Feed production quality tracking system

A production quality and traceability system technology, applied in the direction of instruments, data processing applications, resources, etc., can solve problems such as automatic traceability systems that have not been seen, and achieve the effect of ensuring visual control and monitoring source pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1 production planning and product batch management

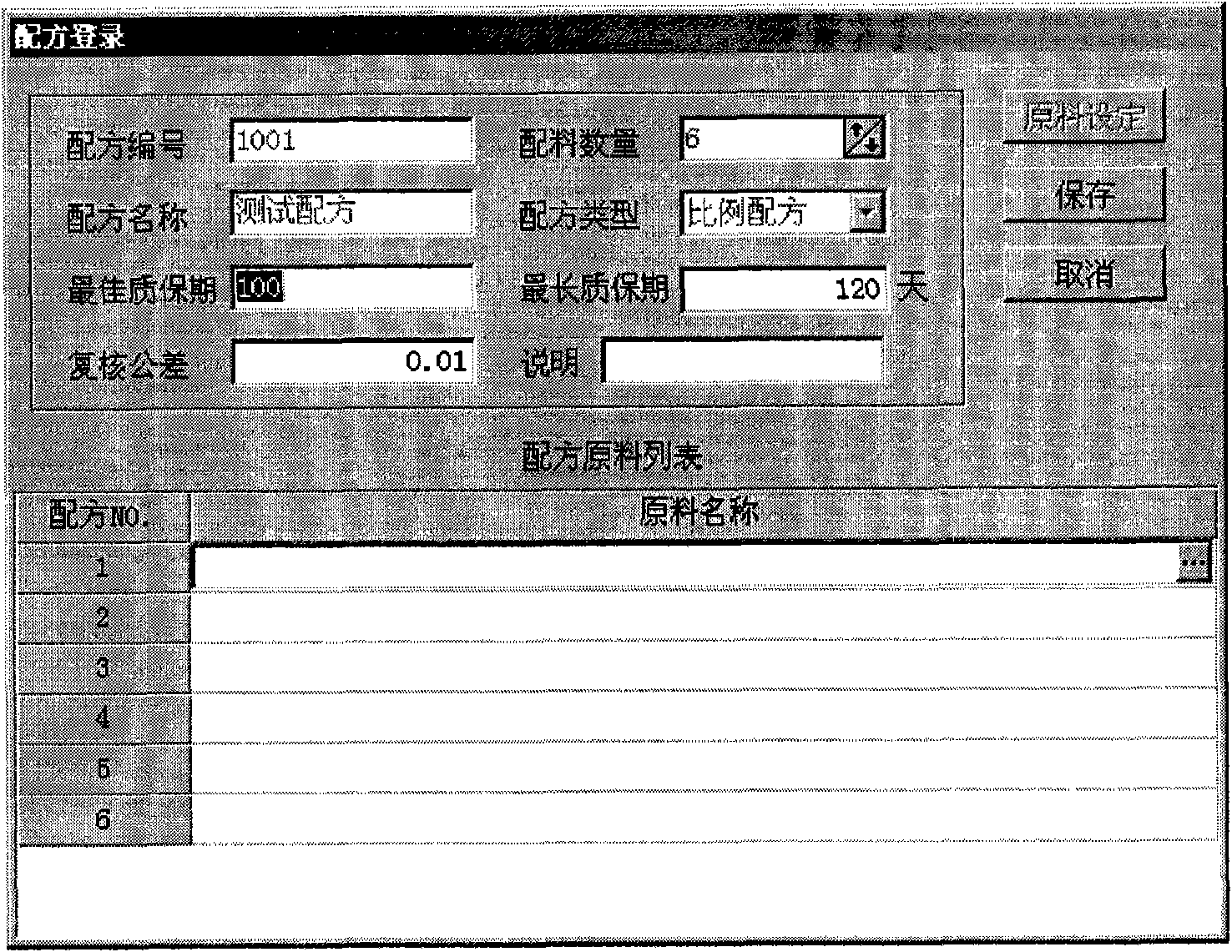

[0069] Production management personnel can enter the operation plan of the day or a certain period of time on the client terminal, including: production formula number, production batch number, production quantity and other information, and workers work according to the production plan. Managers can view production progress and detailed production records. See Figure 4 . Figure 4 It is an interface displayed by a feed production management computer.

Embodiment 2

[0070] Embodiment 2 Feeding control process

[0071] 1. The main control room issues a feeding instruction, and displays at the feeding port terminal: the number and name of the feeding formula, the name, code, and feeding progress of the current feeding raw material.

[0072] 2. Scan the barcode on the feeding identification card.

[0073] 3. Judging whether the order of taking and feeding materials is correct, if there is an error, the red light will warn.

[0074] 4. If correct, feed the mixture.

[0075] 5. The system automatically judges whether the feeding is over. If it is over, the blue indicator light will be on, otherwise the green indicator light will be on.

[0076] 6. The system automatically records the feeding process data for query.

[0077] See flow chart Figure 5 . Figure 5 It is the feeding control process.

Embodiment 3

[0078] Embodiment 3 software system settings

[0079] Feed production control settings are as follows program control software:

[0080] 1. Raw material barcode batch management;

[0081] 2. Ingredients weighing control (multiple weighing points can be expanded according to demand);

[0082] 3. Feeding control (multiple feeding points can be expanded according to demand);

[0083] 4. Finished product batch management;

[0084] 5. Quality traceability;

[0085] 6. Production management;

[0086] 7. Formula maintenance

[0087] Table 2 Features and advantages of the software system

[0088] feature

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com