Novel high-precision electrical electronic Brinell hardness tester

A high-precision, electric technology, applied in the direction of testing the hardness of materials, etc., can solve the problems of easy wear, cumbersome manual control, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

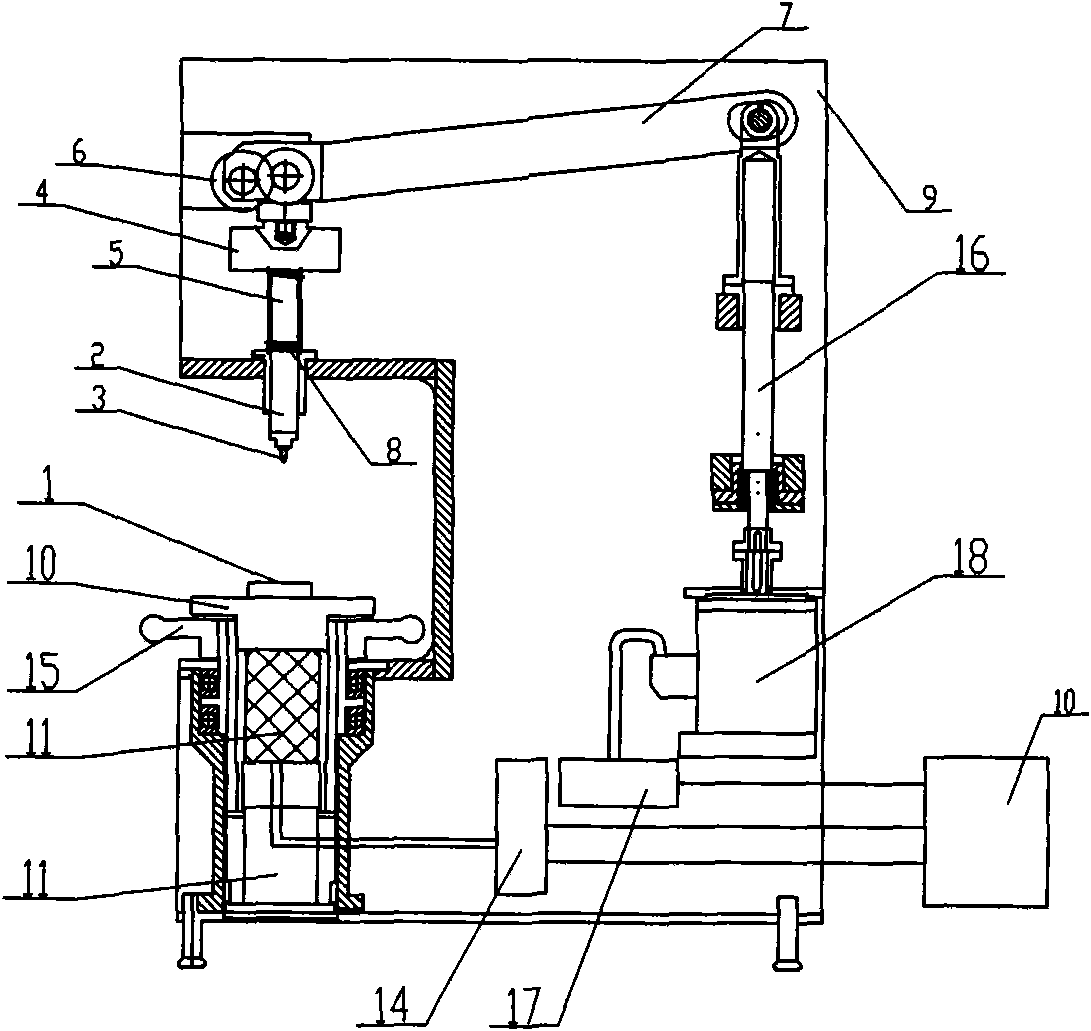

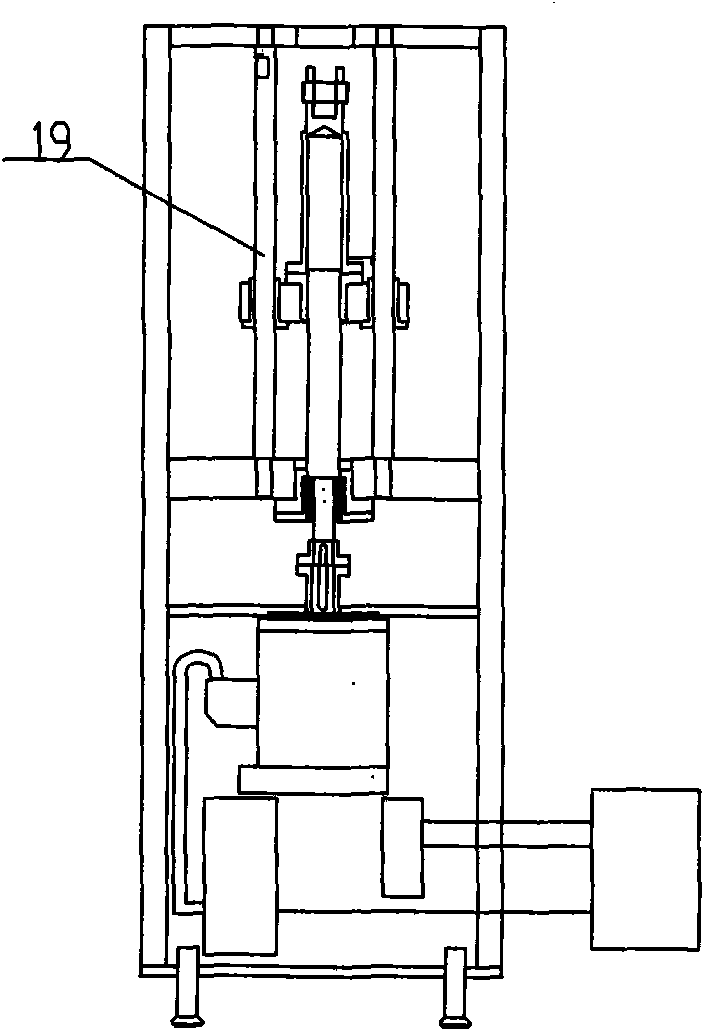

[0009] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0010] See attached Figure 1~2 As shown, this new type of high-precision electric electronic Brinell hardness tester includes a high-rigidity C-shaped body 9, an experimental platform 10, an upper indenter seat 2 and a replaceable indenter 3. The body 9 is not only a load The installation of application, measurement and control equipment provides a platform, and because of the minimal deformation in the working process, it becomes one of the prerequisites for high-precision measurement. The experimental platform 10 is driven up and down by the hand wheel 15 and the screw rod 12. The feature is that it has a working platform 10 set on the machine body 9. The working platform 10 can not only manually adjust the height of the table, but also stop and self-lock at any position required by the experiment. The indenter seat 2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com