Flue gas distributor

A distributor and flue gas technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as complex structure, dead bed formation, poor redistribution effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

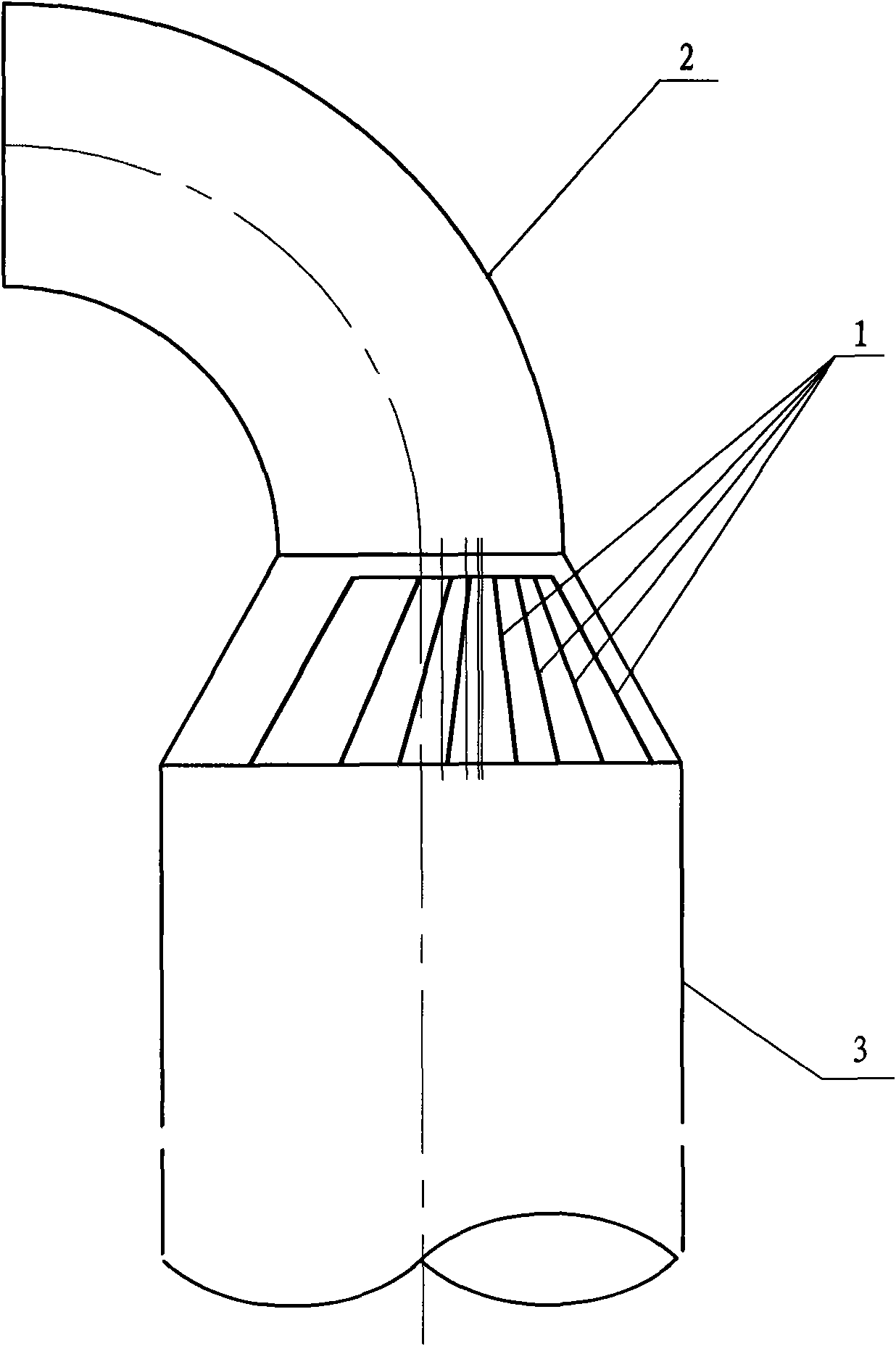

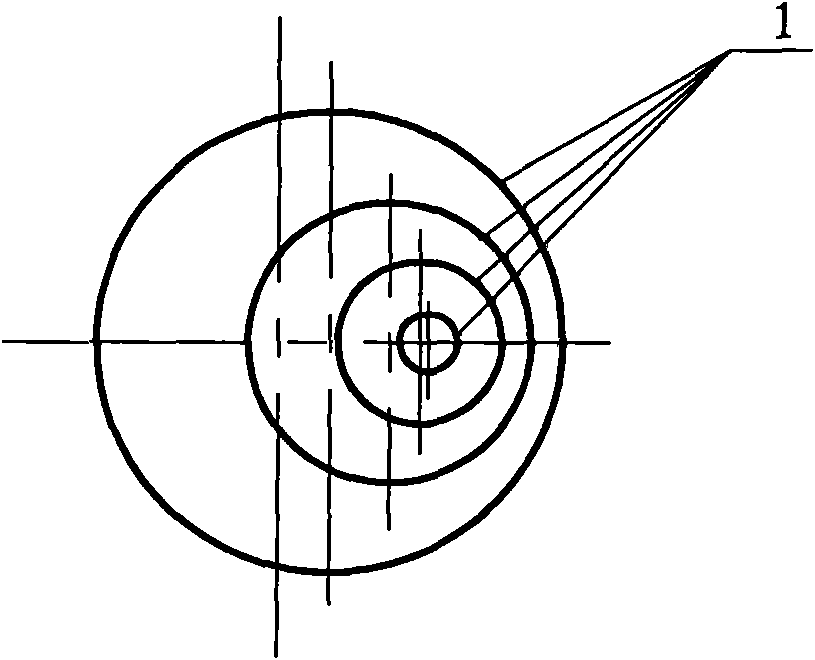

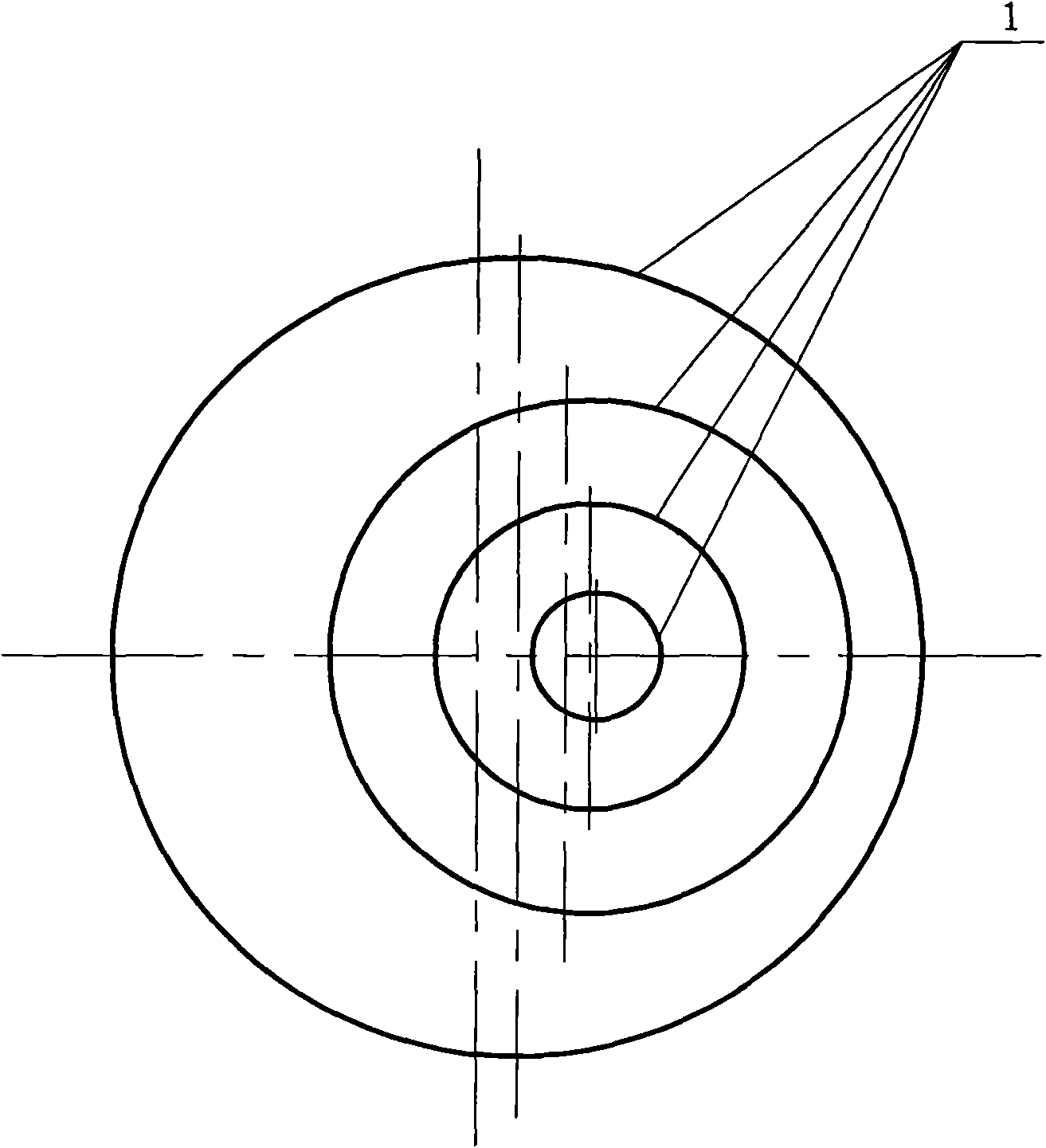

[0009] As shown in the figure, the smoke distributor includes a plurality of conical cylinders 1 with different maximum diameters. The upper end of the conical cylinders with a smaller diameter communicates with the smoke inlet pipe through a section of elbow 2. The conical cylinders The lower end with a larger diameter is connected to the desulfurization tower 3, and each conical cylinder is sequentially set according to the size of the maximum diameter, wherein the center line of the conical cylinder with a smaller maximum diameter is opposite to the conical cylinder with a larger maximum diameter on its periphery. The center line of the cylinder is offset to one side by a certain distance, and the direction of offset is the side close to the larger bending radius of the elbow 2, that is, on the side closer to the larger bending radius of the elbow 2, each The walls of the conical cylinders 1 are relatively dense, while the walls of the conical cylinders 1 are relatively spar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com