiment. The upper thread feeding device 31 is different. In addition, the switching mechanism 35, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com